The post PMT Joins the 2025 GPS Standardization Conference to Discuss Precision Measurement appeared first on PMT Technologies.

]]>

The conference gathered committee members from across the country, including standard drafting group members, scholars from research institutes, experts from authoritative testing agencies, and representatives from leading companies. The event officially opened on the morning of December 26, with a formal introduction of the leaders and guests, followed by speeches from the Secretary-General and the President of the China Academy of Machinery Science and Technology.

Key Agenda Highlights

- Rigorous Review: The committee reviewed and approved the 2025 Annual Work Summary and the forward-looking 2026 Annual Work Plan.

- Standards Introduction: The latest developments and trends from ISO/TC 213 were presented in detail.

- Proposal Sharing: A session was held to showcase new standard proposals, emphasizing the ongoing optimization of technological exploration.

- In-depth Interpretation: High-quality standardization training was provided, offering a comprehensive interpretation of the “Regulations on the Administration of National Standardization Guiding Technical Documents,” serving as key guidance for national standards.

- Thorough Review: Fifteen national standard drafts, including the highly anticipated “GPS Surface Structure: Profiling Method Part 1: Representation of Surface Structure,” underwent detailed technical reviews.

Enhancing Capabilities: Leading Experts Share Cutting-Edge Technology

At the conference, renowned experts from the industry shared insights on advanced technologies, including:

Wu Jinjie, from the National Institute of Metrology, gave an in-depth presentation on grating dimension measurement technology.

Sun Anbin, from the Changcheng Institute of Metrology & Measurement (CIMM), discussed photogrammetry based on standard surfaces.

Huang Jingzhi, from Harbin Institute of Technology, provided an academic perspective on coaxial 3D measurement technology.

Zhang Xiangchao, from Fudan University, introduced digital holographic microscopy technology.

PMT Highlights: Portable Measuring Arm Sparks Industry Interest

At the technical exhibition, PMT showcased its self-developed high-end portable measuring arm, which impressed industry experts with its precision, flexibility, and reliability. The superior performance of the arm sparked considerable attention from experts and institutes, with many expressing recognition for PMT’s portable 3D measurement technology.

Through these interactions, PMT recognized that while our technology is well-known within the industry, broader brand awareness remains limited. This realization has strengthened our resolve to further advance in the measurement field and solidify our position as a leader in portable measurement technology.

Pioneering the Future: PMT’s Dedication to Leading Portable Measurement

On December 27, the conference concluded successfully. Through engaging with top experts and users, PMT further solidified its technological reputation within the industry. Meanwhile, our team gained a deeper understanding of national dimensional specification standards, enhancing our members’ professional capabilities. This experience has reinforced our commitment to becoming a pioneering force in China’s high-end instrument sector, an unwavering direction for our future growth.

The post PMT Joins the 2025 GPS Standardization Conference to Discuss Precision Measurement appeared first on PMT Technologies.

]]>The post A Year of Recognition and Growth: PMT’s 2025 Global Review appeared first on PMT Technologies.

]]>Dual Engines of Growth: R&D and Manufacturing

At PMT, research and development and manufacturing are viewed as two equally important engines of long-term growth. In 2025, the company continued to strengthen both.

On the R&D side, PMT optimized product design processes and diversified supply channels to improve flexibility and resilience. At the same time, production lines were upgraded and expanded through the introduction of new equipment and advanced manufacturing processes. These investments were made with a clear goal: to shorten the distance between innovation and delivery.

By closely aligning production planning with customer delivery schedules, PMT improved execution efficiency and responsiveness. This dual-engine approach allowed the company to bring advanced metrology solutions to market faster while maintaining high quality and consistency.

Recognition and Certification: Proof of Reliable Capability

2025 was also a year of strong recognition for PMT’s technical strength and management systems. The company continued to grow its portfolio of proprietary invention patents, reinforcing its foundation of independent innovation.

PMT maintained full compliance with international standards and certifications, including ISO 9001, CE, RoHS, IP54, and PTB. These certifications ensure that PMT products meet global requirements for quality, safety, and reliability.

In terms of honors, PMT achieved several important milestones. The company was recognized as a national high-tech enterprise and received multiple regional and industry awards. Most notably, PMT was named a national-level “Specialized, Sophisticated, and Innovative ‘Little Giant’ Enterprise” in 2025. These recognitions reflect PMT’s consistent focus on precision, specialization, and sustainable growth.

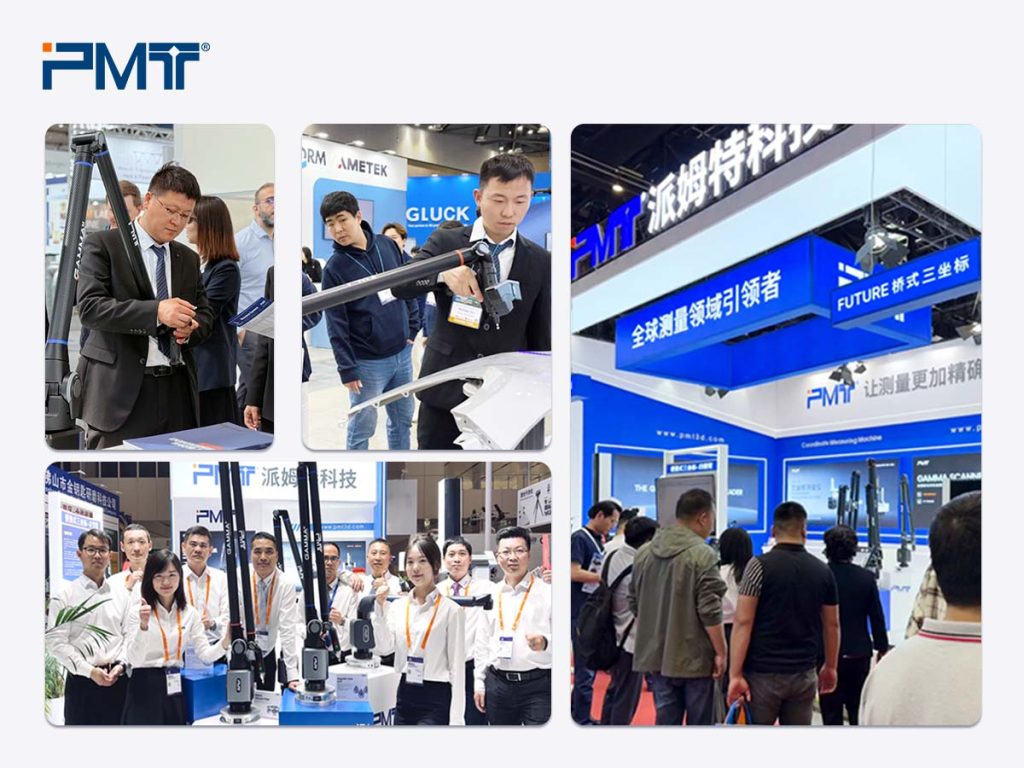

Global Industry Engagement Through Exhibitions

Throughout 2025, PMT actively participated in major industrial exhibitions across key global markets. These events served not only as showcases for PMT’s latest technologies but also as platforms for direct, in-depth exchange with customers and industry peers.

Highlights included INTERMOLD Seoul, where PMT strengthened engagement with the Korean market; ITES Shenzhen, a key platform for connecting with the precision manufacturing community in South China; CIMT Beijing, one of the world’s most influential machine tool exhibitions; and Control Stuttgart, a global benchmark event for quality assurance and metrology technologies.

Through these exhibitions, PMT shared practical solutions, discussed real manufacturing challenges, and reinforced its role as a value-driven measurement technology partner.

Expanding Global Footprint Through Open Collaboration

In 2025, PMT continued to expand its global presence with an open and collaborative approach. In China, the company refined its customer-centric service system, strengthening the professionalism and responsiveness of sales, technical, and after-sales teams. A standardized customer reception process at the headquarters now allows visiting clients to experience PMT’s production capabilities and quality standards firsthand.

Internationally, PMT made significant progress. During the year, the company established new partnerships and successfully delivered projects in 16 countries, including Canada, the United States, Thailand, Vietnam, Egypt, Ireland, Hungary, Slovakia, Peru, and Pakistan. In addition, PMT deepened cooperation with partners in more than 50 countries worldwide.

Notably, PMT’s FUTURE and PRIME series Coordinate Measuring Machines were delivered to markets as far as South Africa, receiving positive feedback and high recognition from international partners.

Message from the President: Staying Close to Customers

“Being customer-centric means more than meeting requirements—it means understanding what customers truly care about,” said Tom Tai, President of PMT. Manufacturing environments are complex, and challenges are constant. As a provider of integrated hardware and software solutions, PMT understands these realities.

In 2025, PMT focused on responding with empathy, speed, and responsibility. Looking ahead to 2026, the company remains committed to supporting customers with the same dedication and trust, delivering solutions that address real production needs.

Looking Ahead: Moving Forward with Confidence

Technology continues to shape the pace of industrial transformation. In 2025, PMT strengthened its foundations; in 2026, the company is ready to move faster and further.

With continued innovation, expanded product lines, and a clear focus on customer value, PMT enters the new year prepared to face greater challenges and seize broader opportunities. The journey continues—driven by precision, powered by innovation, and guided by partnership.

The post A Year of Recognition and Growth: PMT’s 2025 Global Review appeared first on PMT Technologies.

]]>The post Precision Gear Inspection in Heavy Equipment Manufacturing appeared first on PMT Technologies.

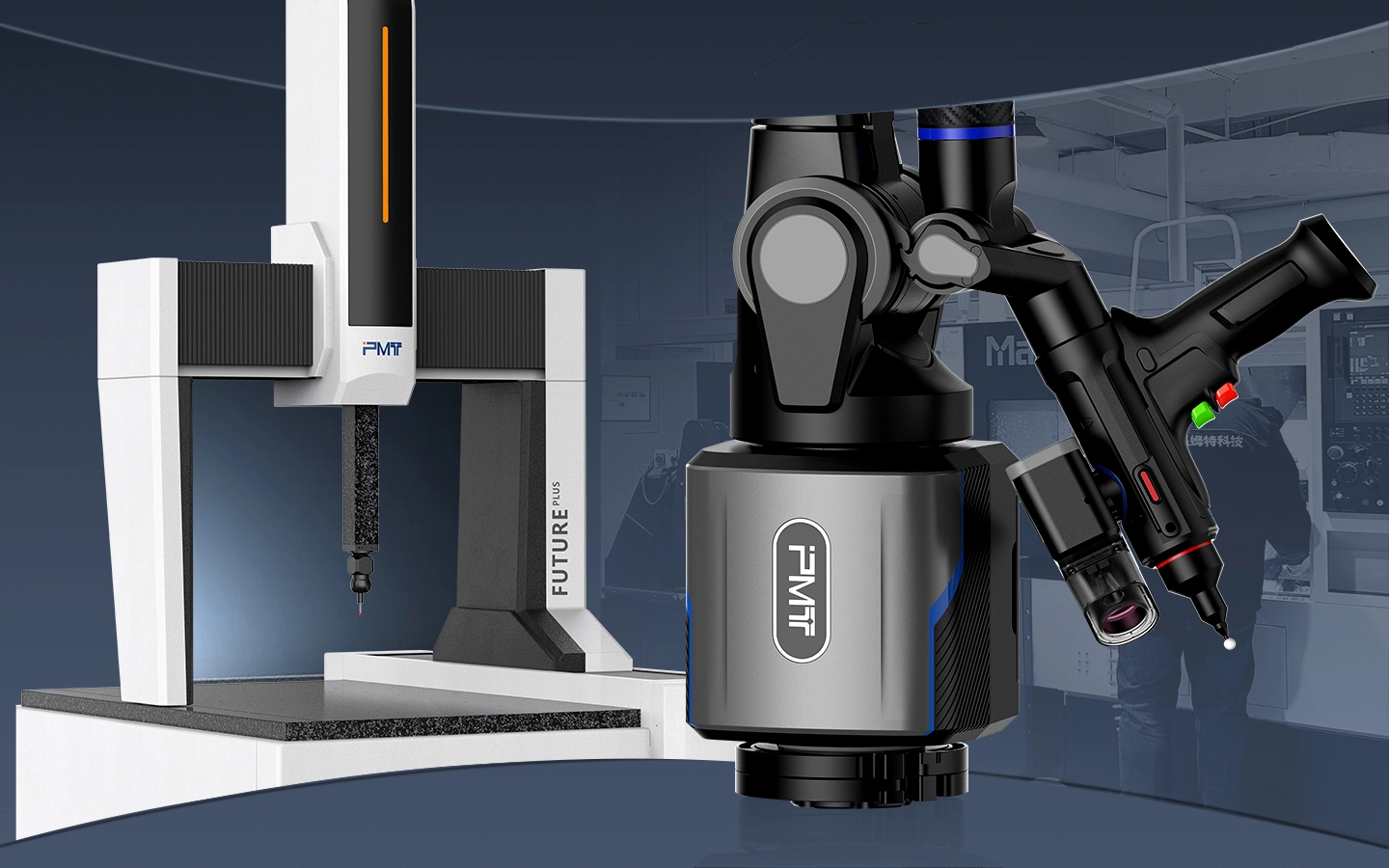

]]>To meet increasingly strict quality standards, manufacturers are turning to advanced coordinate measuring machine (CMM) solutions that deliver both accuracy and efficiency. This case highlights how a PMT FUTURE Bridge CMM, combined with professional measurement software, supports high-precision spiral bevel gear inspection in a demanding industrial environment.

Project Background

The customer is a foreign-invested enterprise with long-term expertise in heavy equipment manufacturing. Its business covers the research, design, production, sales, and technical services of core industrial equipment, including tube rolling mills and related transmission systems.

Within these systems, spiral bevel gears are key functional components. They are responsible for precise torque transmission and 90-degree directional changes under heavy loads. Due to their critical role, the customer maintains a strict internal quality control system, particularly for gear geometry and form-and-position tolerances.

To further strengthen inspection capability and ensure stable gear performance during assembly and operation, the customer partnered with PMT to implement a high-precision CMM-based measurement solution.

Clear Measurement Objectives Before Inspection

Before formal inspection, PMT engineers carefully reviewed the customer’s technical drawings to confirm all required measurement features. Based on the functional requirements of the spiral bevel gear, the inspection objectives were clearly defined in advance to ensure that all measured results directly support assembly and operational performance.

The key measurement objectives included:

- Perpendicularity

Inspected to avoid assembly tilt between mating components. Accurate perpendicularity helps ensure proper alignment and reduces uneven load during operation. - Parallelism

Controlled to prevent vibration and performance degradation. Poor parallelism can negatively affect machining accuracy and long-term transmission stability. - Coaxiality

A critical parameter for spiral bevel gears. Accurate coaxiality ensures stable meshing and reliable power transmission. In this application, coaxiality accuracy reached up to 1 μm. - Total Runout

Measured to detect potential part defects and form deviations. Controlling total runout helps ensure smooth rotation and stable operation of the transmission system.

By clearly defining these objectives at the beginning, PMT ensured a focused, efficient, and application-oriented inspection process.

PMT CMM Solution for Spiral Bevel Gears

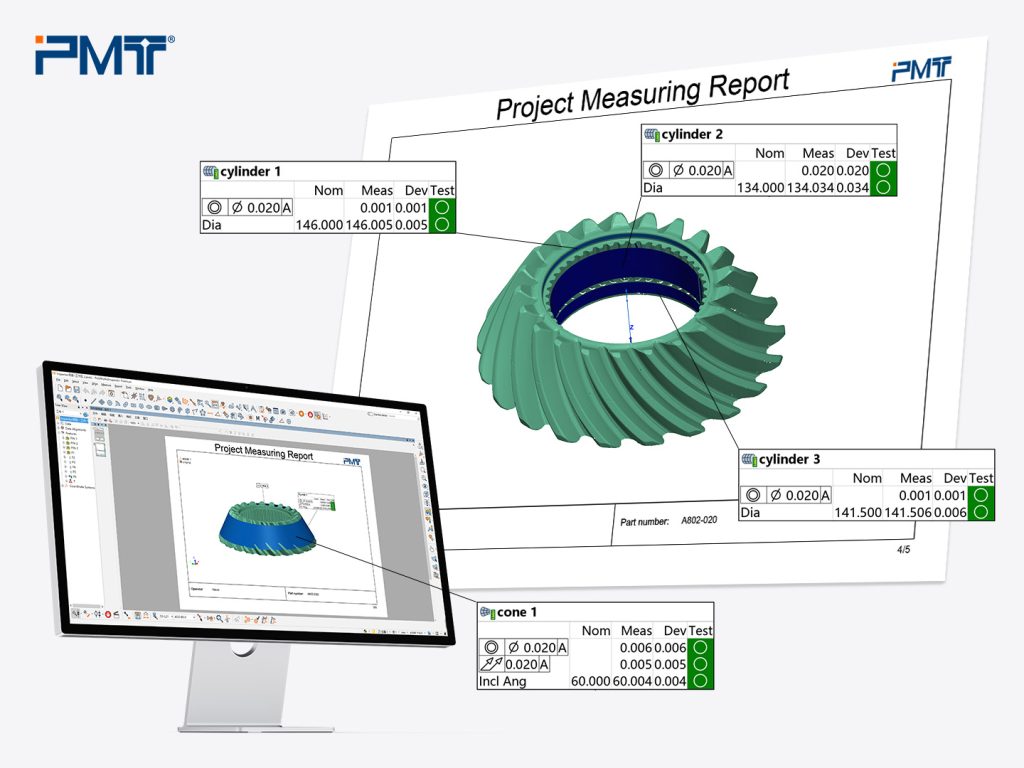

To address these inspection challenges, the customer adopted a PMT FUTURE Bridge coordinate measuring machine integrated with professional measurement software.

The bridge-type CMM structure provides excellent rigidity and stability, making it well suited for high-precision industrial measurement tasks. Combined with advanced probing and software analysis capabilities, the system enables comprehensive evaluation of complex gear geometry in a single setup.

Outstanding Accuracy Performance

One of the key reasons the customer selected PMT was its proven accuracy performance.

Using the PMT FUTURE Bridge CMM, the system achieves coaxiality measurement accuracy down to 1 μm, allowing even the smallest deviations to be reliably detected. This level of precision ensures that spiral bevel gears meet strict assembly and meshing requirements, supporting stable transmission performance in heavy-duty applications.

High repeatability further guarantees consistent inspection results across multiple parts, reinforcing confidence in quality decisions.

Efficient and Comprehensive Inspection

Beyond accuracy, inspection efficiency was another important consideration.

With PMT’s CMM solution, multiple form and position tolerances—including perpendicularity, parallelism, coaxiality, and total runout—can be inspected within a single measurement program. This approach significantly reduces inspection time compared with traditional measuring tools, which often cannot evaluate these parameters effectively or consistently.

The result is a streamlined inspection process that improves productivity while maintaining high measurement reliability.

Fast Analysis and Data-Driven Quality Control

The integration of measurement software further enhances inspection efficiency and usability.

Measurement results are automatically transformed into clear, visualized inspection reports, allowing engineers to quickly understand part quality status. In addition, the system supports SPC (Statistical Process Control), enabling long-term trend analysis and process optimization.

This data-driven approach helps the customer move beyond pass/fail judgments and toward continuous quality improvement.

Applications Across Multiple Industries

Spiral bevel gears are widely used across industrial sectors due to their high efficiency, load capacity, low noise, and compact 90-degree transmission design. Typical application areas include:

- Automotive manufacturing

- Machine tools

- Heavy machinery

- Shipbuilding

- Wind energy systems

- Aerospace and defense

The PMT CMM solution demonstrated in this project is well suited for these industries, where both precision and reliability are essential.

Conclusion

This project demonstrates how PMT’s FUTURE Bridge CMM, combined with advanced measurement software, delivers a reliable and high-precision solution for spiral bevel gear inspection. With coaxiality accuracy reaching 1 μm, efficient multi-tolerance inspection, and powerful data analysis capabilities, the solution fully supports the stringent quality requirements of heavy equipment manufacturing.

By enabling accurate, repeatable, and efficient measurement, PMT helps manufacturers ensure stable gear performance and long-term equipment reliability.

About PMT

PMT is a professional coordinate measuring machine supplier dedicated to providing high-precision metrology solutions for industrial manufacturing. With a strong focus on accuracy, efficiency, and practical application, PMT supports customers worldwide in achieving reliable quality control and smarter production processes.

If you are looking to enhance gear inspection or optimize critical component measurement, PMT is ready to support your next step in precision manufacturing.

The post Precision Gear Inspection in Heavy Equipment Manufacturing appeared first on PMT Technologies.

]]>The post PMT Showcases Portable Measurement Solutions at AIMC 2025 appeared first on PMT Technologies.

]]>On November 30, 2025, the Aerospace Equipment Intelligent Manufacturing Innovation and Development Conference (AIMC) wrapped up in Shandong province, hosted by the People’s Government of Fushan District, Yantai City, and Nanjing University of Aeronautics and Astronautics. With the theme “Intelligent Manufacturing Leads the Future of Aerospace,” the conference attracted over 350 experts, academics, and enterprises, with PMT invited as a key player in high-precision 3D measurement technologies.

Live Demos Highlight the Power of Measuring Arms

In the technical exhibition zone, PMT conducted dynamic on-site demonstrations, showcasing the core capability of its portable measuring arm solutions: performing accurate measurement anytime, anywhere.

The demonstration featured the scanning and inspection of typical aerospace components. It clearly displayed the outstanding performance of PMT’s blue light scanners integrated with the GAMMA and ALPHA measuring arms. These portable arms excel in high precision, high efficiency, and true portability. What’s more, PMT’s Portable CMM Arm solution is capable of capturing complex surfaces, comparing inspection data with CAD models in real-time, and generating reports rapidly. The versatility of the PMT Arm was also highlighted by its detachable 3D scanners, which enhance measurement accuracy and broaden the scope of inspections across various aerospace applications.

PMT’s Technological Leadership Sparks Industry Dialogue

During the event, PMT’s booth attracted a continuous stream of visiting experts. Mr. Chen Zhonggui, Researcher at the China Academy of Space Technology and Chief Designer of the Beidou-3 satellite, held an in-depth and productive discussion with PMT’s Founder and CEO, Tom Tai. They explored specific measurement challenges in aerospace quality control, first-article inspection, and other areas. PMT’s independent technological capabilities in providing portable measurement solutions generated strong interest from many enterprises seeking to build efficient and secure digital inspection loops, laying a solid foundation for potential future collaboration.

Insights into Advanced Technologies and Industry Trends

The conference agenda focused on three core areas: “Advanced Forming, Intelligent Manufacturing, and Smart Inspection,” featuring high-level keynote speeches and expert reports.

To bolster innovation in domestically developed technologies, discussions on intelligent manufacturing covered critical topics such as customization for non-standard aerospace components and key CNC machining technologies. A consistent emphasis was placed on the practical application and indispensable role of intelligent inspection—powered by tools like portable coordinate measuring machines—within integrated product design, manufacturing, and production lines.

Conclusion: PMT’s Role in the Future of Aerospace Manufacturing

PMT’s participation in AIMC 2025 not only showcased its leading-edge portable measuring arms but also reinforced its commitment to driving innovation in the aerospace sector. By offering highly accurate and portable measurement solutions, PMT is positioned as a leader in precision measurement technology, playing a vital role in the future of intelligent aerospace manufacturing. The event also laid the foundation for future collaborations, reinforcing the importance of continued innovation and partnerships in the rapidly evolving aerospace industry.

The post PMT Showcases Portable Measurement Solutions at AIMC 2025 appeared first on PMT Technologies.

]]>The post METALEX 2025 RECAP | PMT Measuring Arm Solutions Shine in Southeast Asia appeared first on PMT Technologies.

]]>advanced portable measurement technologies. With the debut of the GAMMA and ALPHA series portable measuring arms, PMT drew widespread attention from global manufacturers and strengthened its presence in Southeast Asia.

Exhibition in Review

From November 19 to 22, METALEX 2025 brought together industry leaders from machine tools, precision engineering, and intelligent manufacturing. The event closely aligned with PMT’s mission of driving industrial upgrading

through technological innovation.

During the exhibition, PMT engineers conducted live demonstrations of measuring arm showing visitors how the portable coordinate measuring machines performed in real-world applications such as complex surface scanning, on-site

inspection, and reverse engineering. These hands-on presentations allowed audience members to directly experience the stability, accuracy, and efficiency of PMT portable measuring arms.

Highlights from the Event

Solving Real Industry Problems

Throughout the show, visitors frequently raised questions such as:

- How can we inspect curved components on-site?

- How do we verify tolerances on large or complex assemblies?

PMT measuring arms provided clear and practical answers.

The GAMMA and ALPHA series feature PMT’s signature external decoupling and internal balancing structure, as well as a dual-support joint design, enabling smooth, lightweight operation and high-accuracy measurements.

With dual-mode capability—hard probing + laser scanning—the portable CMMs reach deep features for complete dimensional inspection while capturing dense point-cloud data for surface analysis. This combination enables rapid and

accurate measurements directly on the shop floor, reducing dependence on laboratory environments and enhancing production efficiency.

Software That Enhances Productivity

Another highlight was PMT’s self-developed measurement software, PMT Inspect.

Its intuitive workflow and comprehensive analysis tools gained positive feedback from many first-time users who tested the system on-site.

Several visitors noted:

“The software interface is very easy to understand. Generating inspection reports with one click is extremely helpful for production-line quality control.”

The seamless combination of hardware and software demonstrated PMT’s commitment to delivering complete and user-friendly metrology solutions.

Connecting with Southeast Asia

METALEX 2025 also marked a significant step in strengthening PMT’s international network.

Manufacturers and industry professionals from Thailand, Vietnam, Malaysia, Indonesia, and other Southeast Asian regions visited PMT’s booth for in-depth technical discussions. The team received strong cooperation interest,

reflecting the increasing demand for portable and flexible measurement equipment in the region.

A Thai molding manufacturer shared:

“PMT measuring arm shows impressive stability and precision. The system fully meets the standards of advanced international brands.”

Such feedback further validated the global competitiveness of PMT’s solutions.

A Strong Conclusion to a Successful Exhibition

The successful presence at METALEX 2025 showcased not only PMT’s measurement capabilities but also the company’s growing influence in the Southeast Asian market. Through direct interaction with international customers, PMT

gained valuable insights into regional needs, which will guide future product development and strategic planning.

As a company with more than 20 years of experience in coordinate measuring machines, PMT remains committed to innovation, customer-focused engineering, and continuous improvement. The team will continue providing advanced

portable measurement solutions for global manufacturing—looking forward to meeting industry partners again at the next major event.

The post METALEX 2025 RECAP | PMT Measuring Arm Solutions Shine in Southeast Asia appeared first on PMT Technologies.

]]>The post Precision That Drives Progress: How PMT CMM Helps Chengxin Machinery Achieve Smart Manufacturing appeared first on PMT Technologies.

]]>

Chengxin Machinery: From Traditional Production to Intelligent Manufacturing

Located in Guangxi, China, Chengxin Machinery (formerly a state-owned enterprise) has been part of the Yuchai Group for over 60 years. The company specializes in high-precision components such as diesel engine connecting rods, gear covers, and key internal combustion parts.

In recent years, Chengxin has moved beyond traditional machining and entered the field of industrial robot integration, marking a major step toward intelligent manufacturing. However, with this transformation came a familiar challenge—how to maintain high quality while increasing efficiency and controlling costs.

The Challenge: Assembly Misalignment in Robotic Components

During the assembly of robotic parts, Chengxin’s inspection team discovered a recurring issue: some of the robot’s second-axis rotating bases (turntables) were difficult to align with positioning pins, and a few connecting bolts tended to loosen after installation.

To find the root cause, the team needed to verify whether key machining dimensions of the second-axis turntable were within tolerance limits. Precise measurement was essential to understand the misalignment and optimize the process.

It became clear that a highly accurate, stable, and efficient coordinate measuring machine (CMM) was required. After thorough evaluation, Chengxin decided to acquire one through a public tender.

Why Chengxin Chose PMT

Among several international and domestic competitors, PMT’s FUTURE PLUS 1587 CMM stood out after a detailed technical comparison and on-site testing. The decision was driven by four key strengths:

1. Higher and More Stable Accuracy

The FUTURE PLUS series uses advanced photoelectric scales and a precision transmission system to achieve micron-level accuracy. It met Chengxin’s strict requirements, including:

- Measurement accuracy within 2.1 + 3.3L/1000 μm

- Scanning error less than 3.5 μm

- GN evaluation and offline programming support

2. Excellent Cost Performance

PMT’s independently developed precision assembly technology delivers European-level quality at a highly competitive price, offering the perfect balance between performance and investment.

3.Reliable After-Sales Service

With a strong service network and rapid response capability, PMT ensures that Chengxin receives timely technical support and continuous operation stability throughout the product’s lifecycle.

4.Secure and Controllable Technology

Unlike many imported systems, PMT provides domestically developed measurement software and control systems, ensuring full data security and system independence—an important factor for companies with global strategies.

The Solution in Action: Measuring the Robot’s Second-Axis Turntable

Using the FUTURE PLUS 1587, Chengxin engineers conducted a complete inspection of the turntable’s geometric features. Key dimensions such as flatness, perpendicularity, concentricity, and distance between holes were measured with micron-level precision.

The setup included:

- Hardware: FUTURE PLUS 1587 (800 × 1500 × 700 mm measuring range)

- Software: Metrolog X4 + PMT Inspect

- Control System: Renishaw UCC S3 Kit

- Probe System: Renishaw PH10M with SP25 scanning probe

The machine’s flexible probe combinations allowed the team to measure deep holes and complex surfaces that were previously difficult to reach. With automatic scanning and software-based evaluation, Chengxin obtained a complete data map of the part’s accuracy.

Results: Data-Driven Quality and Process Optimization

Once the PMT CMM was fully integrated into Chengxin’s inspection process, the benefits were immediate. The precise measurement data helped engineers identify the root cause of assembly misalignment, optimize machining parameters, and improve process stability.

Beyond the robot turntable, the FUTURE PLUS 1587 has since been applied to other projects, such as MTU main bearing caps, marine cylinder heads, and connecting rods. The consistent accuracy and traceability have strengthened Chengxin’s overall quality control and production efficiency.

Building the Future of Precision Manufacturing

The collaboration between Chengxin Machinery and PMT represents more than a single equipment upgrade—it’s a shift toward data-driven, intelligent manufacturing. With PMT’s advanced CMM technology, Chengxin continues to set higher standards for precision, reliability, and innovation in the machinery industry.

PMT is committed to empowering manufacturers worldwide with high-precision metrology solutions.

Whether you’re optimizing machining processes or ensuring product consistency, PMT helps you measure with confidence and manufacture with precision.

Learn more about PMT’s CMM solutions and discover how we can help your business achieve smarter, more reliable production.

The post Precision That Drives Progress: How PMT CMM Helps Chengxin Machinery Achieve Smart Manufacturing appeared first on PMT Technologies.

]]>The post A Complete Guide to PMT’s Newly Upgraded Technical Service appeared first on PMT Technologies.

]]>

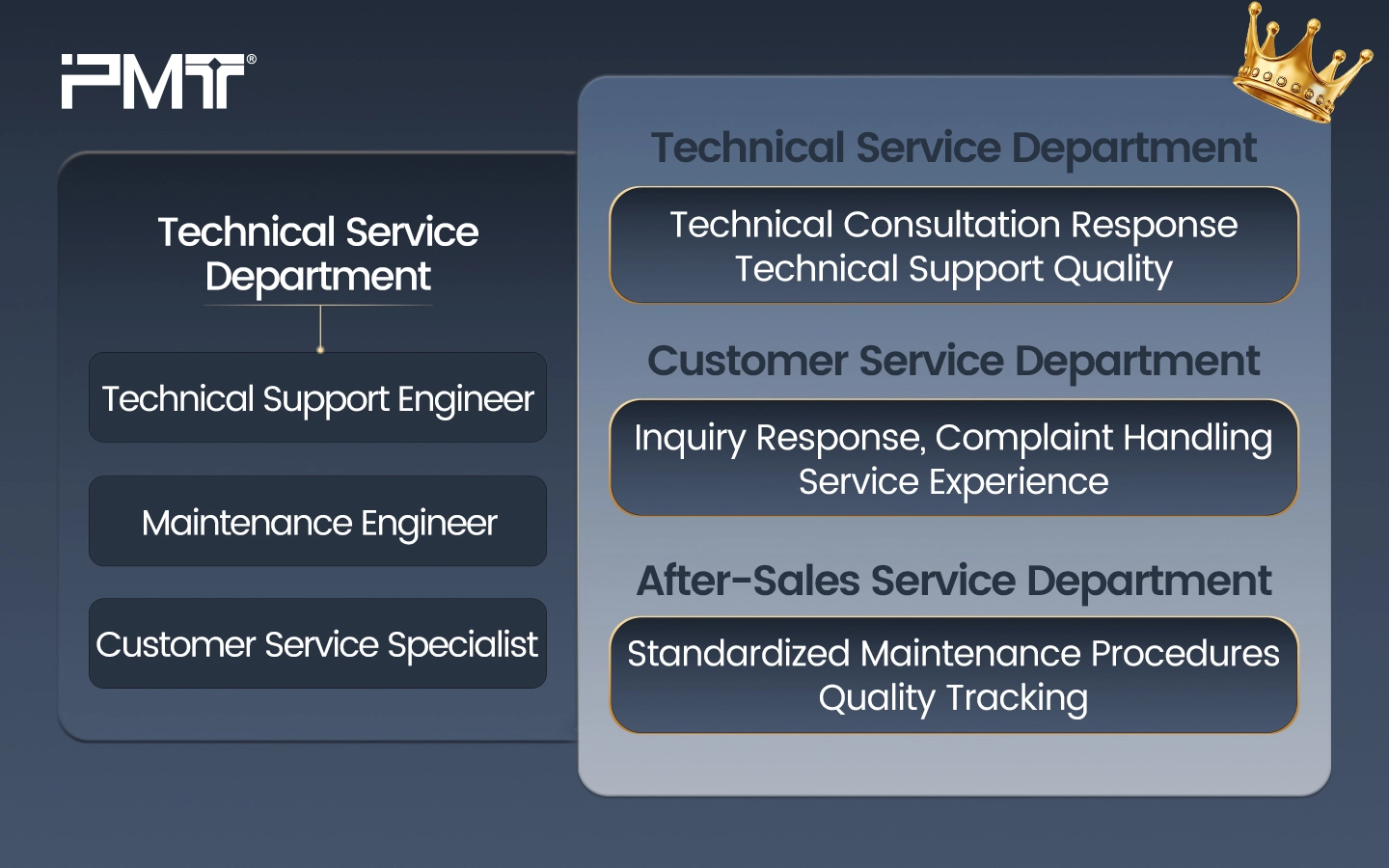

1. From “Problem Solving” to “Problem Prevention”

PMT’s 3D measurement solutions are trusted by leading enterprises across various industries worldwide. By analyzing thousands of cases, we’ve shifted our technical support model from reactive problem-solving to proactive problem prevention. This change minimizes device downtime and maximizes customer satisfaction.

Key Upgrades:

- Service Lifecycle Records: Each PMT device now comes with a complete digital service record, covering delivery, installation, training, maintenance, and repairs. These records are accessible at any time, ensuring full transparency.

- Cross-Department Collaboration: We have integrated technical support, customer service, and maintenance teams to deliver a seamless customer experience, achieving a 100% response rate.

2. A Breakdown of the After-Sales Process

- Technical Follow-Up Support: After training, customers receive an additional 3 months of follow-up support from PMT technical engineers.

- Continuous Support Tracking: After training, we conduct follow-up calls to ensure key concepts are fully understood, reinforce technical skills, and help optimize internal management at our site.

- Diversified Support Channels: PMT offers support via WhatsApp for real-time assistance.

Global: +86-1529 5618 055, Americas: +86-1996 2688 013, Europe: +86-1732 7757 762

Asia-Pacific: +86-1996 2688 013, Africa: +86-1732 7757 762

- Regular Training Course: PMT regularly organizes specialized courses, such as “Advanced 3D Measurement Technology,” to support continuous skill development for international customers and partners.

- Multi-Channel Repair Requests: Customers can submit repair requests through our official website (www.krhmd.cn), email us at info@pmt3d.com, or contact our WhatsApp after-sales hotline at +86 1377 1790 343.

- Emergency Support: For complex issues, our technical team activates an emergency response plan, providing continuous follow-up until the issue is fully resolved.

3. How We Ensure Your Core Needs Are Met?

PMT offers personalized “one-on-one” support channels. Should you encounter any issues, visit www.krhmd.cn to find relevant contact information and submit a message. For suggestions, requests, or collaboration opportunities, please use the “About Us – President’s Mailbox” section on our website. PMT is committed to responding within three working days to ensure your concerns are addressed in full.

The post A Complete Guide to PMT’s Newly Upgraded Technical Service appeared first on PMT Technologies.

]]>The post Portable Cmm | PMT Welcomes Visit from Turkish Partner appeared first on PMT Technologies.

]]>

In-depth Visit

Guided by PMT technical team, our partners visited the cutting-edge production facilities, exhibition hall, and calibration & maintenance room, gaining a comprehensive understanding of PMT’s entire product line from manufacturing to after-sales service.

Technical Exchange

The Bilgino?lu team focused on exploring the core capabilities of PMT’s portable coordinate measuring machine:

? High-precision hardness testing

? Efficient and rapid scanning

? 90° elevated scanning

Valuable Feedback

Mr. Ismail, the CEO of Bilgino?lu remarked, “The high accuracy and stability of PMT’s measuring arm are truly impressive, I’m confident we will deepen our cooperation with PMT.”

PMT remains committed to its core values of “Customer First, Full Commitment and Sustainable Innovation,” continuously striving to provide more precise and intelligent measurement solutions for global customers. Currently, PMT is actively expanding its partnerships and looking forward to collaborating with more partners to advance together in the global industrial precision measurement.

The post Portable Cmm | PMT Welcomes Visit from Turkish Partner appeared first on PMT Technologies.

]]>The post 「Measuring Arm」「CMM」 PMT’s CMMs Shine at the Control Show appeared first on PMT Technologies.

]]>

On May 9, 2025, at the Control Show in Stuttgart, Germany – PMT Technologies unveiled its latest products: the next-generation GAMMA Series PMT measuring arm (featuring the new blue laser scanner and 8-axis rotary worktable), the FUTURE PMT CMM machine, the PRIME PMT coordinate measuring machine, and the PMT Inspect 3D measurement software, marking a new chapter in industrial metrology field.

CMM’s Global? Stage: From China to the World

As one of the world’s largest and most professional measurement instrument exhibitions, Control Show serves as a “bellwether” for industry trends. PMT’s products cover the entire industrial measurement field, from PMT portable coordinate measuring machines (adaptable to diverse environments) to high-precision PMT CMM equipment (micron-level accuracy), and multi-scenario 3D industrial software solutions, captivating international guests.

- Flagship Product: GAMMA PMT Measuring Arm

Debuting at the global exhibition, the PMT GAMMA Series portable CMM machine redefined industry standards. With the world’s first external decoupling and internal balancing system, the GAMMA PMT portable coordinate measuring arm combines precision and portability, enabling effortless operation, high stability, lightweight, and affordable maintenance.

Both 6-axis and 7-axis PMT portable CMM systems can work seamlessly with an 8-axis rotary worktable (full rotational axis), allowing users to perform full scope measurements on workpieces in fixed positions without complex setup. Compared to standard 6-axis and 7-axis systems, the GAMMA portable CMM with an 8-axis rotary worktable not only measures hard-to-reach spots but also increases scanning efficiency by over 40%, greatly reducing inspection time and human error, solidifying PMT’s leadership in precision measurement field.

- Another Highlight: PMT Inspect Measurement Software for CMM

PMT’s self-developed PMT Inspect 3D measurement software, paired with the GAMMA PMT measuring arm, demonstrated real-time capture of precise data in any environment. PMT Inspect ’s core algorithms hold PTB certification from Germany’s National Metrology Institute, ensuring reliability. The PMT Inspect software enables real-time adjustments for dimensional control, while its automated workflows streamline inspection tasks in production process.

Visitors at PMT’s booth had chance to experience the PMT Inspect firsthand. An Italian guest completed 3-step operations – model alignment, automatic comparison, and report generation – in minutes, earning acclaim for the software’s user-friendly functionality.

- Explore More:PMT FUTURE CMM

The FUTURE PMT CMM measurement machine drew significant attention for its excellent industrial design and dynamic performance. PMT representatives engaged with guests to discuss advanced applications, demonstrate high-speed measurement, ultra-precise detection, and full-digitization.

By merging machine vision, contact measurement, and optical scanning, PMT transcends product competition, focusing instead on comprehensive solutions for different measurement scenarios.

- Future Plans for Global Collaboration

PMT’s distributors from Germany, the UK, Italy, the Czech Republic, Belgium, the U.S., Austria, and Mexico gathered together at the show, responding swiftly to global clients and winning mutual trust.

Keith Mills, head of Europe’s authoritative metrology media Metrology News, conducted an in-depth dialogue with PMT founder Tom on the “European Expansion Strategy”, highlighting PMT’s commitment to global collaboration.

CMM and Portable CMM: The Path for Localized Innovation

PMT’s outstanding performance at the Control Show reflects its global strategy: leveraging core technologies to build an integrated worldwide system. As the journey continues from Stuttgart, PMT remains dedicated to adding fresh impetus to strengthen the industrial measurement field.

The post 「Measuring Arm」「CMM」 PMT’s CMMs Shine at the Control Show appeared first on PMT Technologies.

]]>The post PMT Sets a Benchmark in Industry-Education Integration appeared first on PMT Technologies.

]]>

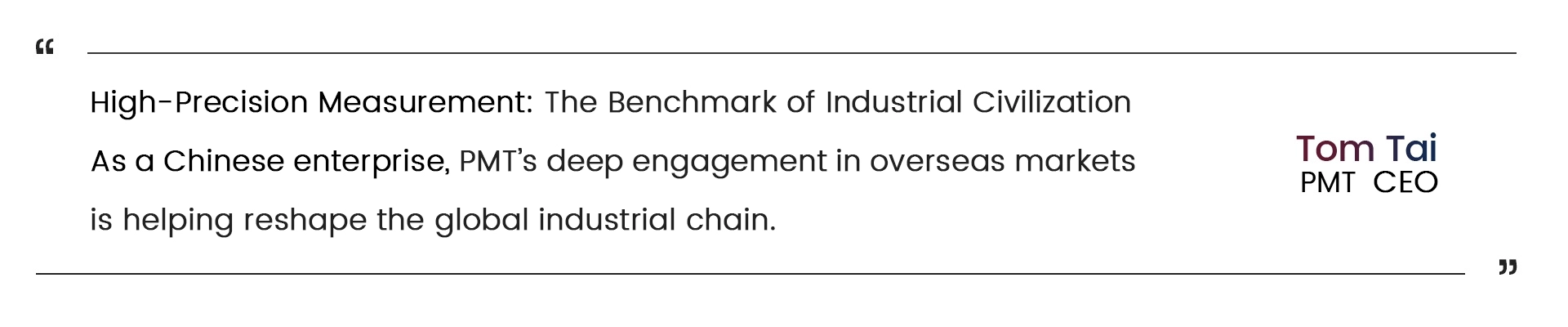

Live Lesson Battles: Where Teaching Meets Competition

The PMT potable coordinate measuring machine has become the star “teaching tool” of the event on accounts of its standout feature of “on-site measurement anytime and anywhere”. Professor Ma from the Mechanical Engineering School highlighted, “As quality inspectors, we must uphold a quality-first mindset to ensure precise measurements.” Students were divided into four teams at random, igniting a hands-on technical competition using the PMT portable CMM.

Practical Challenge: Coaxiality Measurement of Drive Wheel Axles

The event highlighted a key challenge: coaxiality measurement of drive wheel axles. Moving beyond traditional methods, Professor Ma guided students in using PMT’s portable CMM paired with PMT’s self-developed PMT Inspect software. Each team had 30 minutes for hands-on practice, performing GD&T analysis on workpieces by using of PMT portable measuring arm. The PMT Inspect software displayed a remarkable deviation of just 0.01mm—far exceeding the required 0.034mm repeat positioning accuracy. With unmatched efficiency and data reliability, the PMT measuring arm delivered outstanding performance, leaving a lasting impression on all participants.

A Model of Industry-Education Integration: Collaborative Talent Development

PMT’s CMM arms are now widely adopted in top Chinese institutions. To advance the national initiative for precision measurement talent development, PMT is partnering with universities and vocational schools to establish applied colleges and build integrated training platforms—combining high-precision measuring arm with intelligent software solution.

The post PMT Sets a Benchmark in Industry-Education Integration appeared first on PMT Technologies.

]]>The post Explore PMT’s New Gen Solutions at CONTROL 2025 appeared first on PMT Technologies.

]]>-2-1744883690.webp)

Dear Valued Partners & Industry Colleagues,??

We are delighted to announce that PMT will attend the 37th Control, the world’s leading trade fair for quality assurance from?06 to 09 May 2025, in Stuttgart, Germany. PMT will participate in the expo for the third time this year. Under the theme “Precision Manufacturing, High Reliability and Quality Assurance”, PMT will showcase a range of core products with top-notch, high-precision, and high-efficient measurement technologies at this grand event.

Messe Stuttgart

Hall 3 | Booth 3109

06. – 09. May 2025

| ? |

Exhibition Highlights |

|

Portable CMM (Measuring Arm)

Premier Launch of Core Products:you will explore the distinctive advantages of our latest GAMMA Portable Arm and experience the unique charm of portable measurement technology. |

|

|

CMM?(Coordinate Measuring Machine)

Industry-Specific Solutions: PMT Bridge CMM FUTURE & PRIME will be showcased at Control, we will expected On-site technical consultations and customized service plan discussions with you.

|

The post Explore PMT’s New Gen Solutions at CONTROL 2025 appeared first on PMT Technologies.

]]>The post INTERMOLD RECAP | Global Exhibition Facilitates PMT’s Global Business Expansion appeared first on PMT Technologies.

]]>

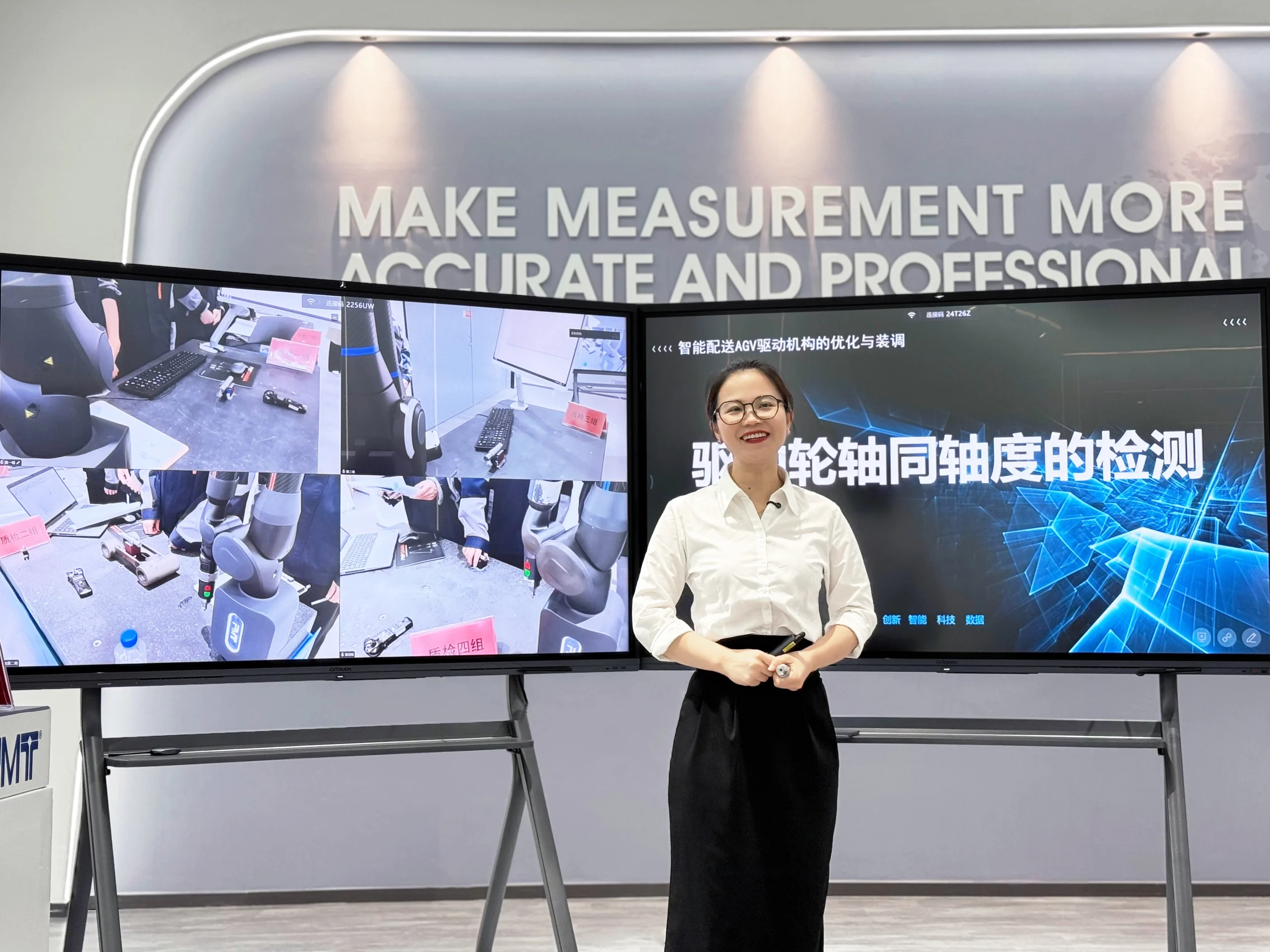

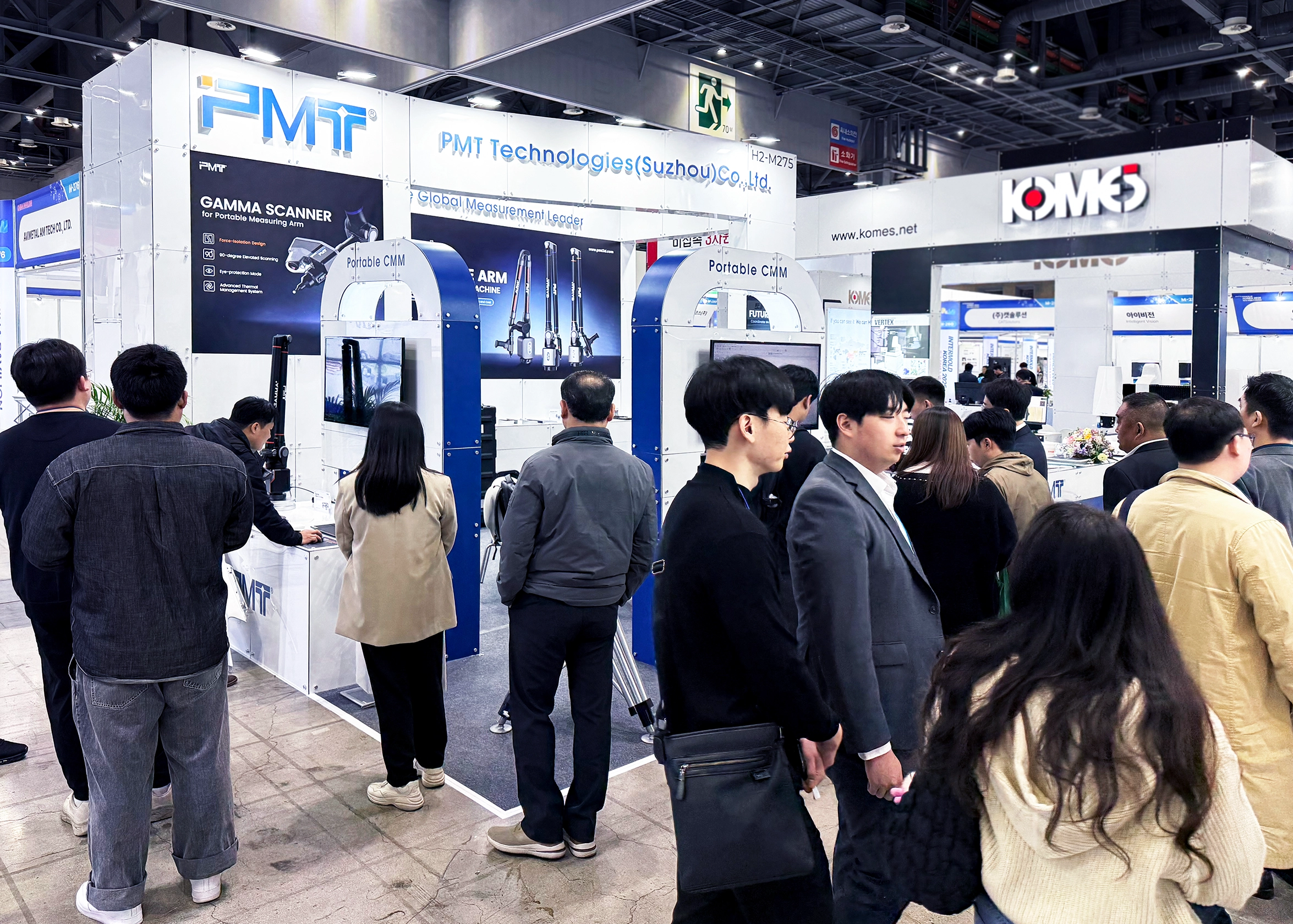

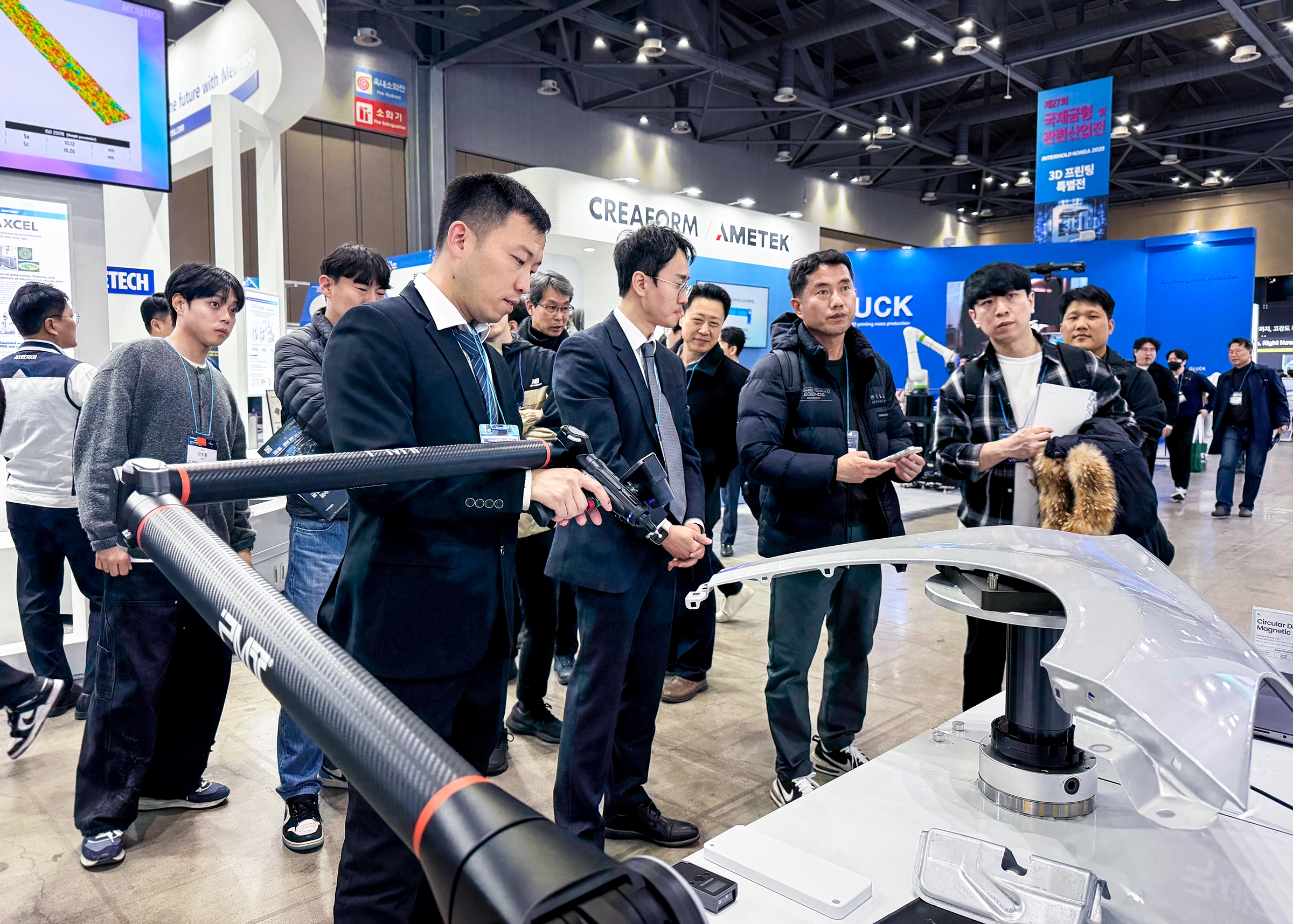

Exhibition in Review

During the event, PMT’s new GAMMA portable CMM made its debut in the Korean market. Featuring a revolutionary external decoupling and internal balancing system, PMT’s articulated arm CMM GAMMA showed its unparalleled performance, captivating international audience at the trade show.

Lim, PMT’s Business Representative in Korea, and Michael, Application Engineer, conducted live demonstrations and technical exchanges at the booth, showcasing the core advantages of the GAMMA portable coordinate measuring machine in high precision, efficiency, and portability. In addition, PMT’s Korean strategic partners came to support actively, having deep discussions with local clients and further solidifying the brand image as well as customer relationships in the region.

The Market is Driven by Innovation.

The showcase of the GAMMA portable measuring arm not only reinforces the leadership of PMT’s technologies in portable measuring arm, but also lays a robust foundation for its business in the Korean market.

Under the vision of committing to technological innovation with concerted efforts, PMT is expanding its global market through international exhibitions, industrial collaboration, talent development, and resource allocation. By accelerating research, development and product upgrade, PMT continues to work with industrial leaders worldwide to make breakthroughs in precision measurement technologies.

The post INTERMOLD RECAP | Global Exhibition Facilitates PMT’s Global Business Expansion appeared first on PMT Technologies.

]]>