The global manufacturing industry is rapidly moving towards intelligence and digitalization. Automation, as the core of this transformation, has led to widespread use of equipment like automatic lamination and unwinding machines in industries such as new energy batteries, electronics, and composites, driving the transition from manual operations to fully automation. However, the complexity and delays in quality inspection remain a key bottleneck that limits further progress.

Portable CMM in Quality Inspection

In early 2020, the new energy vehicle industry gradually came to the fore. A new energy company was facing challenges with low efficiency and high rework rates due to outdated measurement methods, which resulted in limited production and reduced market competitiveness. After multiple visits, a PMT account manager suggested PMT ALPHAM 3.0m portable coordinate measuring machine (CMM), supplemented by folding adjustable tripod. This enabled the company to boost the pass rate of its key equipment, the lamination machine, to over 99.5%.

Core Advantages of PMT ALPHAM portable CMM:

1. Excellent Accuracy: Achieves up to ±0.02mm (In accordance with ISO 10360-12), providing reliable repeatability.

2. Cost-effective Performance: Balances precision and value, ideal for high-speed lamination machines.

3. Smart Integration: Enables real-time data assembly and archiving with PMT portable CMM and 3D software.

Lamination Machine Tooling Setup: Measurement of Pole Piece

“With traditional measurement methods, the pole piece alignment in our machine had a deviation of up to 0.15 mm, leading to a pass rate of just 91.7%. Now, by using a portable CMM with 3D software, we can adjust the pole piece alignment in real time. This has reduced the deviation to ±0.03 mm and boosted the pass rate by more than 7.8%, greatly improving both efficiency and yield,” A production manager from a top lamination machine company just shared.

Measurement Steps:

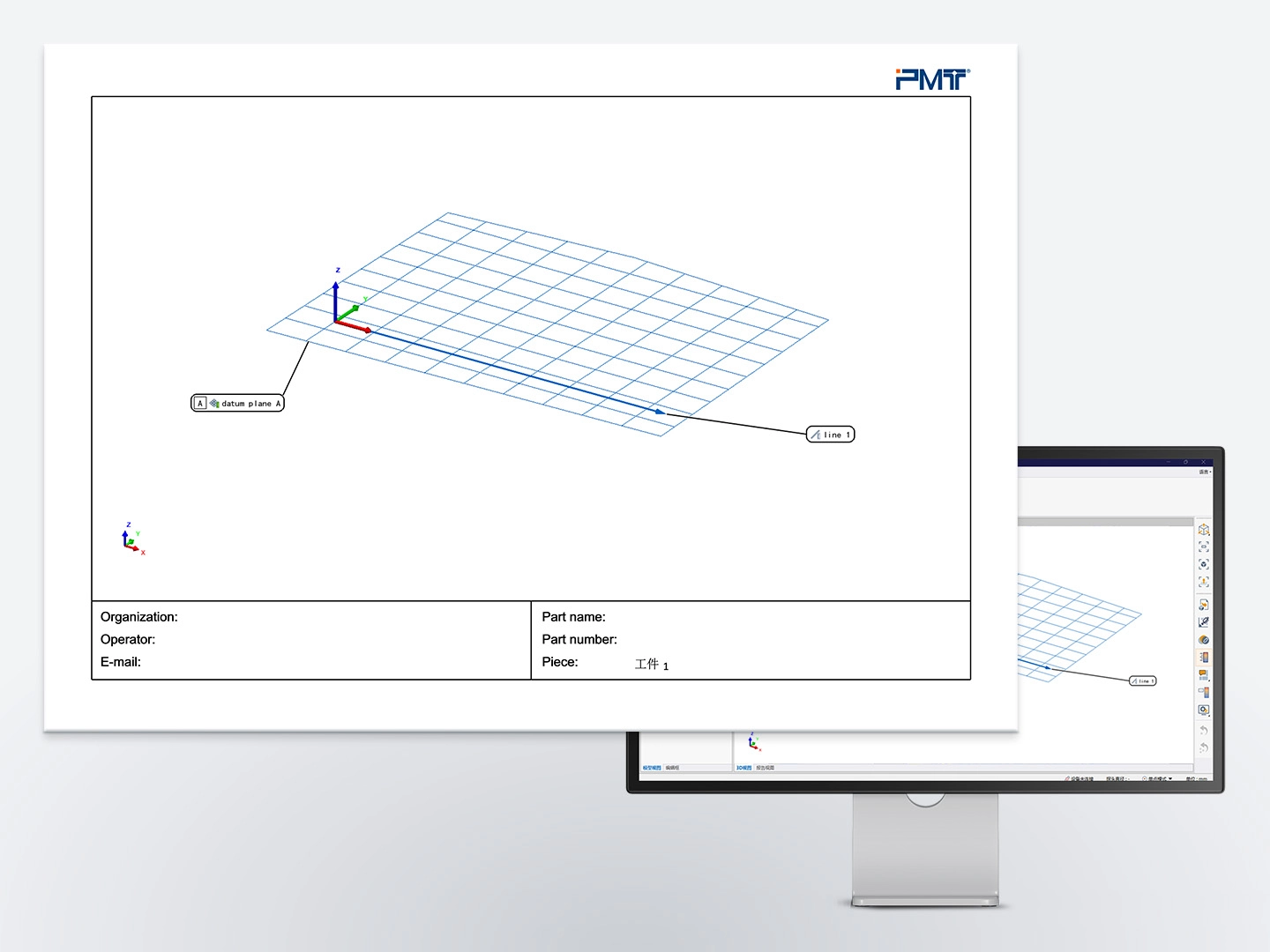

1. Establish the Coordinate System

Take the machine platform as the reference plane and the long side of the machine’s base (or the line of a circular hole) to establish the coordinate system.

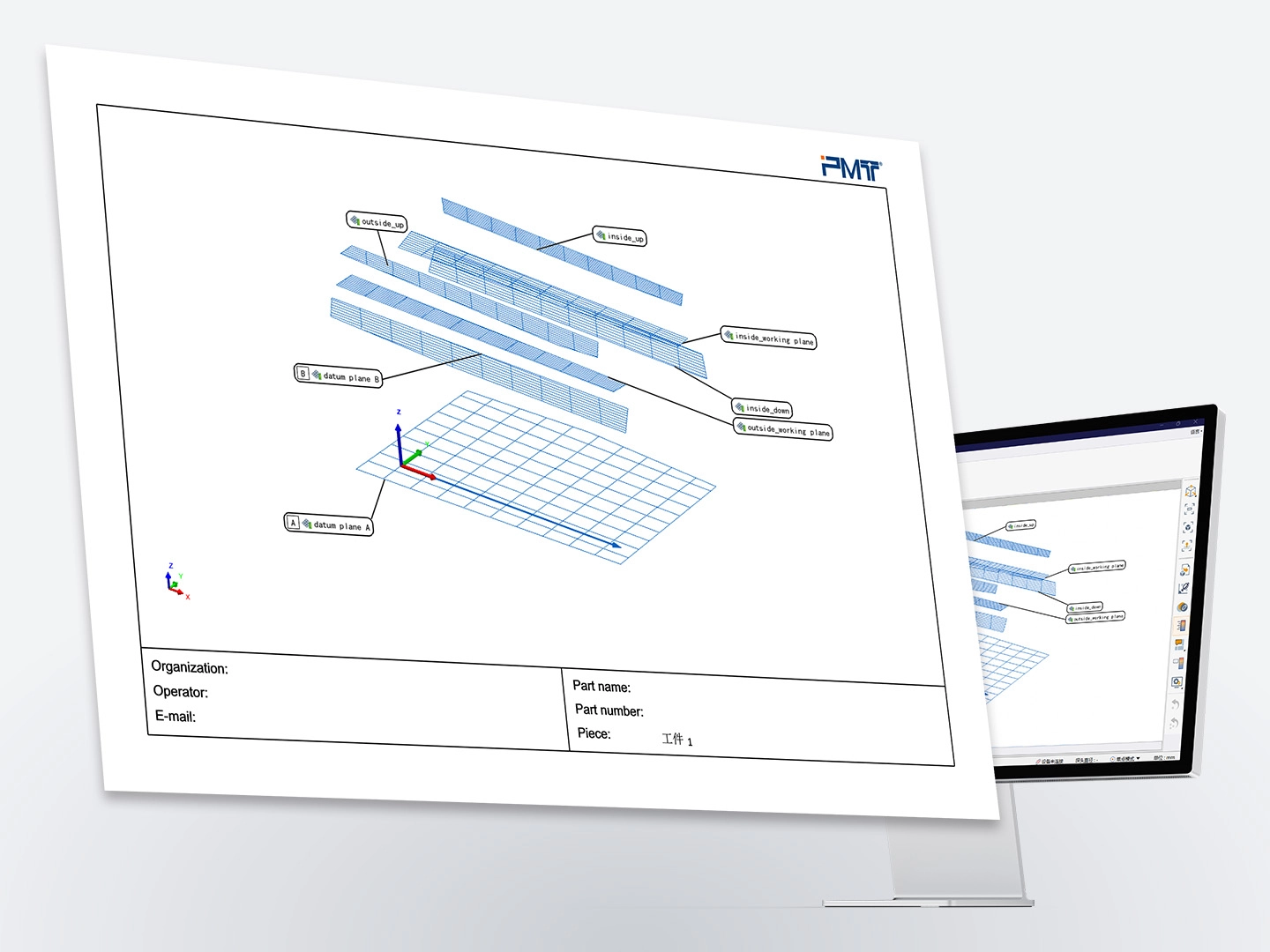

2. Data Acquisition

Use the PMT portable CMM to inspect the flatness, perpendicularity, and parallelism of the mounting surfaces, checking excessive errors for further adjustments.

3. Real-time Adjustment

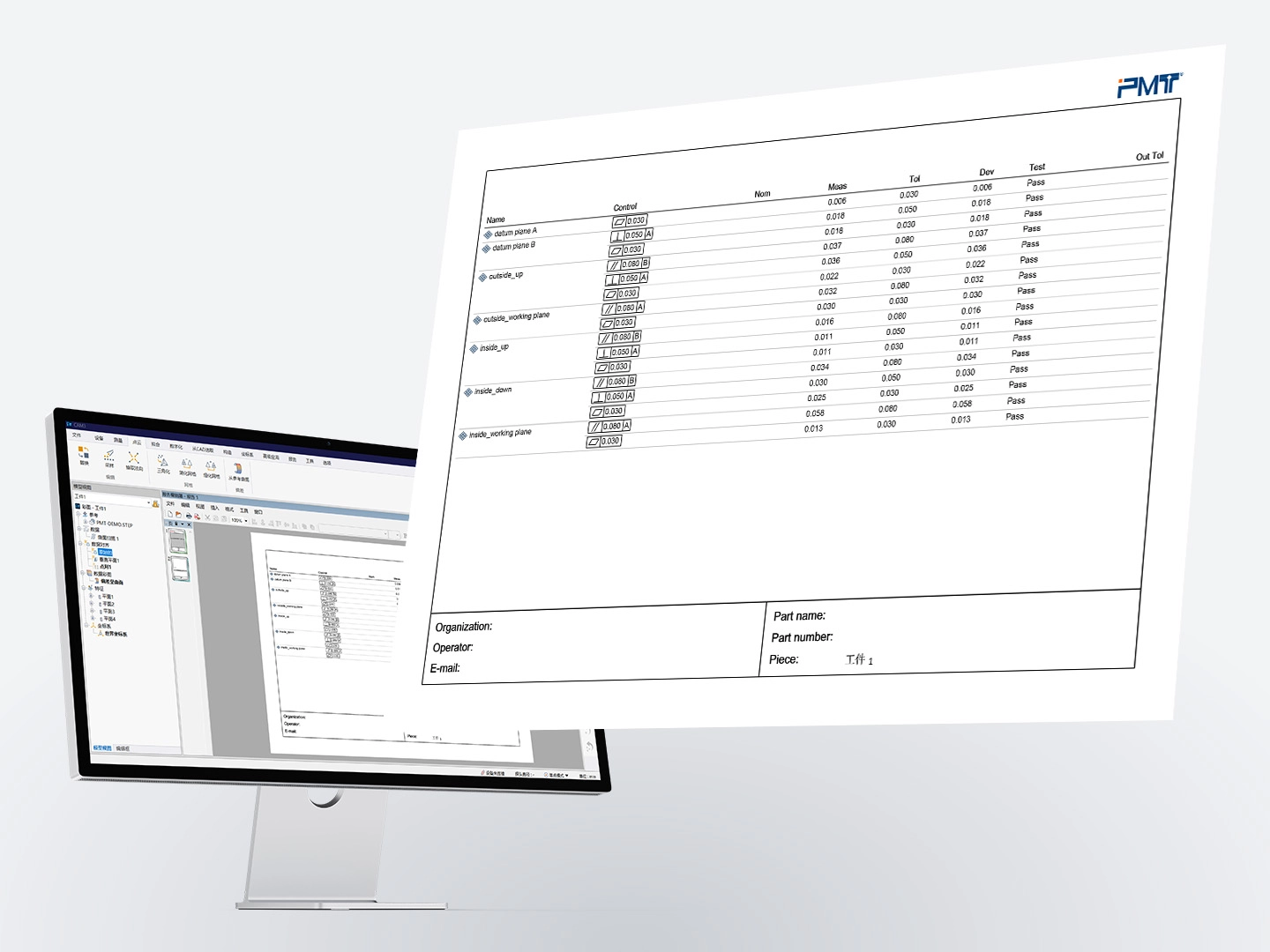

Evaluate the measured data: Green indicates pass, red indicates errors. Correct errors by loosening screws and adjusting gaps until tolerances are within limits.

4. Report Generation

Measure again the features and adjust any remaining errors until all meet requirements. Then the report can be generated and archived for future traceability.

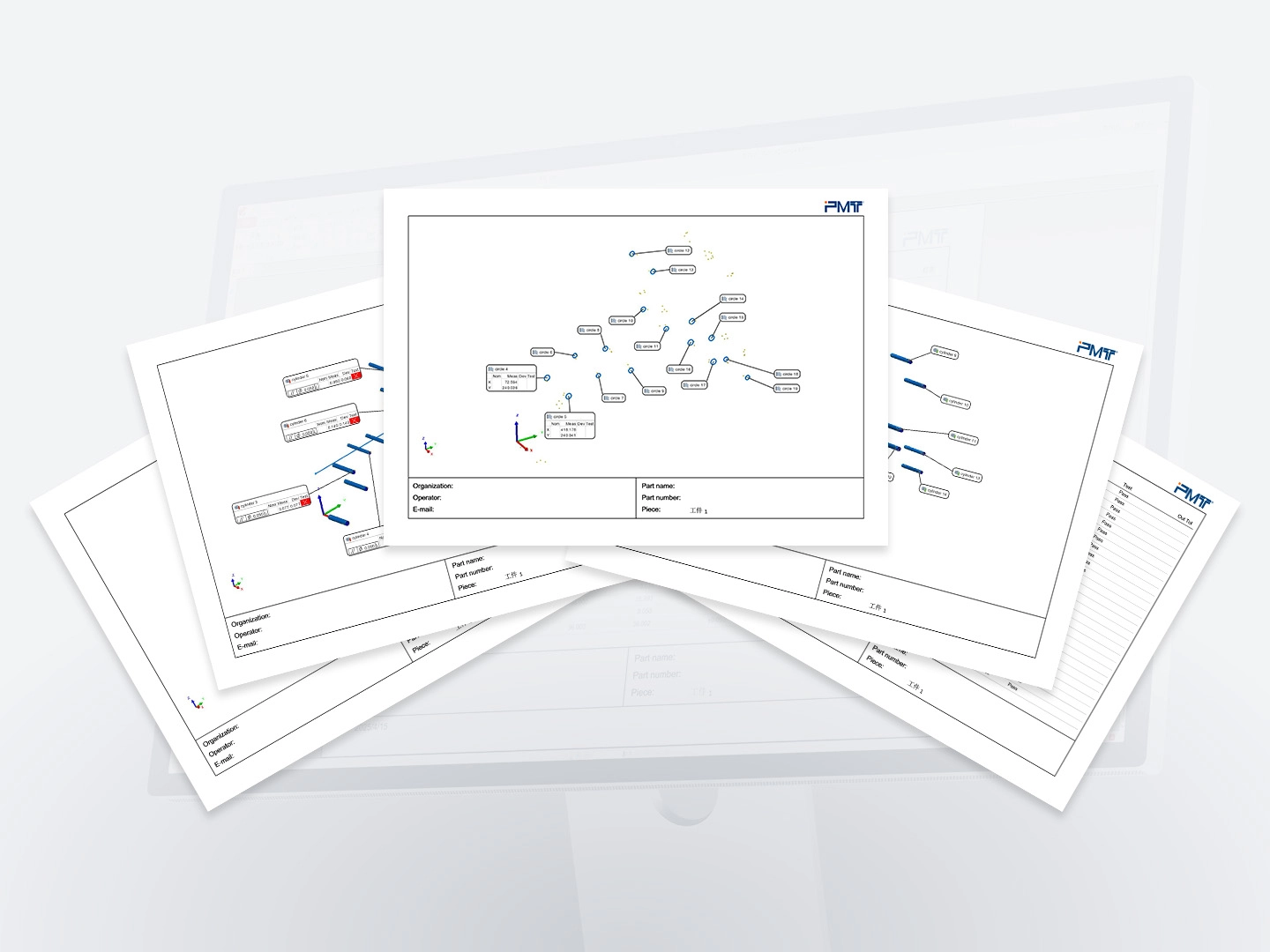

Unwinding Machine Tooling Debugging: Diaphragm Tension Control

During the production of lithium battery, the unwinding machine feeds pole pieces to the lamination machine. Uneven diaphragm tension can cause wrinkles or tears, reducing the stability of the unwinding machine and leading to quality defects.

Building on previous success with the lamination machine, a factory, after discussions with the PMT account manager, decided to use the PMT ALPHA portable CMM to enhance the unwinding machine’s tension system. By measuring roller alignment and adjusting mounting surfaces, diaphragm tension fluctuations were reduced from ±8N to ±1.5N, cutting debugging time by over 65%. This significantly addressed diaphragm wrinkling and tearing, boosting both stability and productivity.

Conclusion

Through the Build/Inspect function in 3D software, the PMT portable CMM pioneers a comprehensive quality control process of “real-time measurement, dynamic feedback, and precise correction”. It helps significantly inject momentum into the automation industry with its cutting-edge accuracy, portability, and flexibility.