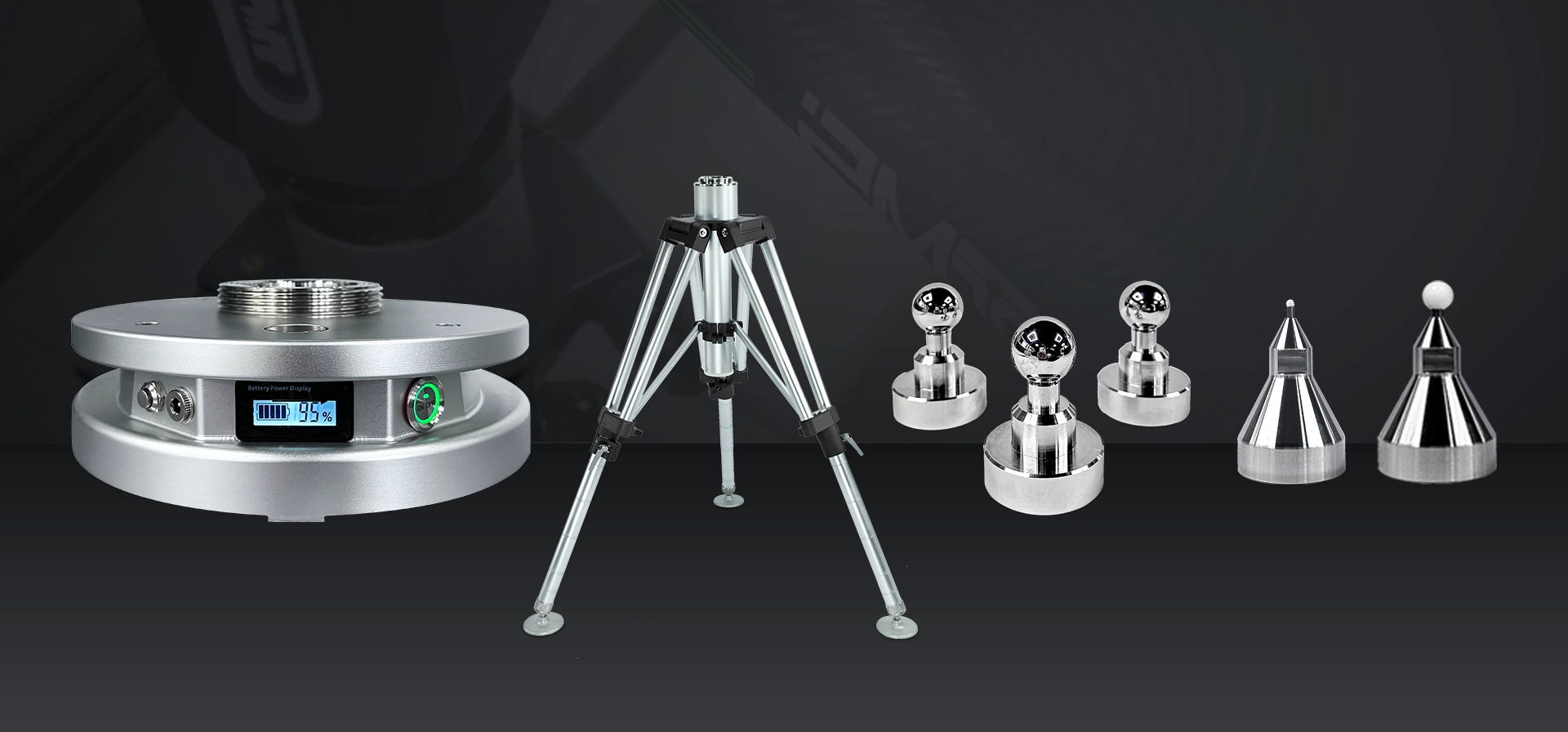

PMT continues to its endeavour to upgrade the products. In 2022, the PMT portable arm has been used in a test program for a new type of unmanned aerial vehicle (UAV) on a snowy plateau. The portable measurement arm is mainly used for on-site assembly and measurement. After 7,200 kilometers, with the support of the PMT measuring arm, the test program achieved a great success.

The program was launched by a scientific research entity in China. The large-scale UAV showed unique performance during the multi-subject field tasks. The PMT measuring arm helps achieve the coordinates for the points of the measured target, and obtain the accuracy and repeatability of the positioning by comparing the coordinate data before and after the movement of the same point. Through probing the hole position and guide rail plane of the bracket, the PMT portable CMM can calculate the relative position of the bracket hole position, and the parallelism and perpendicularity between the guide rail surfaces so as to allow adjustments in a timely manner during installation. More details about the program are not disclosed, due to security concerns.