The post Portable CMMs in Medical Device Manufacturing appeared first on PMT Technologies.

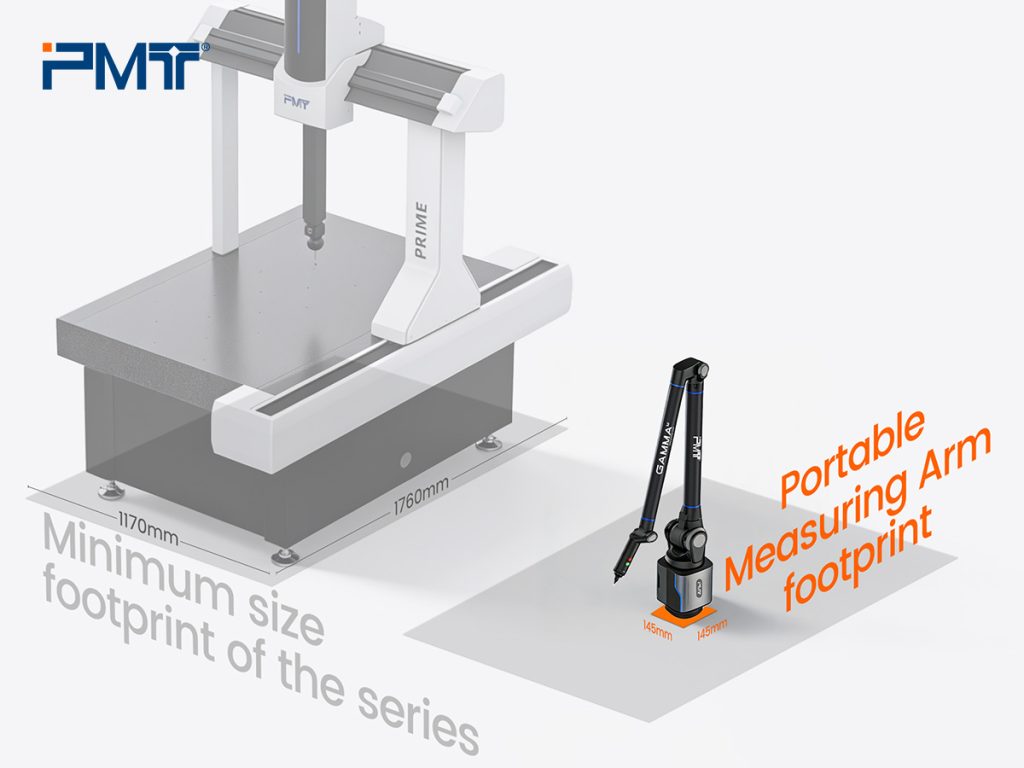

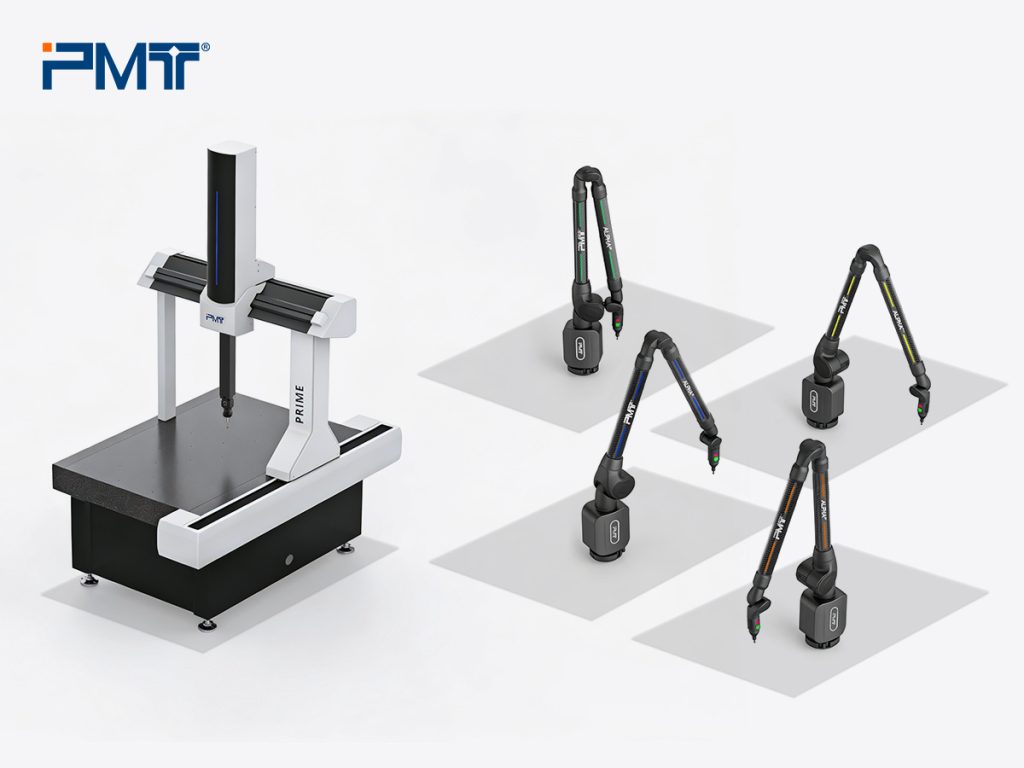

]]>At this point, portable CMMs have become an important technology. Unlike traditional fixed CMMs that require stable temperature-controlled rooms, portable devices offer mobility, ease of use, and the ability to measure directly in production environments. This makes them especially suitable for medical manufacturers seeking consistent quality and faster production cycles.

What Are Portable CMMs? Key Features and Measurement Principles

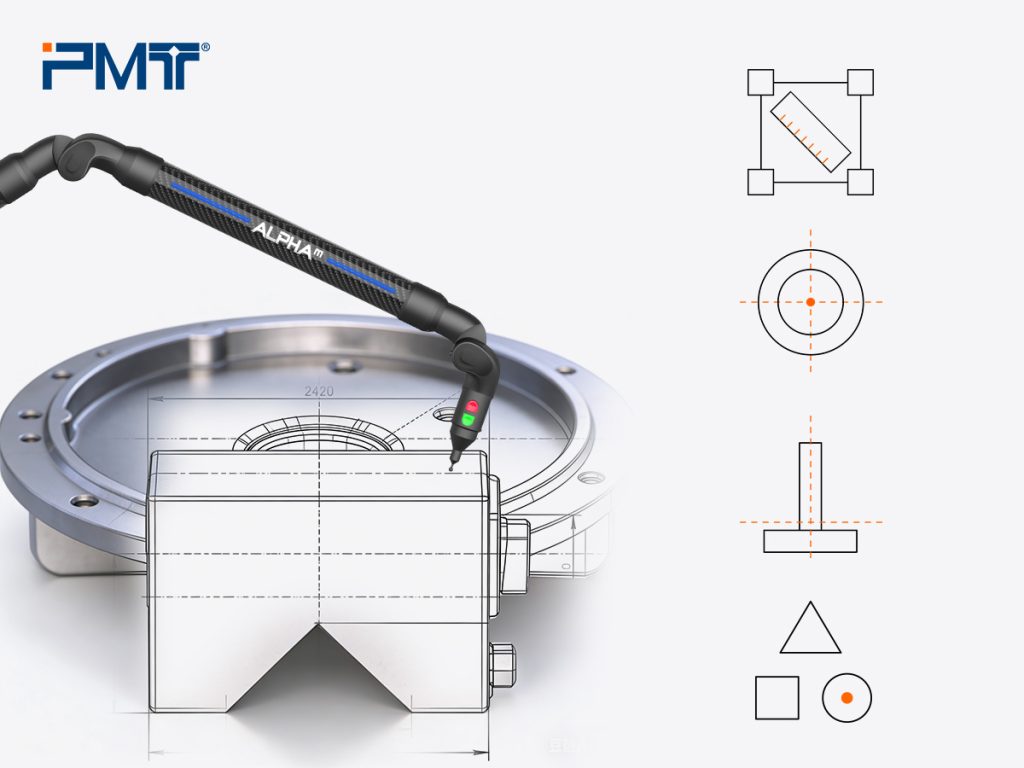

To better understand their value, it is useful to look at what portable CMMs are. A portable CMM is a mobile 3D measuring device, commonly available as a portable measuring arm or paired with a laser scanner. These tools allow operators to capture precise spatial data by touching the surface with a probe or scanning it with a non-contact sensor.

Because portable CMMs do not require a fixed installation or a special measuring room, they can be quickly deployed anywhere on the shop floor. This flexibility reduces downtime, supports multiple workstations, and improves responsiveness during mold validation, part inspection, or product development. In practical medical manufacturing environments, portable measuring arms such as PMT measuring arm?systems are often used to support flexible inspection tasks across different production stages.

Why Portable CMMs Fit Medical Manufacturing Requirements

As medical device manufacturing often involves small batch production, frequent design changes, and strict documentation requirements, portable CMMs align well with these needs. One major advantage is their ability to handle micro-scale components that require precise dimensional control. Whether it is a narrow cavity in a surgical guide or a curved surface on an orthopedic implant, portable CMMs can capture accurate 3D data.

Moreover, the portable CMMs?are not affected by the environment. Their compact structure and easy-to-sanitize surfaces make them suitable for regulated production spaces. The devices also support flexible inspection routines, allowing manufacturers to switch quickly between different product types without resetting a large machine.

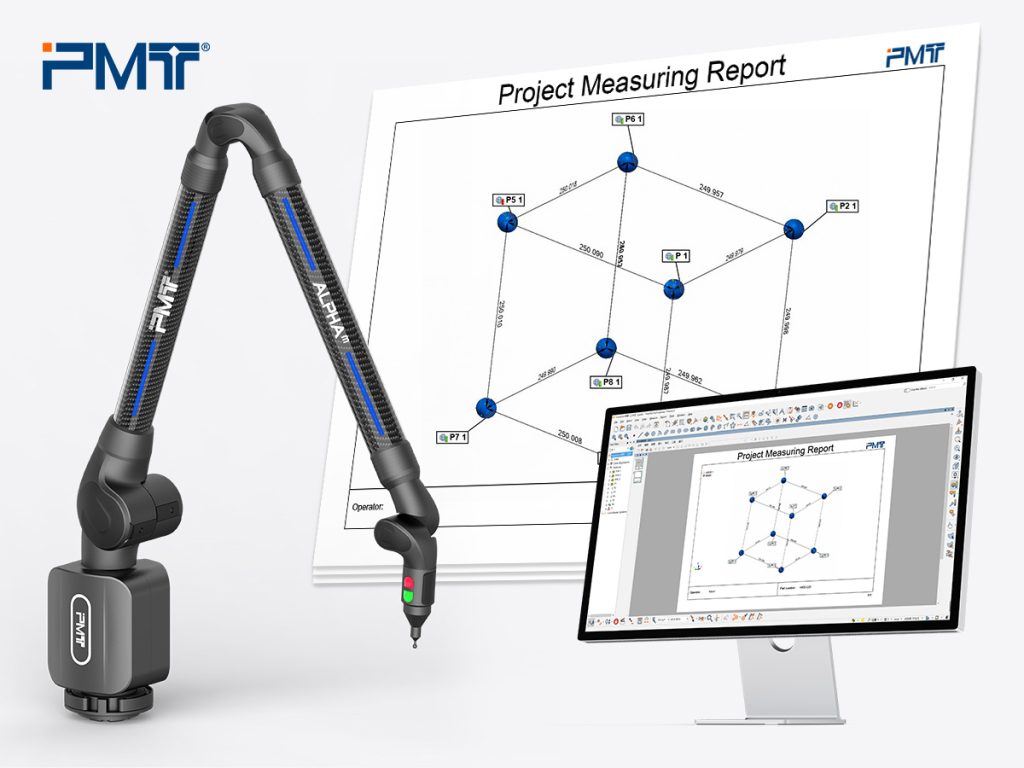

Another reason portable CMMs work well in this field is their strong data traceability. Modern systems store each measurement point, record operator actions, and generate standardized reports that support audits and compliance with international standards such as ISO 13485. For medical companies that must maintain detailed quality records, this documentation capability is critical.

Key Applications of Portable CMMs in Medical Device Production

Because medical device manufacturing includes many different processes, portable CMMs play multiple roles throughout the production chain. For example, in precision mold manufacturing, they help verify core, cavity, inserts, and functional surfaces during machining and assembly. Rapid 3D data collection allows manufacturers to detect dimensional deviations early and reduce the risk of rework.

In practice, portable measuring arms like the PMT measuring arm allow engineers to access narrow cavities, deep holes, and complex freeform surfaces commonly found in medical molds and implant components. This capability is particularly valuable when traditional fixed CMMs or manual gauges cannot easily reach hidden features.

Portable CMMs are also widely used in orthopedic implant production. Since hip joints, knee components, and spinal implants have complex freeform surfaces, laser scanning can capture high-density point clouds for accurate comparison with CAD models.

For minimally invasive surgical tools or dental components, portable CMMs help inspect small geometries that require tight tolerances. Their non-contact measurement capability also avoids damage to delicate surfaces.

In addition, during product development and prototype testing, portable CMMs shorten the iteration cycle. Engineers can quickly verify design changes, perform fit-and-function analysis, and reduce delays between prototype versions.

Portable CMMs vs Traditional CMMs: A Practical Comparison

Although both types of CMMs provide precision measurement, their strengths differ. Portable CMMs offer mobility and ease of use, making them ideal for workshop inspection, mold validation, and real-time analysis. They allow operators to measure large parts or assembled products without moving them to a fixed room.

Traditional CMMs, on the other hand, deliver ultra-high accuracy under strictly controlled conditions. However, they require dedicated space, stable temperature, and trained operators, making them less convenient for flexible medical production environments.

When comparing cost, portable CMMs generally require lower investment in infrastructure. They do not rely on a fixed machine room and can serve multiple production lines. Their adaptable measurement range also supports wide product variation—an advantage in medical manufacturing where each project may differ in size or complexity.

Overall, portable CMMs provide a balance between precision, flexibility, and cost-effectiveness that matches the needs of modern medical plants.

How Portable CMMs Improve Quality Control and Workflow Efficiency

Beyond flexibility, portable CMMs significantly enhance quality control. Laser scanning systems can generate dense point clouds that allow engineers to compare surfaces with the original CAD model within seconds. This helps identify deviations in dimensions, roundness, flatness, or contour shape.

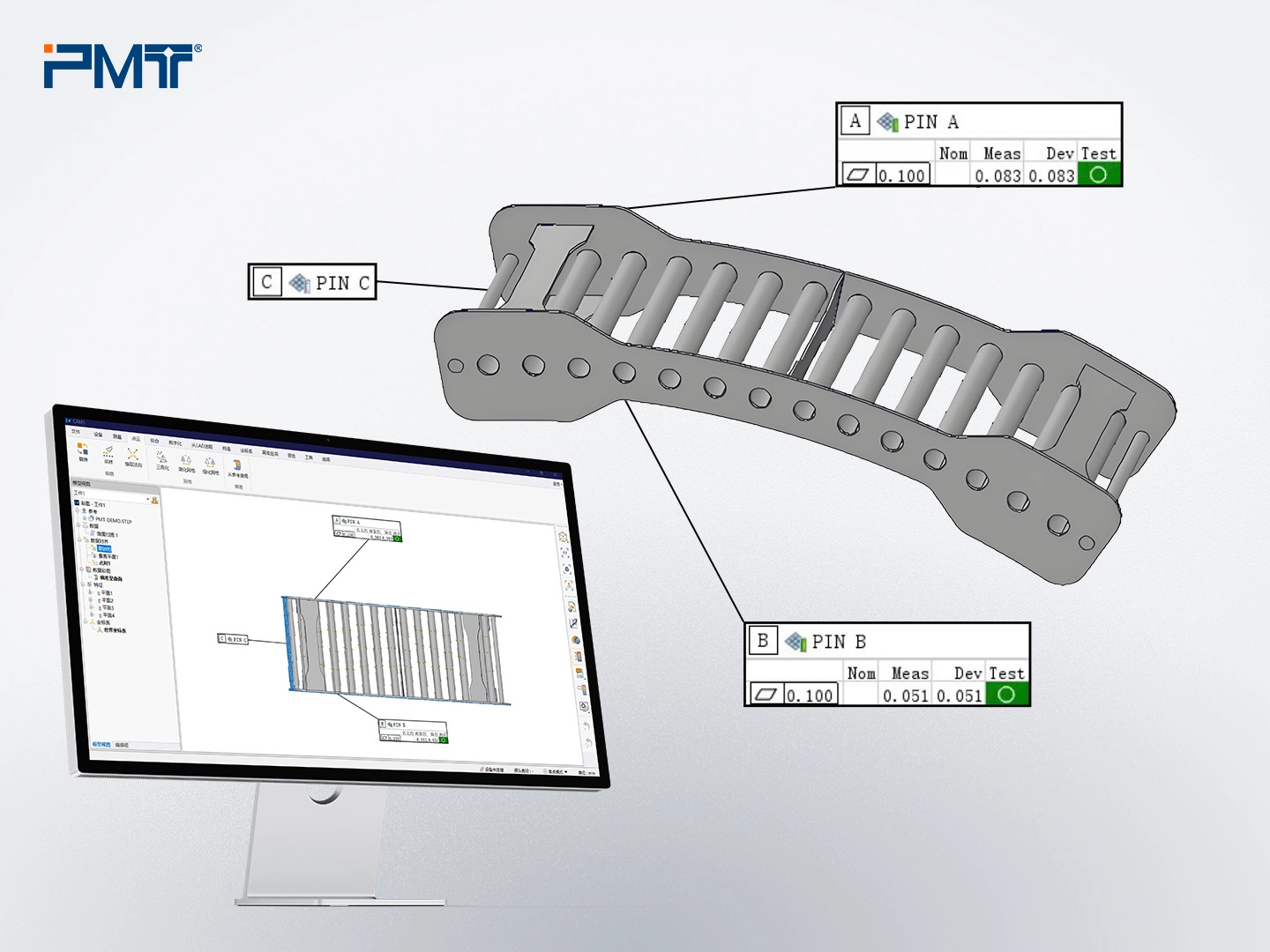

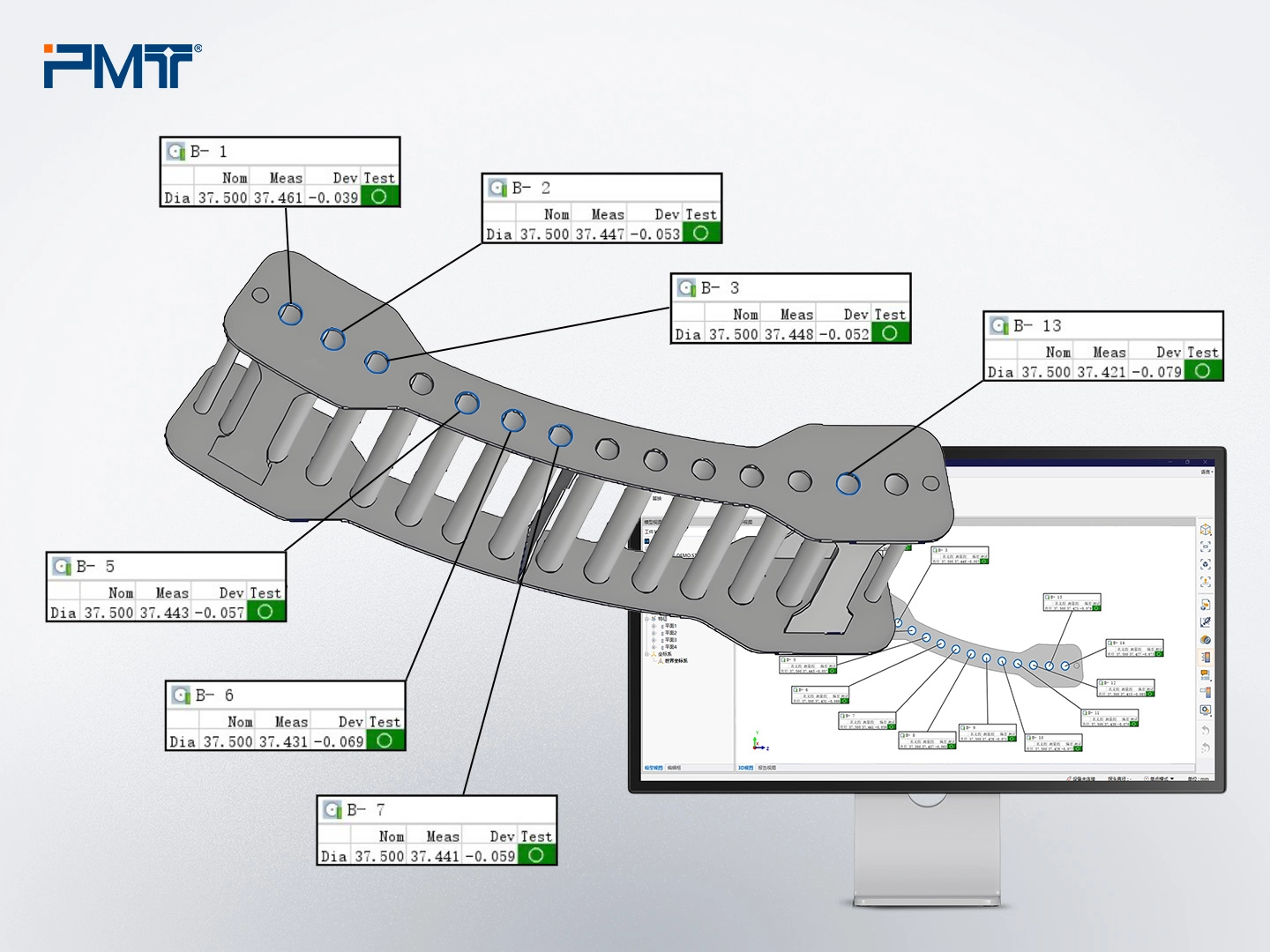

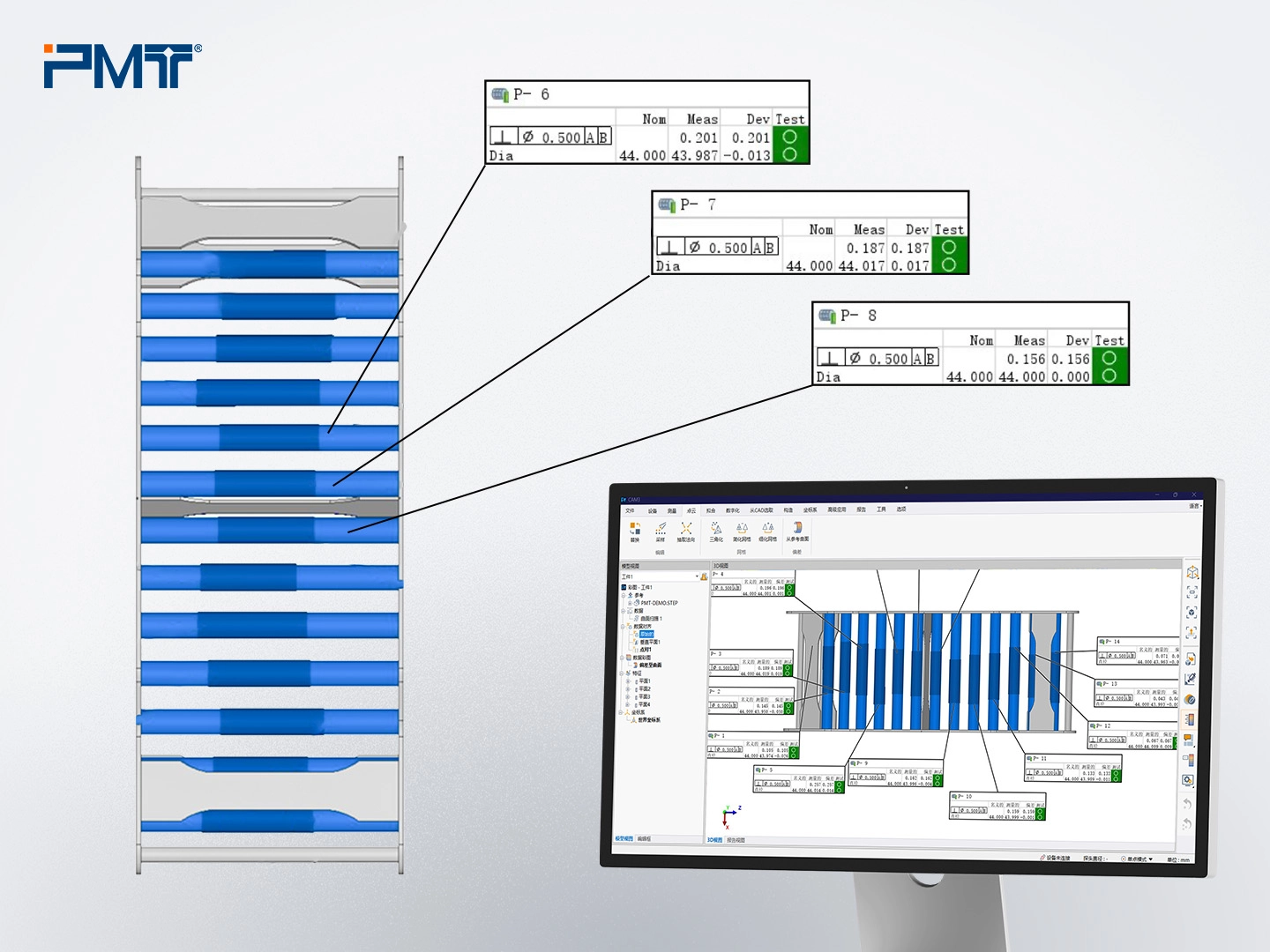

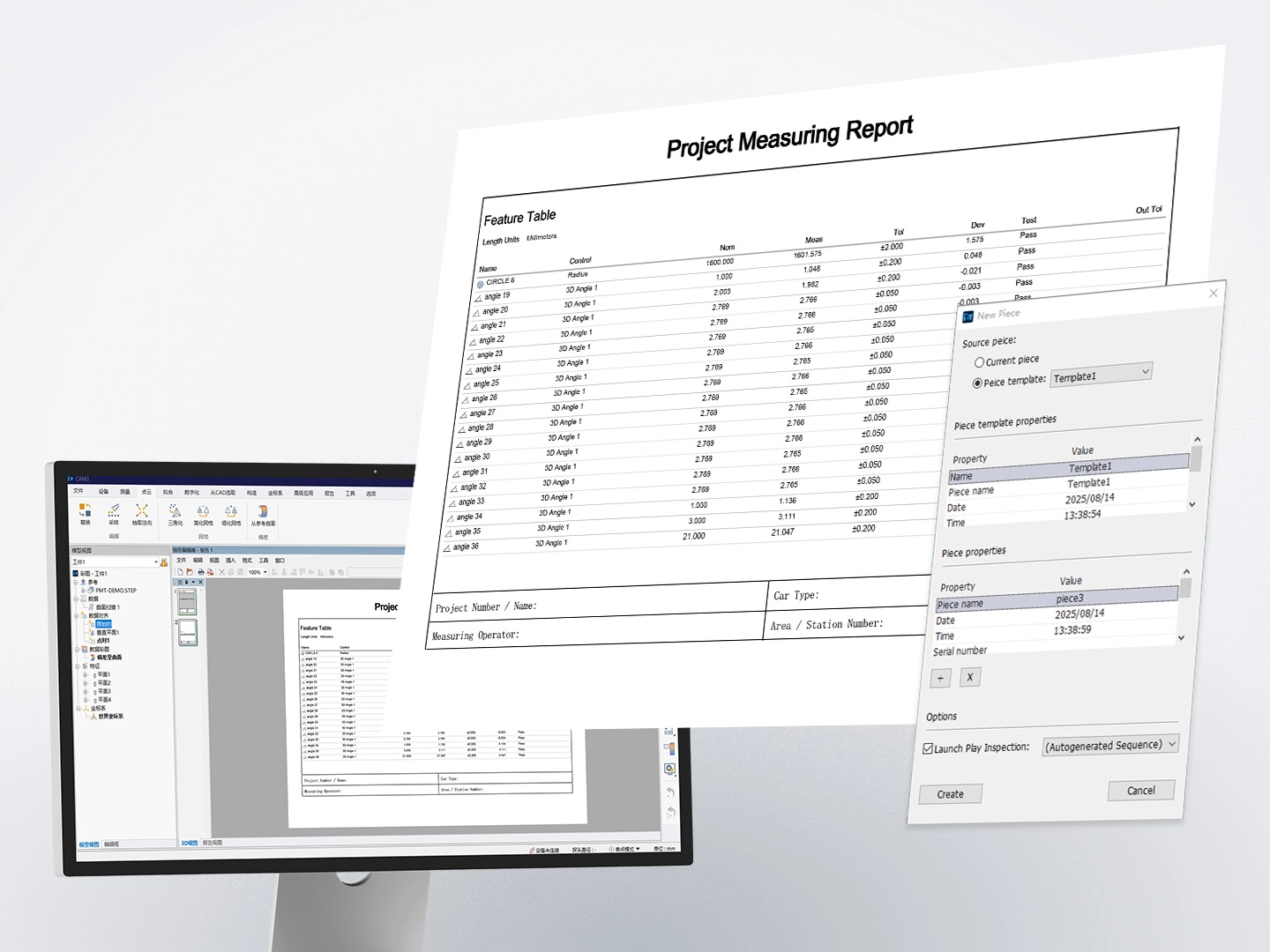

Additionally, portable CMMs support a complete digital workflow. From measurement collection to data analysis and reporting, every step can be automated or standardized. For example, PMT measuring arm systems combined with inspection software enable fast data acquisition, CAD comparison, and standardized report generation directly on the shop floor, reducing reliance on external metrology labs.

By supporting on-site verification and fast measurement cycles, portable CMMs also shorten production lead times. Operators can measure molds immediately after machining, check assembly accuracy on the line, or validate final parts before packaging—without sending them to a metrology lab. This improves response time and reduces overall manufacturing costs.

Choosing the Right Portable CMM for Medical Manufacturing

Because each medical manufacturer has different workflows and product types, selecting the right portable CMM requires considering several factors. First, the measurement range should match the size of the workpieces, whether they are small surgical tools or larger orthopedic molds. Second, accuracy and repeatability must meet industry requirements.

Manufacturers should also consider whether they need probe-based measurement, laser scanning, or a hybrid solution. Probe systems are suitable for high-accuracy single-point measurements, while scanning is ideal for complex surfaces and full-shape analysis.

Software capability is another key factor. A strong platform should support GD&T analysis, generate automatic reports, handle CAD data, and offer stable data management functions. Many manufacturers evaluate portable measuring arms, such as PMT measuring arm solutions, based on software compatibility, accuracy stability, and long-term technical support, especially in regulated medical environments.

Conclusion: Portable CMMs as a Catalyst for Quality and Compliance

In summary, portable CMMs have become an essential tool in medical device manufacturing. Their ability to deliver precise measurements, adapt to flexible workflows, and support regulatory requirements helps manufacturers improve efficiency and maintain consistent product quality. As the industry continues to evolve toward greater customization and faster development cycles, portable CMM technology will continue to play a central role in supporting accurate, reliable, and compliant production processes.

If you are looking for a trusted portable CMMs supplier, PMT provides high-quality measurement solutions designed for demanding medical applications. Contact PMT to learn how portable CMMs can enhance your inspection efficiency and product quality.

The post Portable CMMs in Medical Device Manufacturing appeared first on PMT Technologies.

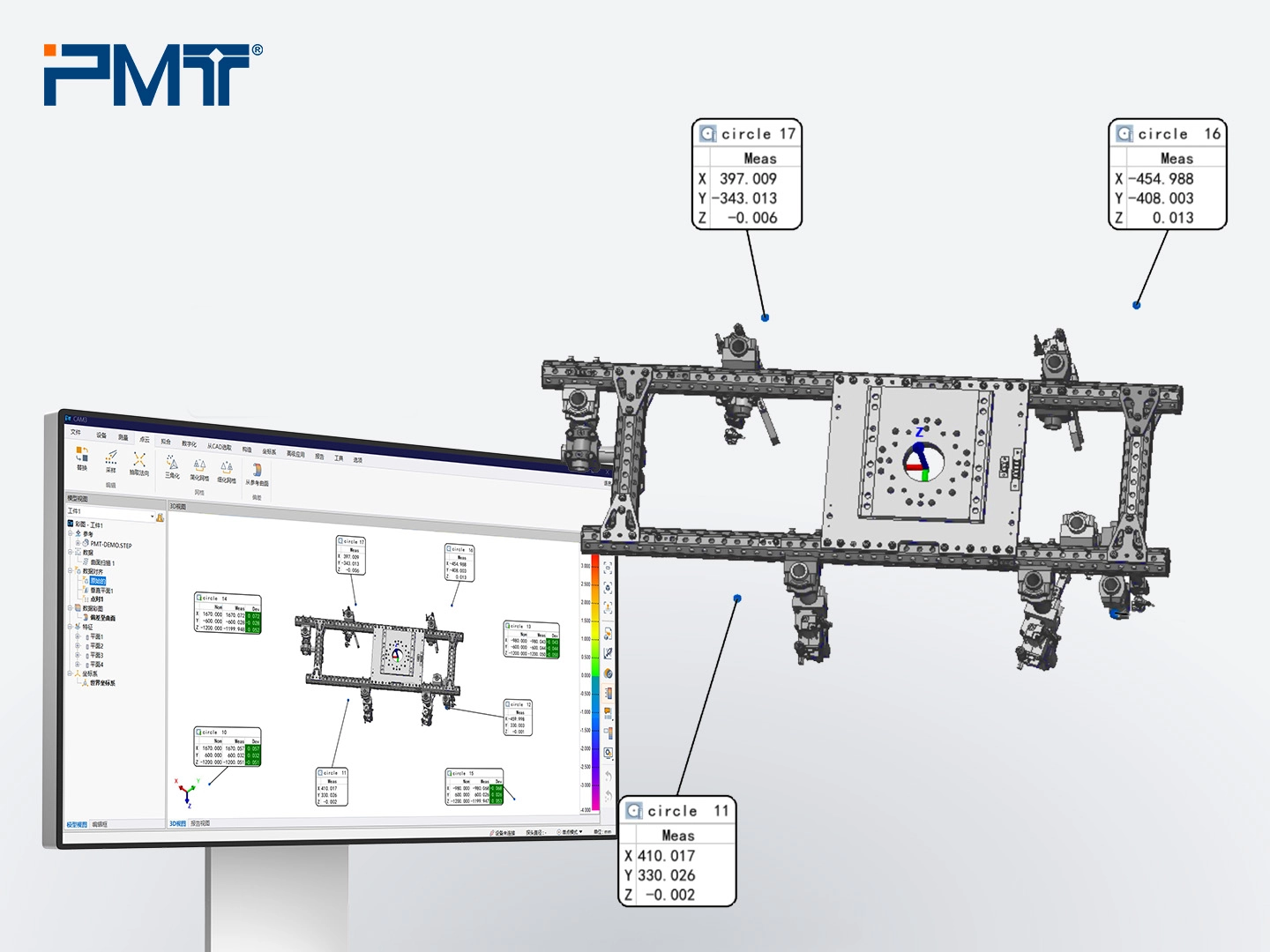

]]>The post Ultimate Guide: How to Use Leapfrog with Measuring Arm for Large Parts appeared first on PMT Technologies.

]]>

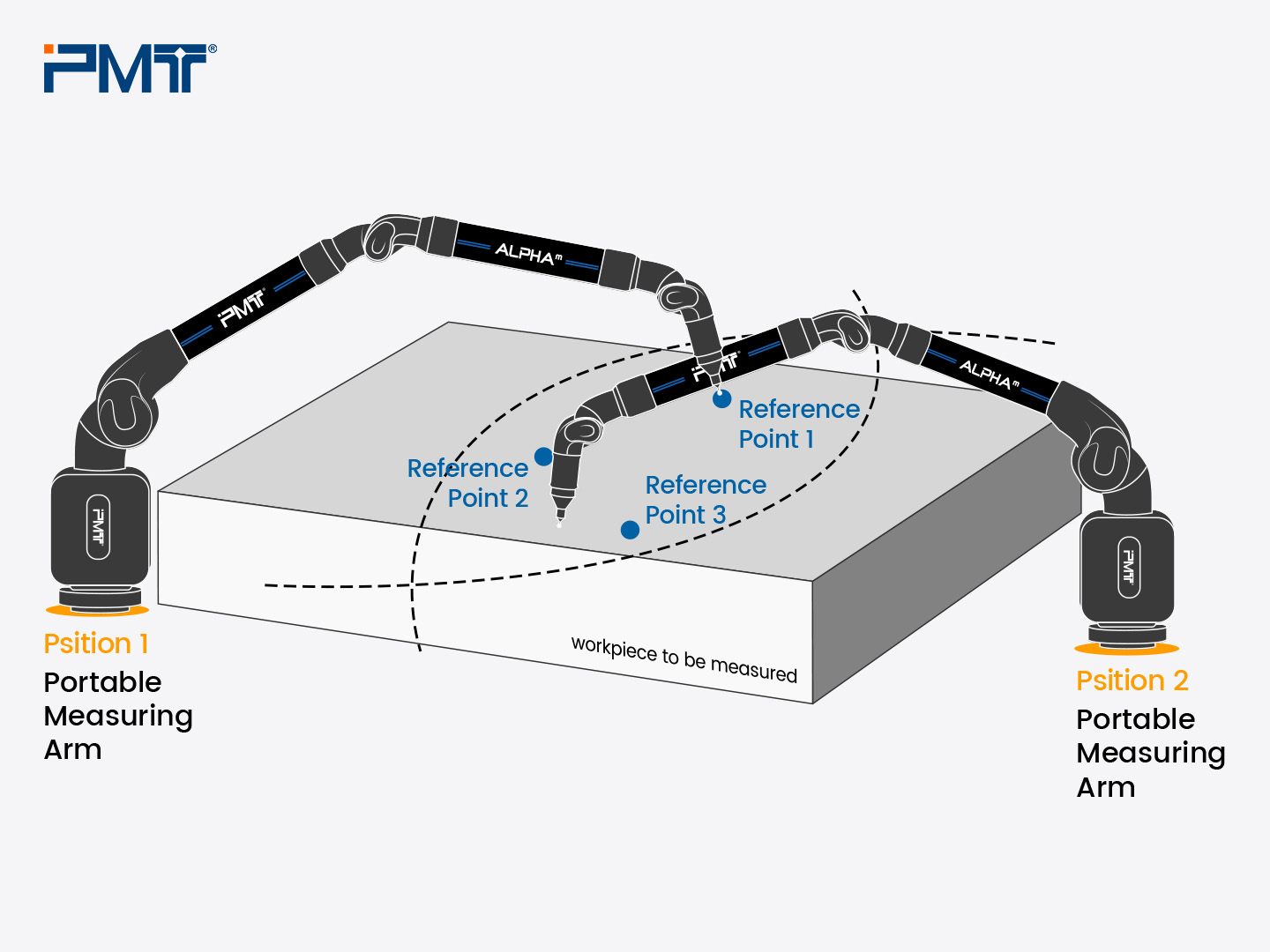

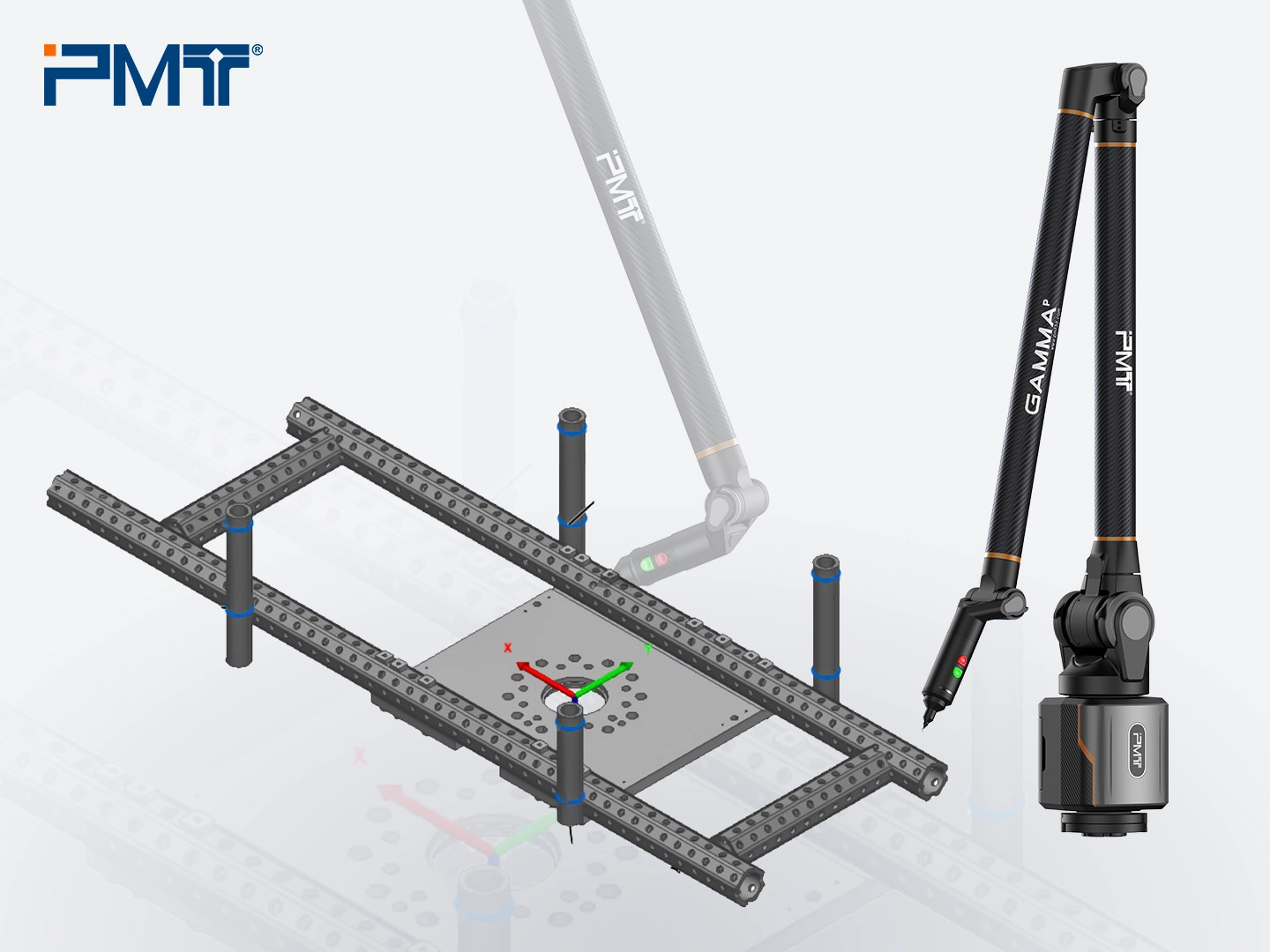

What Is Leapfrog?

- A part moves during measurement, requiring data correlation before and after the move.

- A part exceeds the machine’s range, requiring segmented measurement.

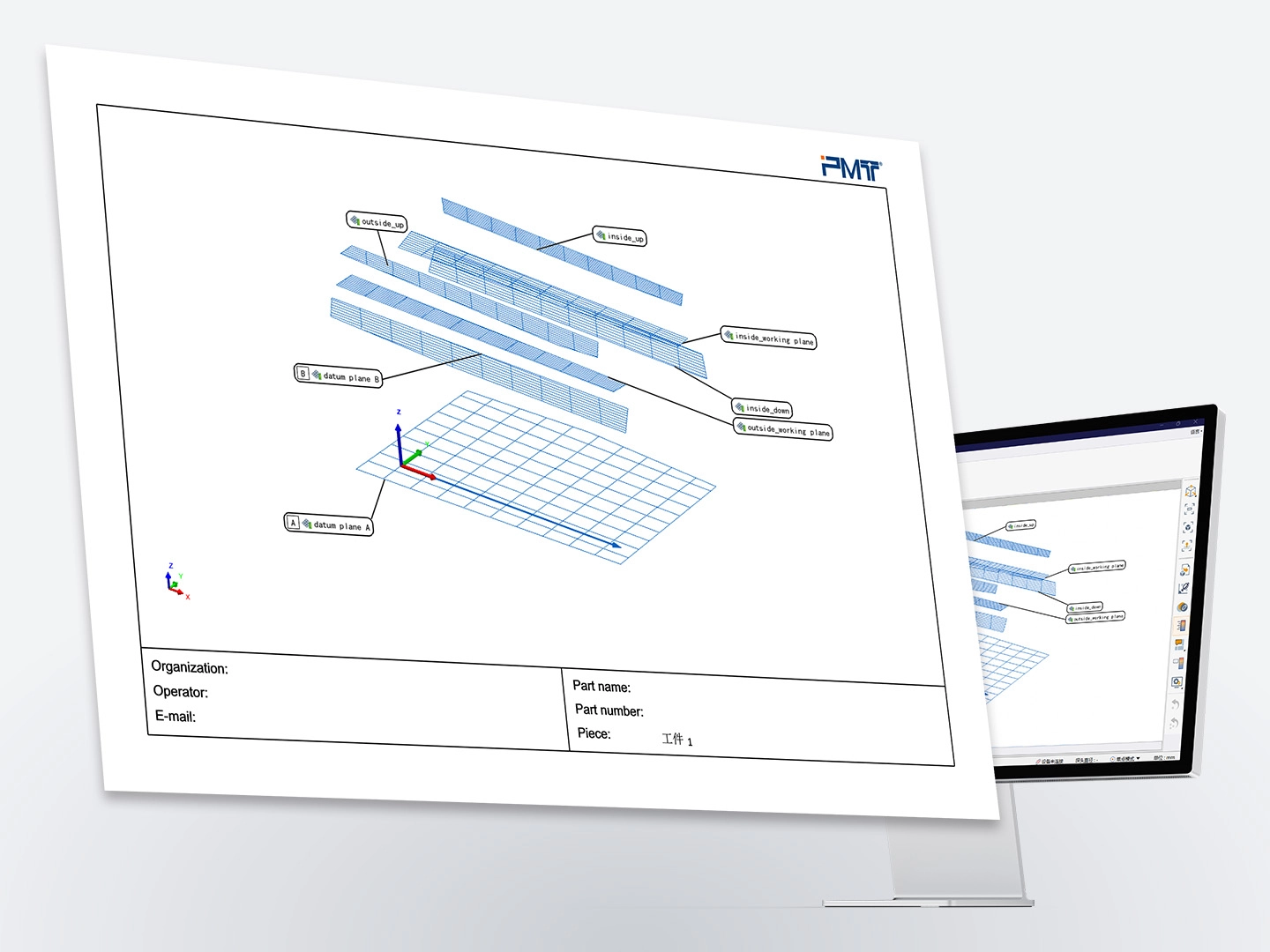

By using leapfrog, you can effectively extend the working volume of the measuring arm. The arm is relocated between measurement positions, and the data is integrated into one unified coordinate system, which ensures seamless, accurate measurements across multiple positions.

How Does Leapfrog Work?

The measuring arm offers great flexibility, enabling measurement in narrow spaces and making it ideal for on-site applications and mass production verification. When combined with leapfrog, the portable arm becomes even more versatile, expanding its operability.

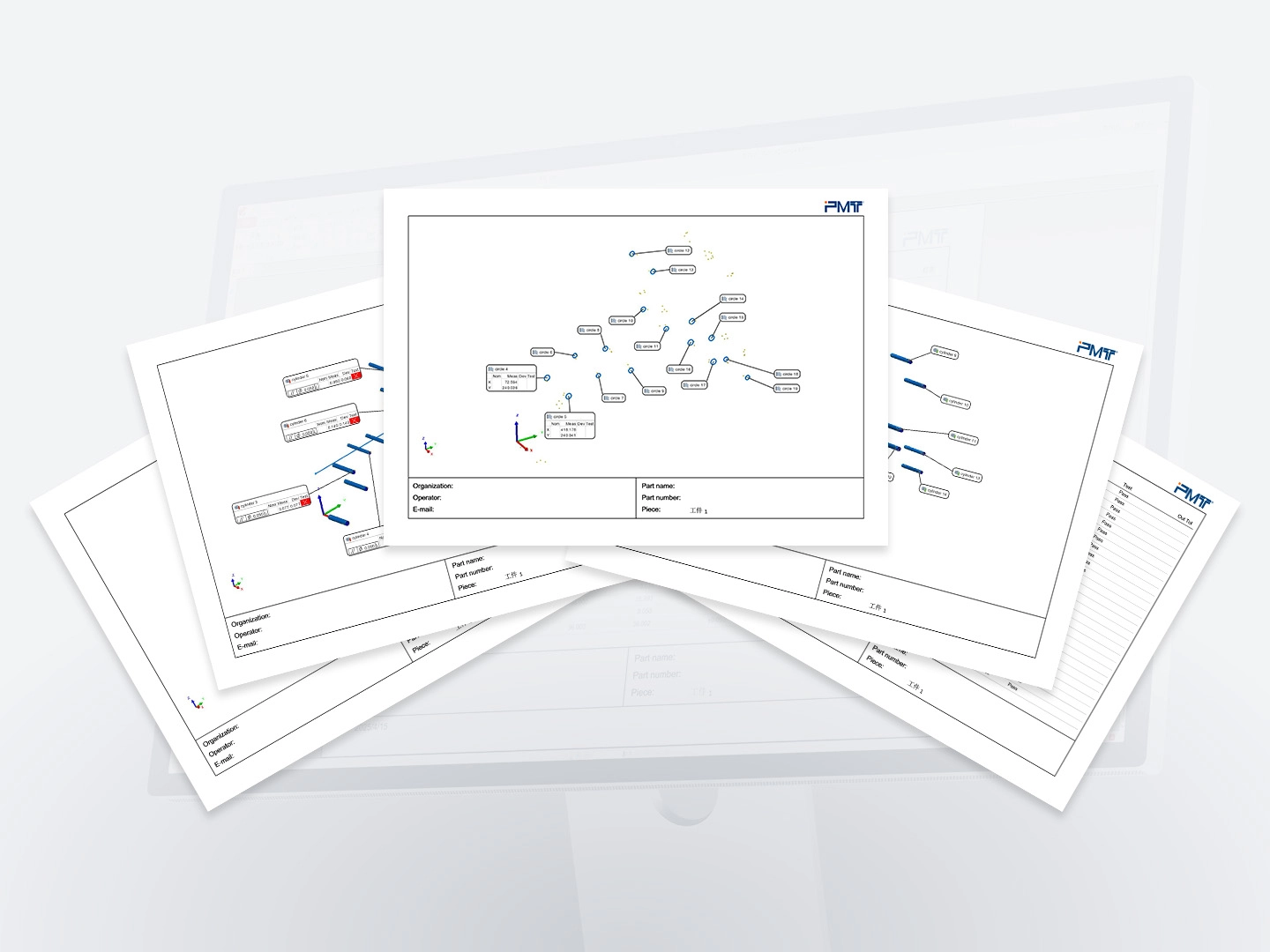

Typical applications include:

- Measuring large molds across different regions.

- Outer contour and assembly measurements of vehicle body structures.

- Inspection of large equipment that cannot be moved during online production.

- Measuring aircraft fuselages and tight spots within equipment.

Step-by-Step: How to Perform Leapfrog Measurement

I. Preparation: Setting Up Reference Points

- Mensurability: Points must be measurable from both initial and subsequent positions.

- Dispersibility: Points should be evenly distributed.

- High Precision: Choose points corresponding to high-precision features (e.g., holes, spheres).

- Rigidity: Ensure that cones are firmly fixed.

B. Secure the measuring arm at Position 1.

II. Formal Leapfrog Procedure

A. Initial Leapfrog

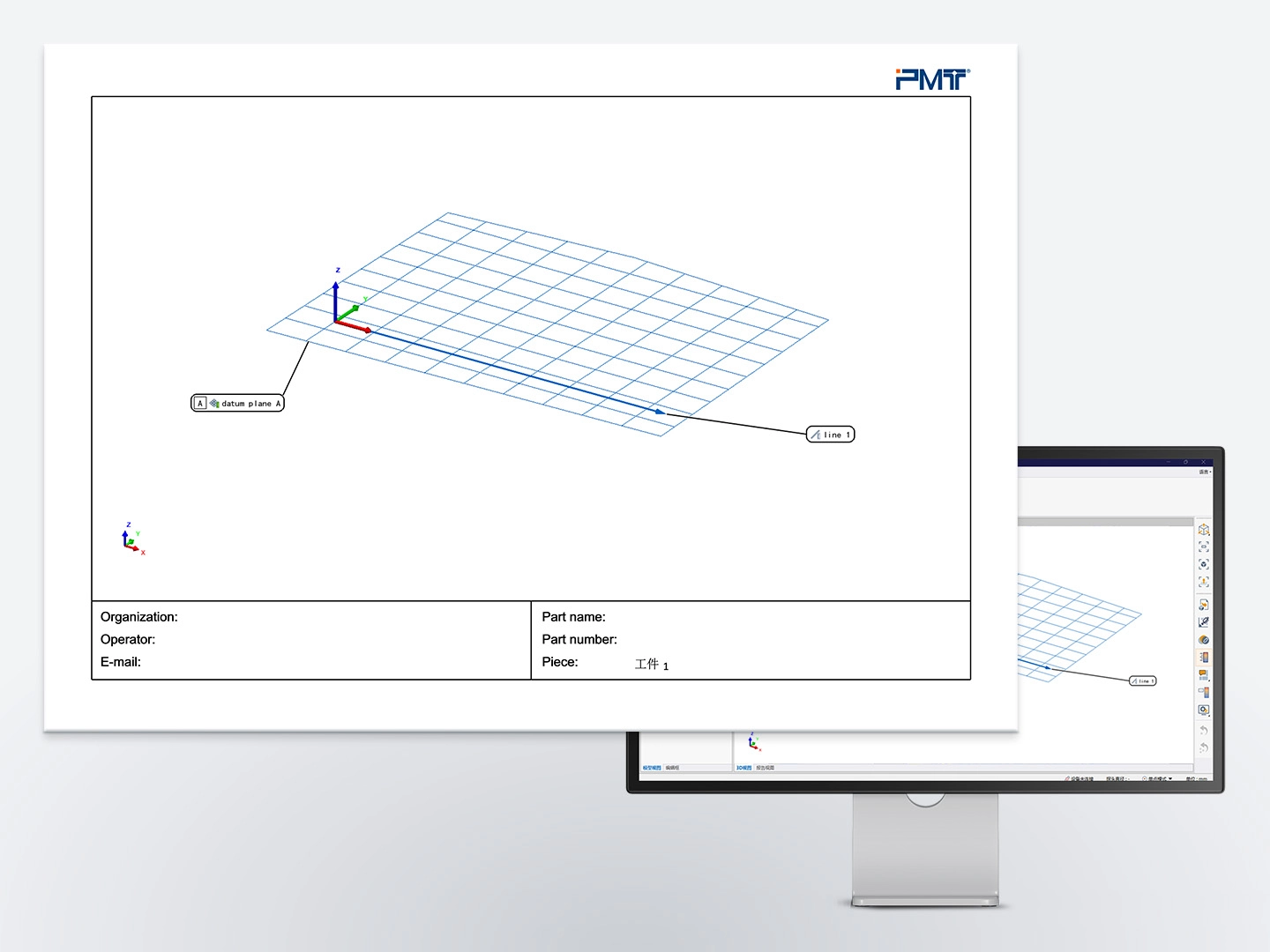

a. Establish the Coordinate System

Using Position 1 as the origin to establish the coordinate system.

b. Feature Capture

Probe all required features at Position 1.

c. Define Position Target

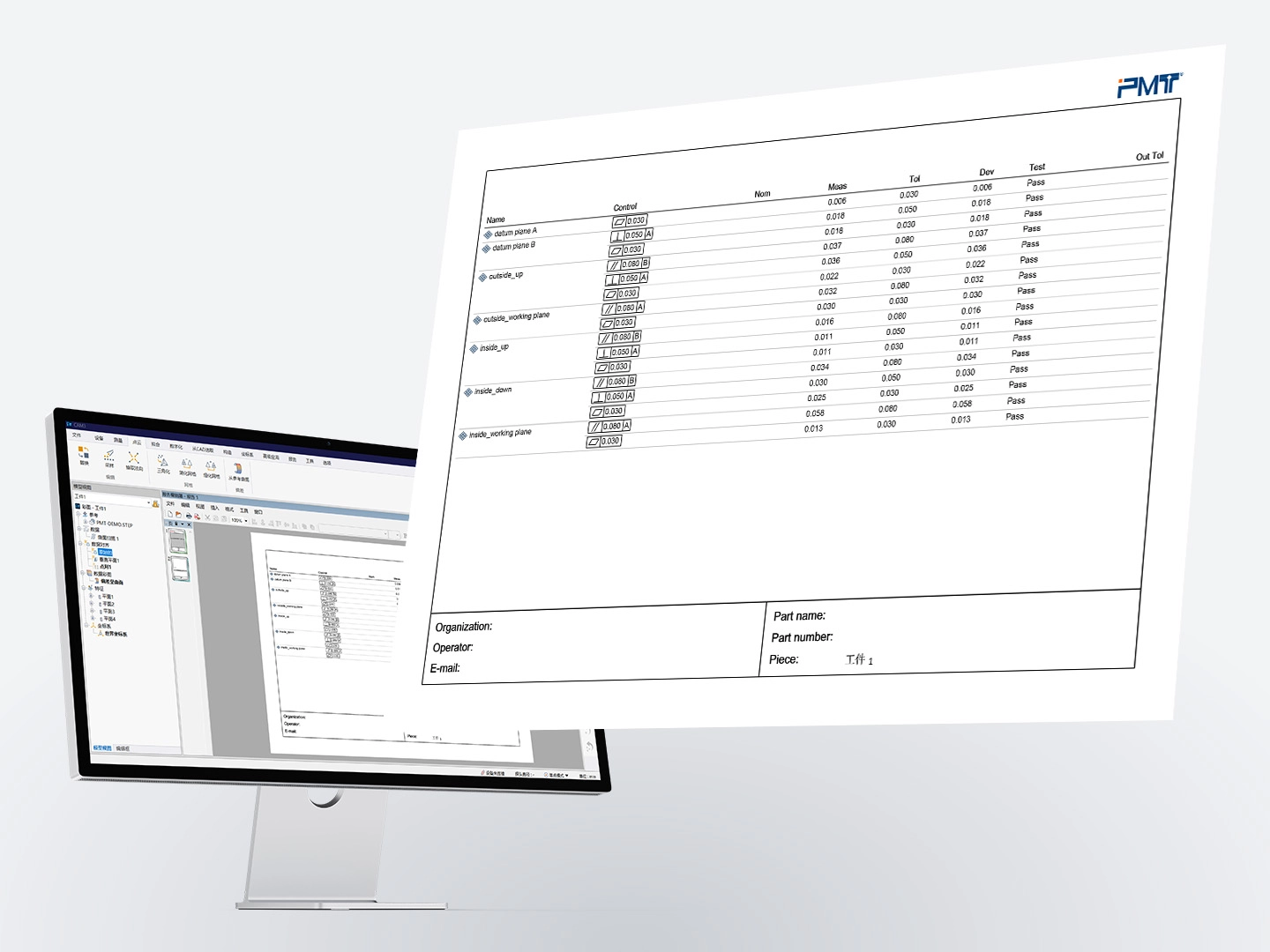

In the software, select “Define Measured Device Position Targets”, then probe Points 1-3. Click “Move Device” to relocate the arm to Position 2 and re-probe the points. The software calculates the leapfrog deviations.

d. Re-check Features

Re-check the features measured at Position 1 and 2. Verify that the feature deviations align with the leapfrog deviations, and perform a GD&T analysis of the features within the Position 2 range. If combined measurements between Position 1 and Position 2 are required, leapfrog can easily facilitate this.

B. Multiple Leapfrog Operations

If a single leapfrog does not capture all required features, such as checking distance or parallelism, repeat the process as needed until all features are measured and the entire part has been inspected.

Why Choose Leapfrog?

- Extended Measurement Range: Allows you to measure larger parts beyond the normal reach of the measuring arm.

- Increased Efficiency: No need for redefining the coordinate system, speeding up the measurement process.

- High Flexibility: Ideal for confined spaces, complex parts, and on-site inspections.

- Cost Savings: Solves range limitations, reducing production costs while maintaining high accuracy.

Conclusion: Using Leapfrog for Efficient Large-Scale Measurements

Leapfrog technology enables portable measuring arms to gather data from multiple positions, enabling “small arm, large part” measurements. While slight accuracy loss may occur, careful planning—taking into account workpiece size, precision requirements, environment, and leapfrog frequency—can minimize errors. By integrating leapfrog with portable arms, enterprises gain an efficient solution for large-scale part measurements, optimizing both precision and workflow.

The post Ultimate Guide: How to Use Leapfrog with Measuring Arm for Large Parts appeared first on PMT Technologies.

]]>The post PMT Showcases Portable Measurement Solutions at AIMC 2025 appeared first on PMT Technologies.

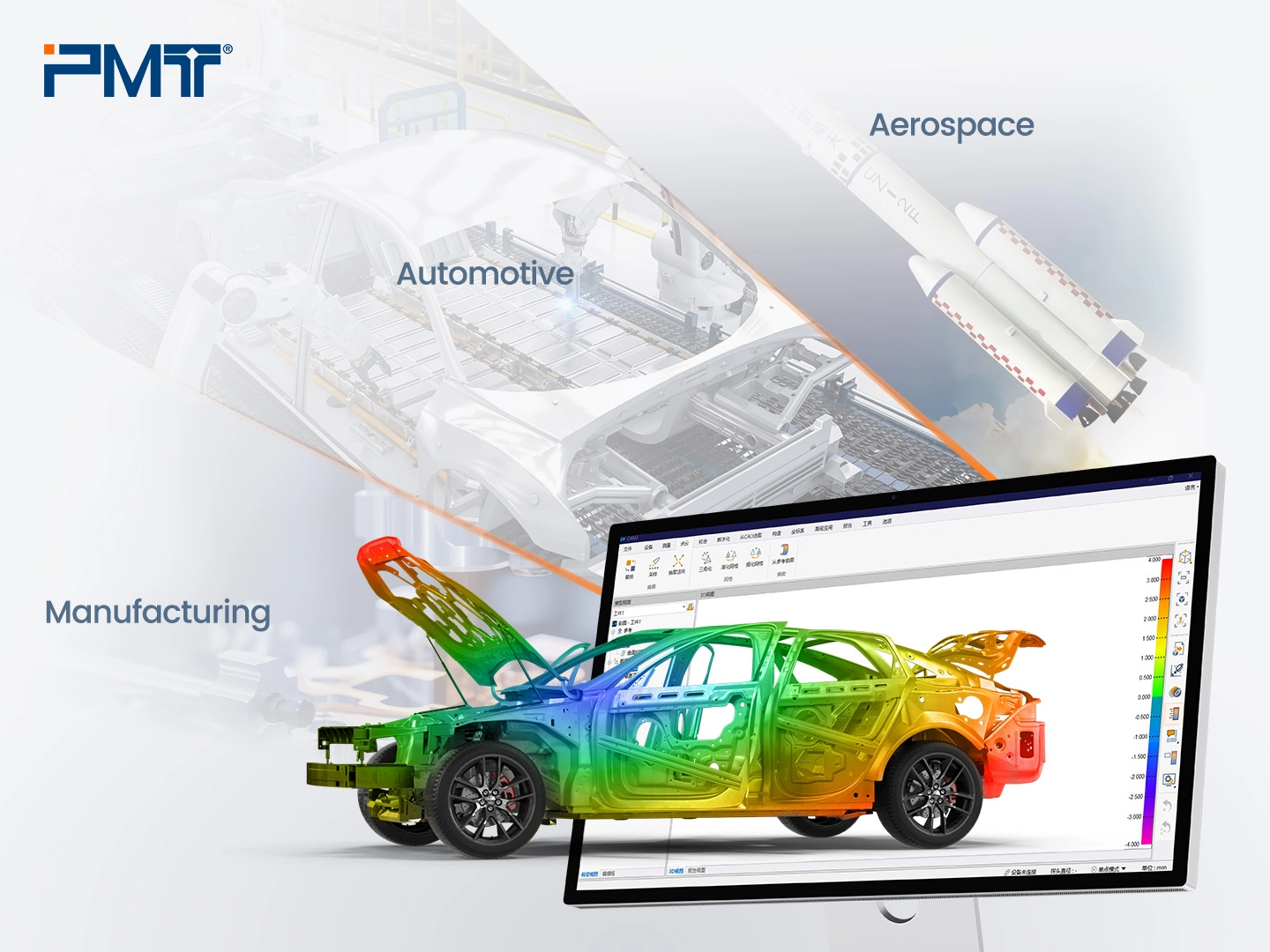

]]>On November 30, 2025, the Aerospace Equipment Intelligent Manufacturing Innovation and Development Conference (AIMC) wrapped up in Shandong province, hosted by the People’s Government of Fushan District, Yantai City, and Nanjing University of Aeronautics and Astronautics. With the theme “Intelligent Manufacturing Leads the Future of Aerospace,” the conference attracted over 350 experts, academics, and enterprises, with PMT invited as a key player in high-precision 3D measurement technologies.

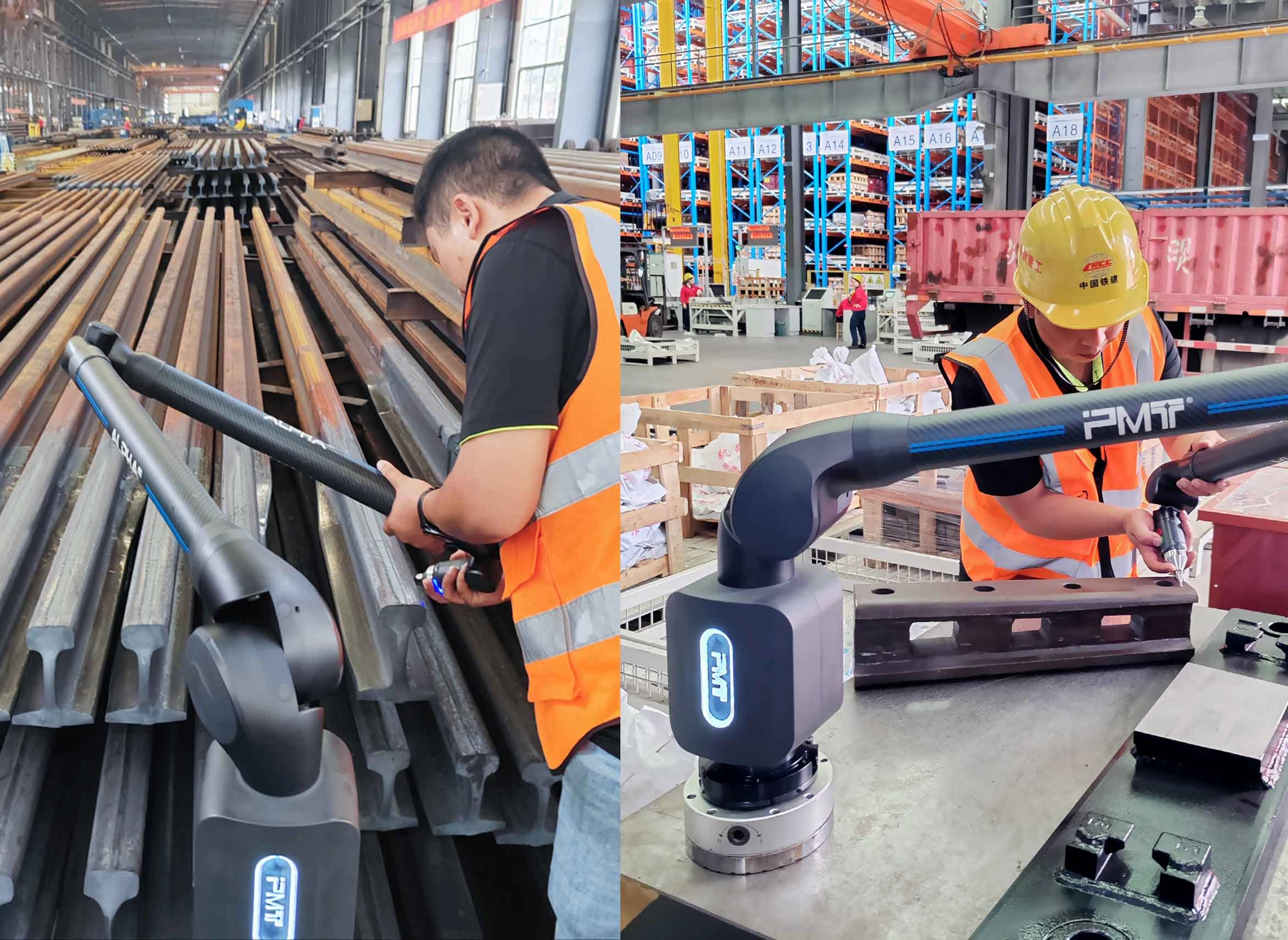

Live Demos Highlight the Power of Measuring Arms

In the technical exhibition zone, PMT conducted dynamic on-site demonstrations, showcasing the core capability of its portable measuring arm solutions: performing accurate measurement anytime, anywhere.

The demonstration featured the scanning and inspection of typical aerospace components. It clearly displayed the outstanding performance of PMT’s blue light scanners integrated with the GAMMA and ALPHA measuring arms. These portable arms excel in high precision, high efficiency, and true portability. What’s more, PMT’s Portable CMM Arm solution is capable of capturing complex surfaces, comparing inspection data with CAD models in real-time, and generating reports rapidly. The versatility of the PMT Arm was also highlighted by its detachable 3D scanners, which enhance measurement accuracy and broaden the scope of inspections across various aerospace applications.

PMT’s Technological Leadership Sparks Industry Dialogue

During the event, PMT’s booth attracted a continuous stream of visiting experts. Mr. Chen Zhonggui, Researcher at the China Academy of Space Technology and Chief Designer of the Beidou-3 satellite, held an in-depth and productive discussion with PMT’s Founder and CEO, Tom Tai. They explored specific measurement challenges in aerospace quality control, first-article inspection, and other areas. PMT’s independent technological capabilities in providing portable measurement solutions generated strong interest from many enterprises seeking to build efficient and secure digital inspection loops, laying a solid foundation for potential future collaboration.

Insights into Advanced Technologies and Industry Trends

The conference agenda focused on three core areas: “Advanced Forming, Intelligent Manufacturing, and Smart Inspection,” featuring high-level keynote speeches and expert reports.

To bolster innovation in domestically developed technologies, discussions on intelligent manufacturing covered critical topics such as customization for non-standard aerospace components and key CNC machining technologies. A consistent emphasis was placed on the practical application and indispensable role of intelligent inspection—powered by tools like portable coordinate measuring machines—within integrated product design, manufacturing, and production lines.

Conclusion: PMT’s Role in the Future of Aerospace Manufacturing

PMT’s participation in AIMC 2025 not only showcased its leading-edge portable measuring arms but also reinforced its commitment to driving innovation in the aerospace sector. By offering highly accurate and portable measurement solutions, PMT is positioned as a leader in precision measurement technology, playing a vital role in the future of intelligent aerospace manufacturing. The event also laid the foundation for future collaborations, reinforcing the importance of continued innovation and partnerships in the rapidly evolving aerospace industry.

The post PMT Showcases Portable Measurement Solutions at AIMC 2025 appeared first on PMT Technologies.

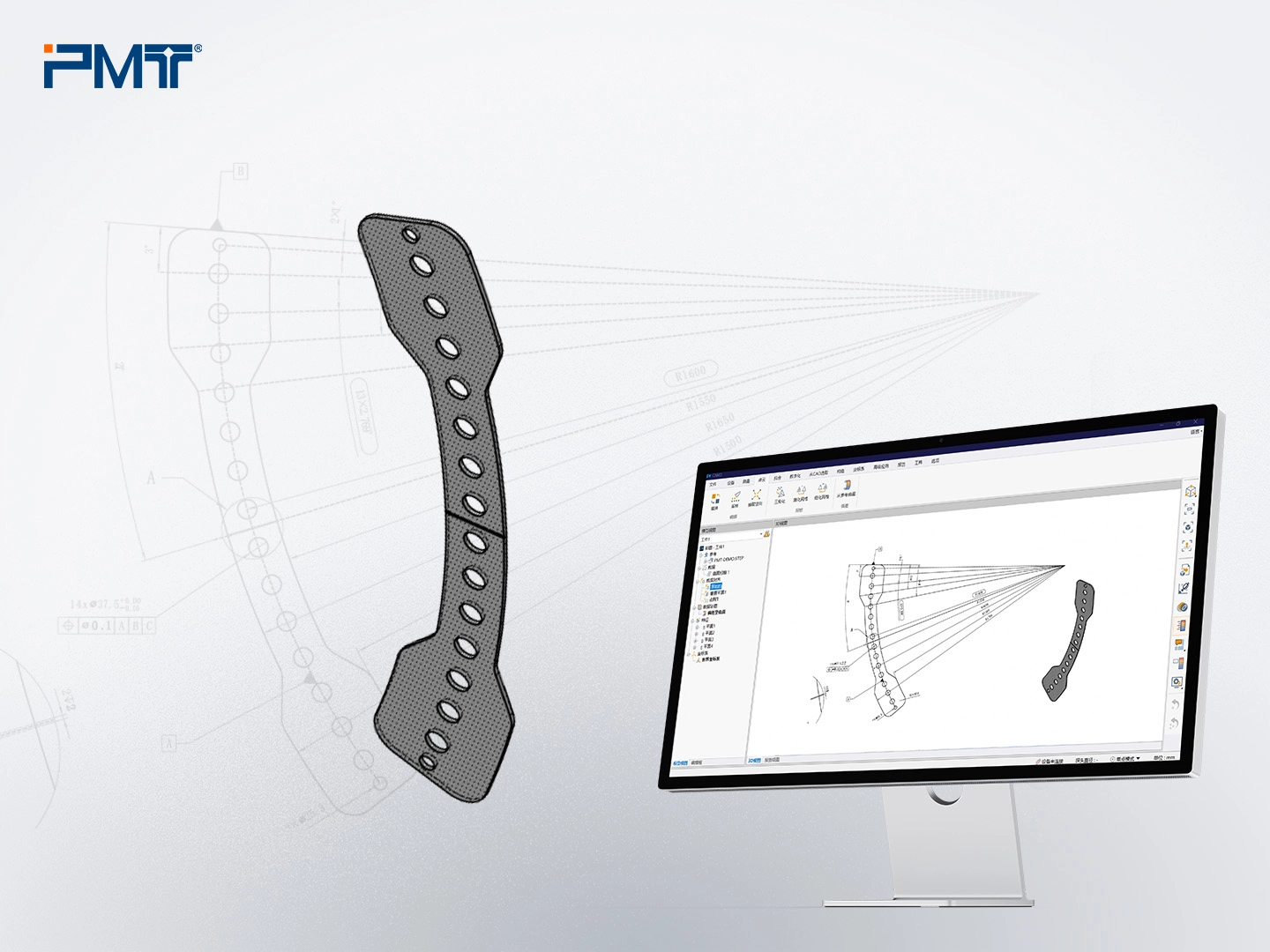

]]>The post What to Pay Attention to When Measuring Sheet Metal Parts appeared first on PMT Technologies.

]]>

Understand the Material Properties

To begin with, it is important to recognize that sheet metal has unique characteristics compared to thicker or more rigid parts. Its thin structure makes it more sensitive to pressure, temperature changes, and external force. This means that when measuring sheet metal, the wrong setup or technique can easily cause distortion, leading to inaccurate results. Therefore, the first step in successful measurement is to fully understand the properties of the material and adapt the method accordingly.

Control the Measurement Environment

Moving from material understanding to conditions, the environment in which measurements are taken plays a big role in accuracy. Sheet metal can expand, shrink, or warp when exposed to changes in temperature or humidity. Vibrations in the workshop can also affect sensitive measuring tools. For this reason, it is recommended to use a stable environment with controlled temperature and minimal external interference. Proper environmental control ensures consistent and reliable data.

Choose the Right Measuring Tools

Another key factor is selecting the right measuring equipment. Traditional gauges and calipers may not always deliver the precision required for complex sheet metal parts. Instead, advanced solutions such as portable measuring arms and coordinate measuring machines provide higher accuracy and flexibility. Portable Measuring Arms allow operators to measure large or irregular parts directly on the shop floor, while?CMMs?are ideal for highly detailed dimensional inspections. Choosing the right tool depends on the shape, size, and tolerance requirements of the sheet metal part.

Prevent Deformation During Measurement

As we shift from tools to technique, preventing deformation becomes critical. Even light pressure from a probe or clamp can bend thin sheet metal, resulting in false readings. To avoid this, non-contact methods, such as laser scanning attached to a portable measuring arm, can be used for delicate areas. If contact methods are required, ensure the part is properly supported to maintain its natural shape during inspection. Handling the part carefully throughout the process minimizes errors caused by deformation.

Pay Attention to Clamping and Positioning

Beyond the measuring process itself, clamping and positioning also deserve careful consideration. Incorrect fixturing can distort the part before measurement even begins. Fixtures should be designed to hold the part securely without adding stress or force that changes its geometry. Positioning must also allow clear access for the measuring tool to reach all critical points. A well-designed setup improves efficiency and accuracy, especially when working with complex or large sheet metal structures.

Use Consistent Measurement Standards

Finally, consistency in measurement standards ensures reliable results across different processes and teams. Always follow industry standards, customer requirements, or company guidelines when inspecting sheet metal parts. Aligning with these standards not only reduces the chance of error but also ensures that measurements can be compared and verified. Documenting the process and using the same reference points during each inspection helps maintain quality control over time.

Conclusion

Measuring sheet metal parts requires more than just accurate equipment—it demands attention to material properties, environment, clamping, and technique. By choosing the right tools, such as Portable Measuring Arms and Coordinate Measuring Machines, manufacturers can achieve precise results while avoiding common challenges like deformation. Careful planning and consistent standards will help maintain high quality in sheet metal production.

If you are looking for a reliable coordinate measuring machines supplier, PMT offers advanced solutions with strong expertise in measurement technology. Contact PMT today to learn more about how our products can support your quality control needs.

The post What to Pay Attention to When Measuring Sheet Metal Parts appeared first on PMT Technologies.

]]>The post Why CMM Calibration Is So Important appeared first on PMT Technologies.

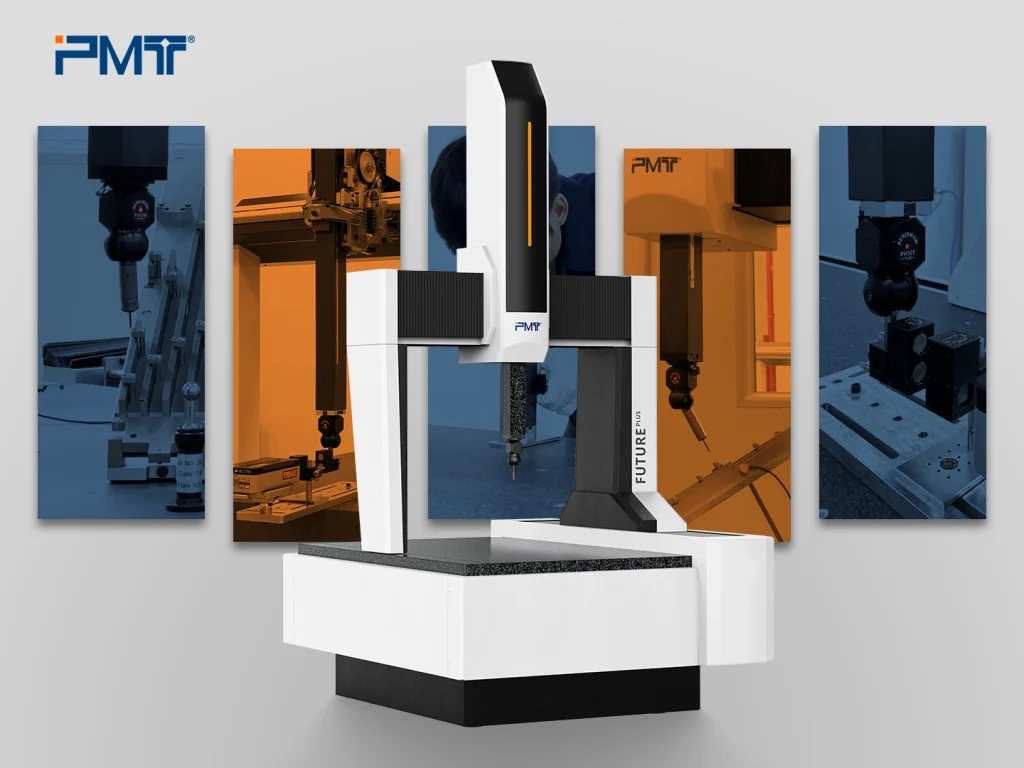

]]>Understanding CMM Calibration

To begin, it is important to understand what CMM calibration means. Calibration is the process of comparing the measurements of a CMM?with known standards to verify its accuracy. If any deviation is found, adjustments are made to bring the machine back to the required precision level.

In simple terms, calibration ensures that the measurements your CMM provides are both accurate and reliable. Without it, even the best coordinate measuring machines can drift out of tolerance, leading to errors in quality control.

Why CMM Calibration Matters for Quality Assurance

One of the main reasons calibration is so critical is its direct impact on quality assurance. Manufacturers rely on CMMs to validate that every part produced meets design specifications. If the CMM is inaccurate, faulty parts can pass inspection and reach customers.

This not only damages trust but can also result in expensive recalls, safety risks, and production delays. With regular calibration, companies can ensure their CMMs deliver trustworthy results, maintaining consistency across all measurement tasks.

Compliance With Industry Standards

In addition to quality assurance, CMM calibration is essential for meeting industry standards. Many sectors, such as aerospace, automotive, and medical device manufacturing, have strict requirements for measurement accuracy. Standards like ISO and ASME require companies to provide documented proof that their measurement equipment is properly calibrated.

Without calibration records, companies may fail audits, lose certifications, or face legal and contractual consequences. Regular calibration therefore helps manufacturers not only maintain precision but also stay compliant with international regulations.

Reducing Costly Errors and Downtime

Another reason calibration is important is the financial impact of measurement errors. If a CMM produces inaccurate data, entire production batches may be rejected, reworked, or recalled. This results in wasted time, higher costs, and potential loss of business.

By keeping CMMs calibrated, manufacturers minimize these risks. A well-calibrated machine prevents incorrect measurements, reduces rework, and lowers scrap rates. In addition, calibration helps detect potential machine issues early, avoiding unexpected downtime and repair costs.

How Often Should CMMs Be Calibrated?

The frequency of calibration depends on several factors, including how often the CMM is used, the type of parts being measured, and the environmental conditions of the workspace. For example, machines used in high-precision industries or harsh environments may require more frequent calibration.

While manufacturers often follow annual calibration schedules, best practices involve monitoring usage and performance closely. Any signs of measurement drift or changes in machine performance should prompt recalibration to maintain accuracy.

The Role of Professional Calibration Services

It is also important to note that calibration should always be carried out by trained professionals using certified equipment. Professional calibration services follow international standards and use traceable measurement tools to ensure reliable results.

Attempting to calibrate a CMM without the right knowledge or equipment can lead to further errors. Partnering with qualified providers guarantees that the machine continues to perform at its highest level, giving manufacturers peace of mind.

Building a Culture of Precision

Ultimately, CMM calibration is not just a technical requirement but a part of building a culture of precision and quality in manufacturing. By treating calibration as a routine necessity, companies reinforce their commitment to accuracy, reliability, and customer satisfaction.

In today’s competitive industries, where tolerances are tighter and demands are higher, a calibrated CMM can make the difference between meeting client expectations and falling short.

Conclusion

In summary, the importance of CMM calibration cannot be overstated. It ensures accuracy in measurements, supports quality assurance, maintains compliance with industry standards, reduces costly errors, and protects business reputation. By investing in regular calibration, manufacturers safeguard their operations and strengthen their competitive edge.

If your company is looking for reliable solutions in precision measurement, PMT is a trusted coordinate measuring machines supplier. With expertise in portable measuring arms, laser scanners, and advanced CMMs, PMT provides high-quality products and services that help manufacturers maintain accuracy and efficiency. Get in touch today to learn how PMT can support your measurement needs.

The post Why CMM Calibration Is So Important appeared first on PMT Technologies.

]]>The post PMT Portable Measuring Arm: A Key Solution in Driving Precision of Industrial Grippers in Automation appeared first on PMT Technologies.

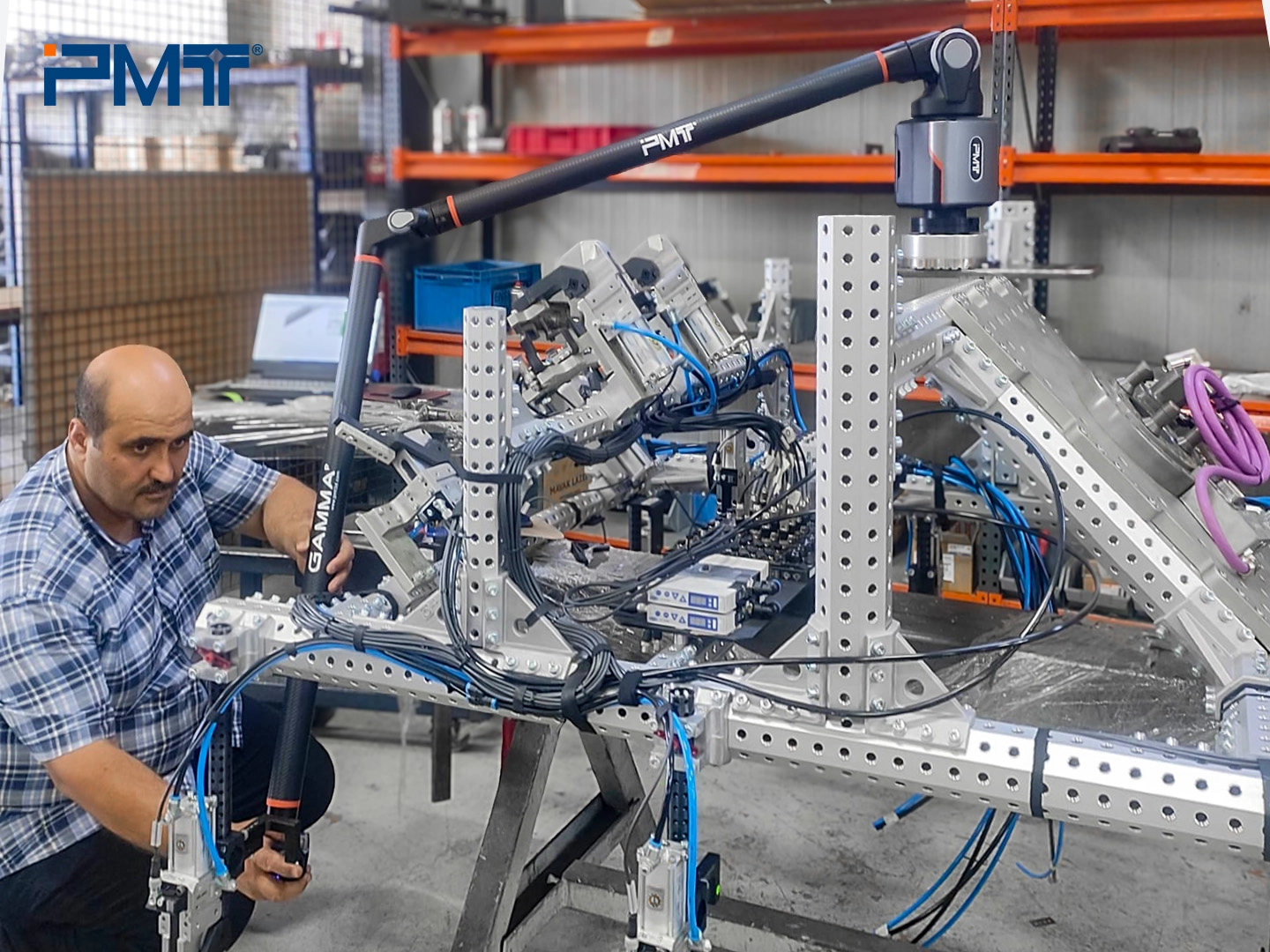

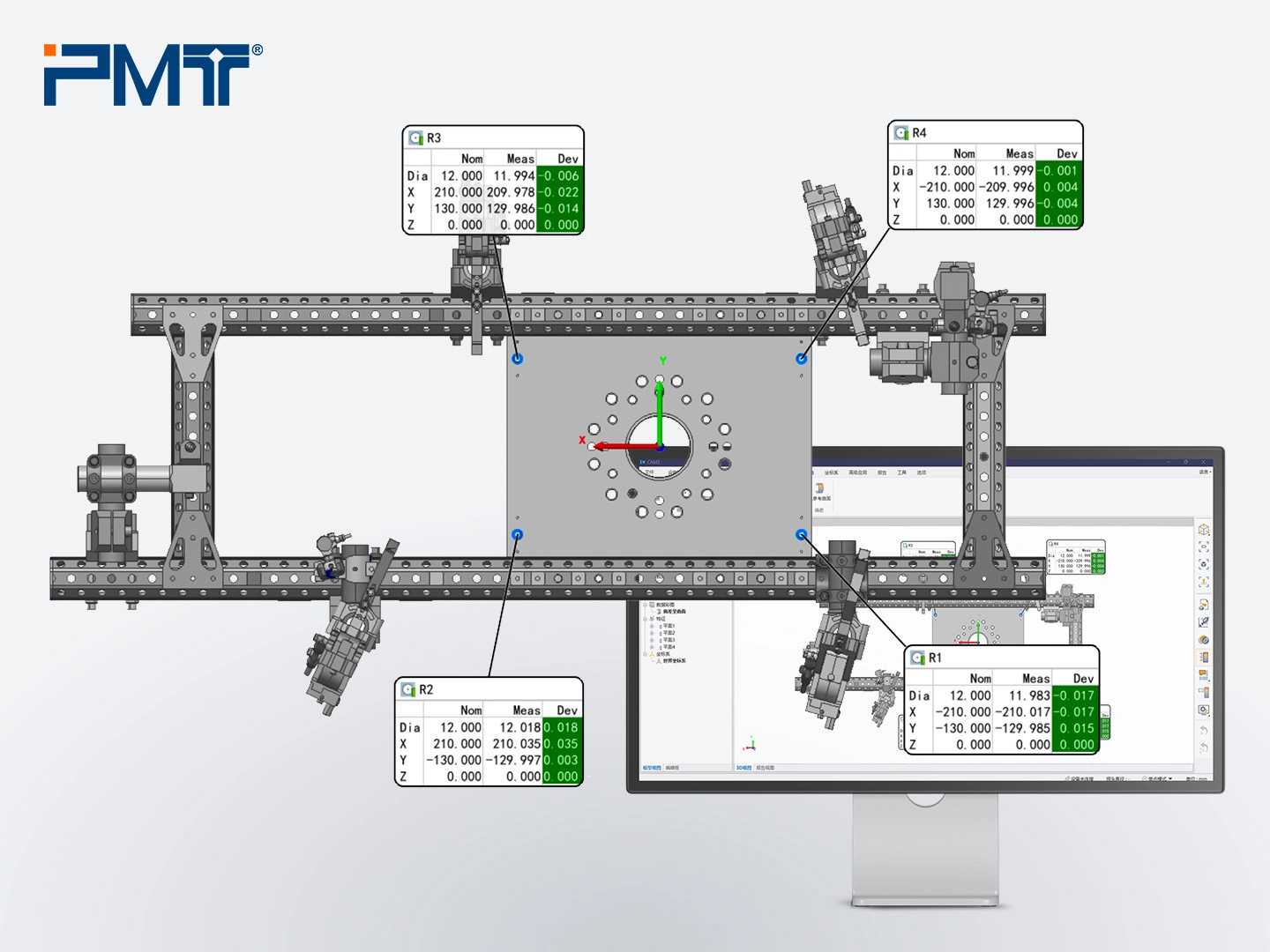

]]>An octagonal tube gripper is a fixture designed for industrial automation lines, enabling robots to automatically grip and handle workpieces. The gripper’s main structure is made of octagonal aluminum alloy tubes, available in various sizes with evenly spaced mounting holes. The tubes are assembled using blind rivet nuts and connectors, allowing gripping units to be installed at multiple angles and positions. This flexibility allows them to handle workpieces of various shapes and sizes, streamlining the design process and enhancing production efficiency.

Measurement Challenges

Despite the clear advantages of octagonal tube grippers, what challenges arise during the pre-assembly and re-measurement processes?

1. Human Assembly Errors

Octagonal tubes are uniform in shape, and during assembly, the connector positioning depends on manually calculated hole placements. This human-driven process can lead to misaligned holes, preventing proper grip and accurate workpiece handling.

2. Force Majeure

The sequence in which screws are tightened can cause slight, uncontrollable rotations between connected tubes, affecting the gripper’s ability to maintain precise alignment and grip on the workpieces.

3. Gravity-Induced Deformation

For larger parts (e.g., automotive side panels), the gripper may exceed 2 meters in length. During robotic movement and angle adjustments, gravity can cause deformation, impacting the gripping accuracy.

Measurement Solution with PMT Portable Measuring Arm

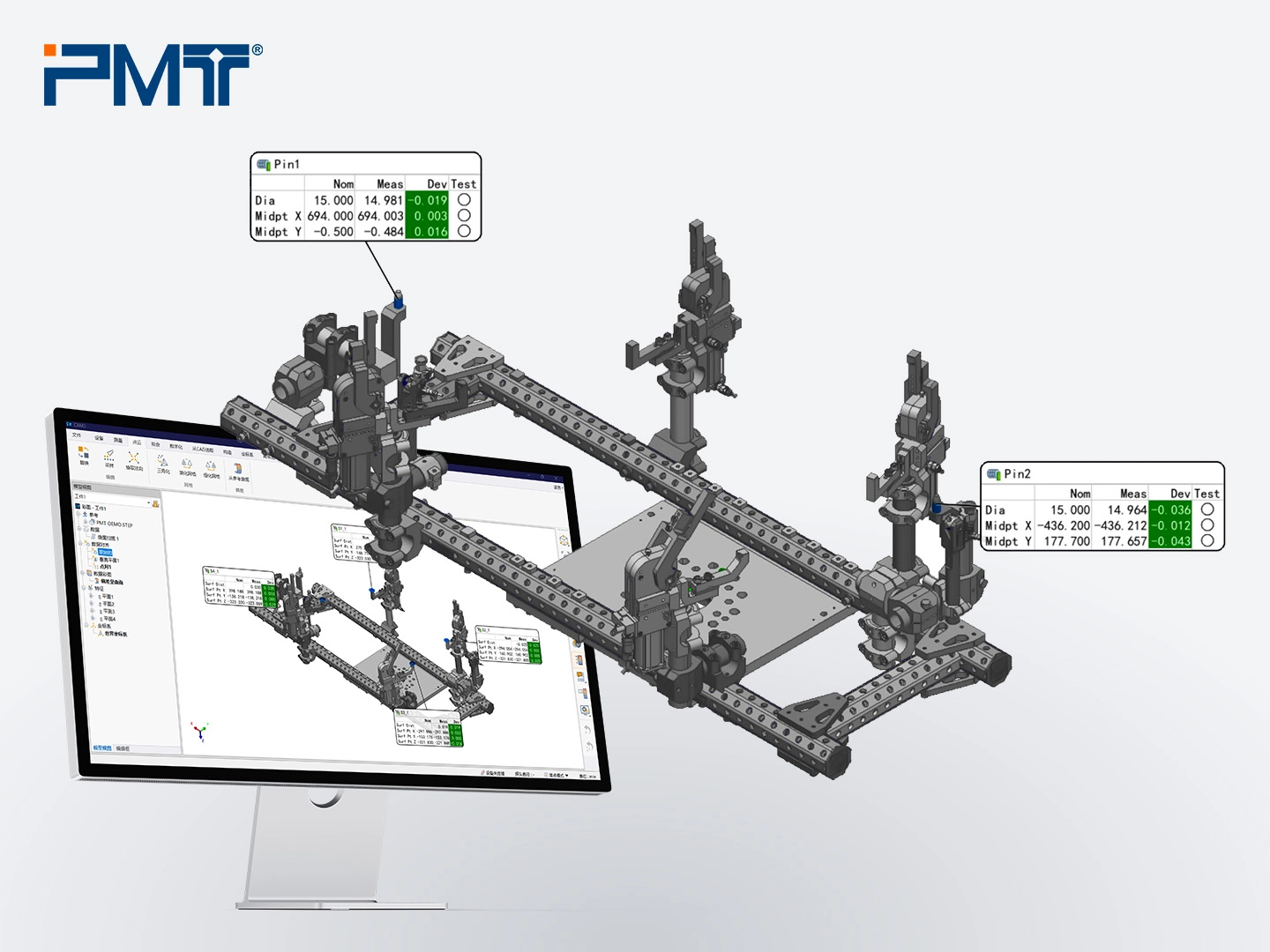

To tackle the challenges mentioned above, the portable measuring arm provides an ideal solution, offering portability and high efficiency for both the assembly and inspection processes of octagonal tube grippers. This case study highlights how a leading automation solutions provider in Turkey used the PMT portable measuring arm to solve critical production issues, enhancing accuracy and efficiency in their manufacturing process.

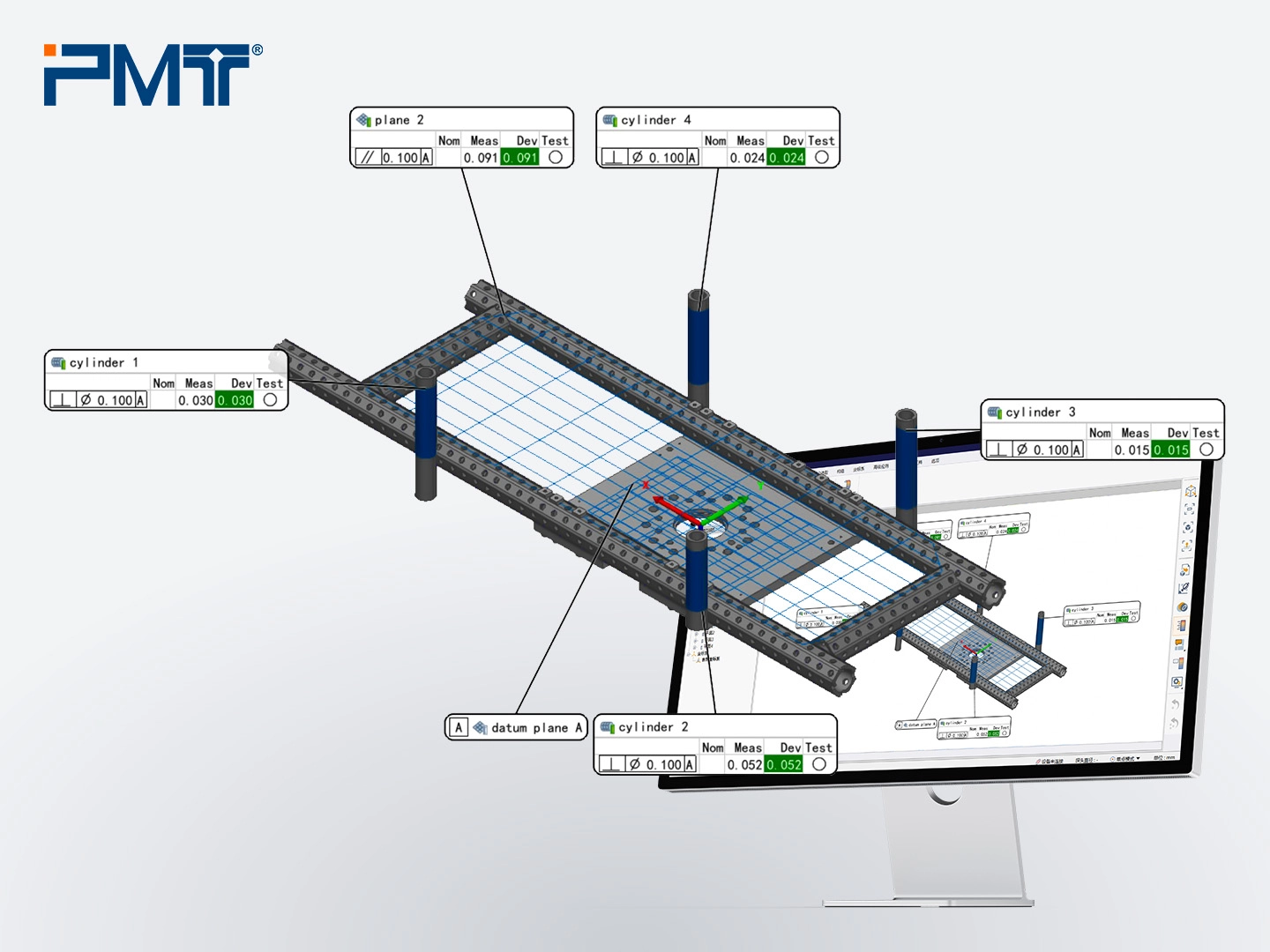

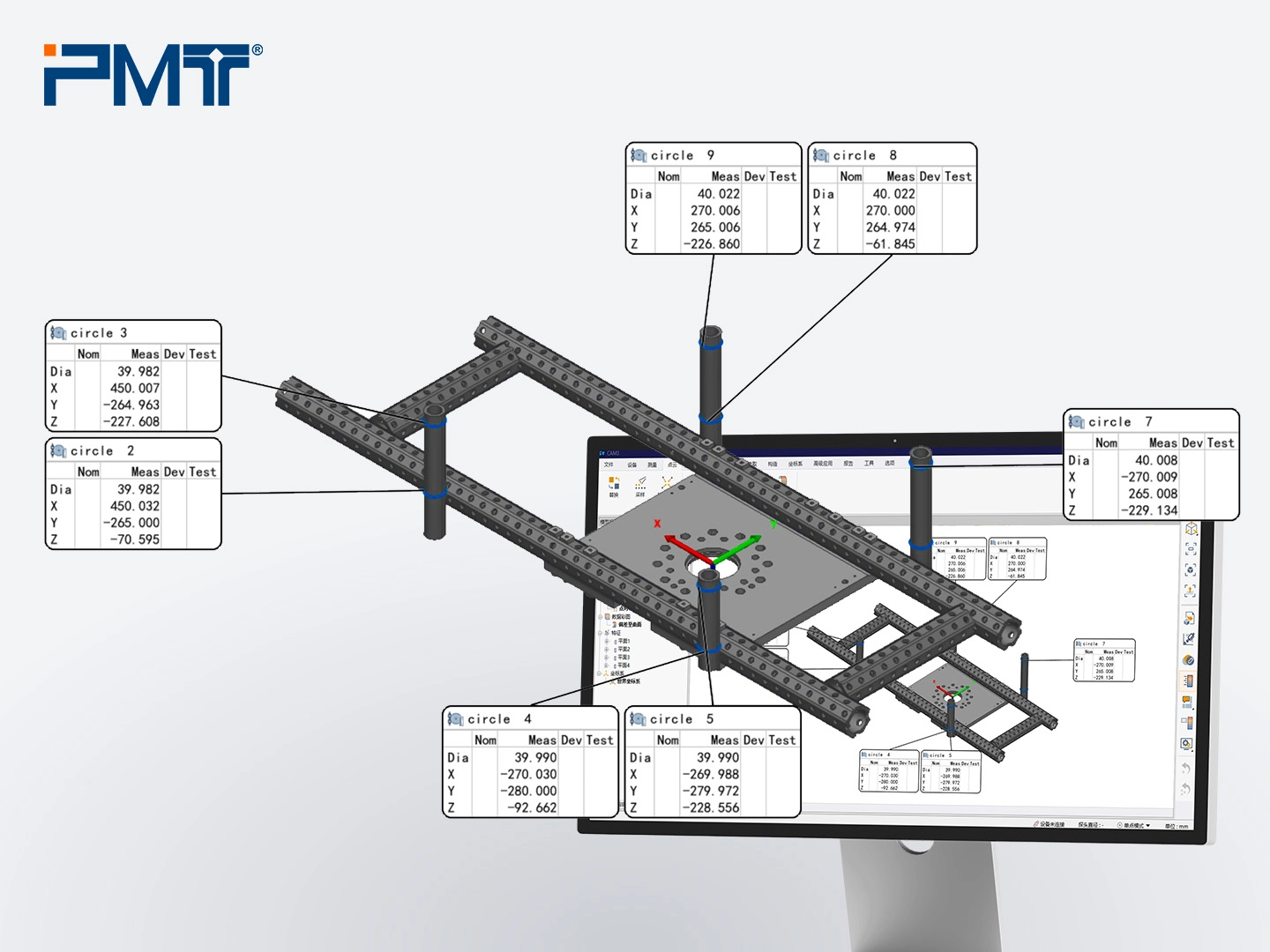

A. Measurement Solution for the Assembly Process

The PMT measuring arm enables real-time inspection of the concentricity and perpendicularity between the gripper and robot flange, as well as the parallelism and perpendicularity between tubes. This helps detect and prevent failures caused by accumulated errors.

By aligning the pinholes on the connecting plate with the CAD model, misaligned holes in the assembly can be quickly detected and corrected, ensuring rapid response and maintaining assembly accuracy.

Measurement Steps

1. Use the portable measuring arm’s probe to contact the reference holes on the connector plate, then apply Best-Fit to align the gripper with the CAD model in 3D measurement software.

2. Measure the connector plate plane and define it as Datum A. Then measure the main frame plane and the cylindrical vertical tubes of other grippers to assess parallelism and perpendicularity.

3. If deviations exceed tolerance, construct features (e.g., circles on cylindrical tubes) and compare XY coordinates at different heights to calculate required adjustments. This step ensures assembly accuracy.

4. Measure gripping unit. The gripping units typically includes cylindrical locating pins, fixing blocks, and chuck blocks. Measure the locating pins using the cylinder feature, and use Build/Inspect to measure the fixing blocks. Chuck blocks are adjusted relative to the blocks and don’t require direct measurement. Compare all measured features with the CAD model to determine necessary adjustments.

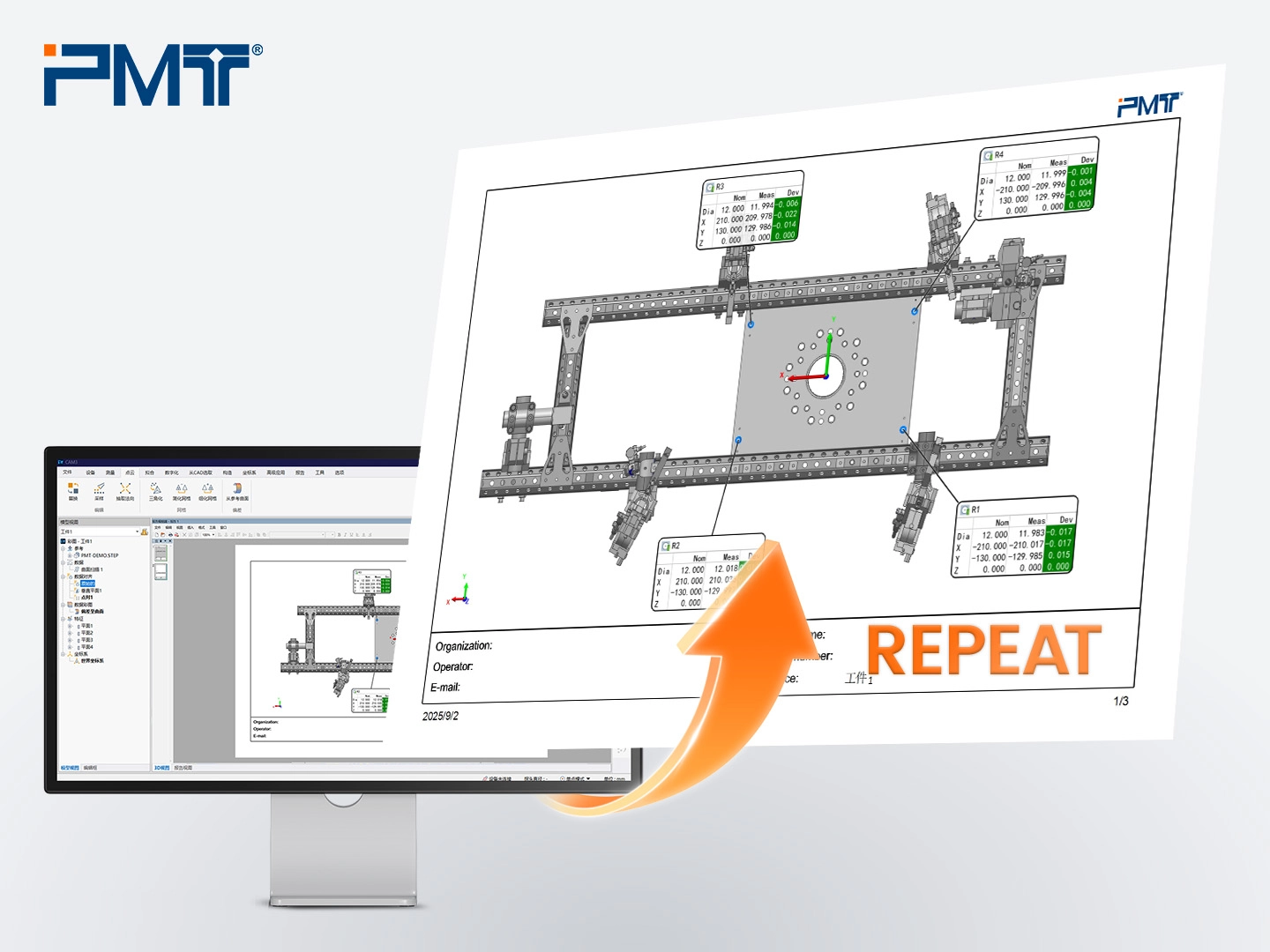

5. Adjust the gripping modules according to the 3D comparison results until all deviations are within tolerance. Then, export the export in PDF format.

B. On-Site Re-Measurement of the Gripper

After the octagonal tube gripper passes initial measurements, it may still undergo slight deformation due to vibrations or external forces during transportation. Therefore, re-measuring the gripper on-site with a portable CMM is essential after installation. This ensures the gripper’s performance and confirms its precision.

The re-measurement process mirrors the initial factory checks, typically requiring only a 3D comparison to verify the gripping unit’s accuracy.

C. Robot Calibration Assistance

Once the gripper’s accuracy is confirmed, robot calibration can be performed on the welding fixtures. First, establish a coordinate system using the gripper’s fixture and define the robot’s movement trajectory. Next, use a portable measuring arm to measure the coordinates of at least four fixed datum holes along the trajectory. Finally, input these values into the robot’s system to complete the calibration.

Customer Feedback

The Turkish customer shared that before purchasing the PMT portable measuring arm, they outsourced most measurement tasks. However, since a recent surge in orders, shorter delivery times, and externally sourced materials made scheduling measurements difficult, which significantly driving up production costs.

Since acquiring the PMT Arm, these issues have been resolved. After just two days of training, the company’s fitters quickly mastered the device. The integrated workflow has eliminated installation errors and significantly reduced costs on outsourced measurements.

Conclusion

Octagonal tube grippers are widely used in the automotive welding and automation industries for their modular design, high strength, easy assembly, and long lifespan. Moreover, the portable coordinate measuring machine ensures high precision, portability, and rapid 3D inspection, making it crucial for both verifying the gripper’s accuracy before shipment and shortening delivery times while reducing costs. Therefore, the measuring arm has become an indispensable tool in the production process of octagonal tube grippers.

The post PMT Portable Measuring Arm: A Key Solution in Driving Precision of Industrial Grippers in Automation appeared first on PMT Technologies.

]]>The post Portable Measuring Arm: A Professional Solution for Large-Diameter Valve Inspection appeared first on PMT Technologies.

]]>The Challenge of Large-Diameter Valve Inspection

Large valves often feature wide openings, heavy structures, and intricate inner and outer surfaces. These characteristics make them difficult to inspect with conventional measurement tools such as calipers or fixed CMMs. The main issues include limited measuring range, difficulty in accessing hidden areas, and time-consuming setup processes. As a result, many industries face delays, higher costs, and risks of quality problems when relying solely on traditional methods.

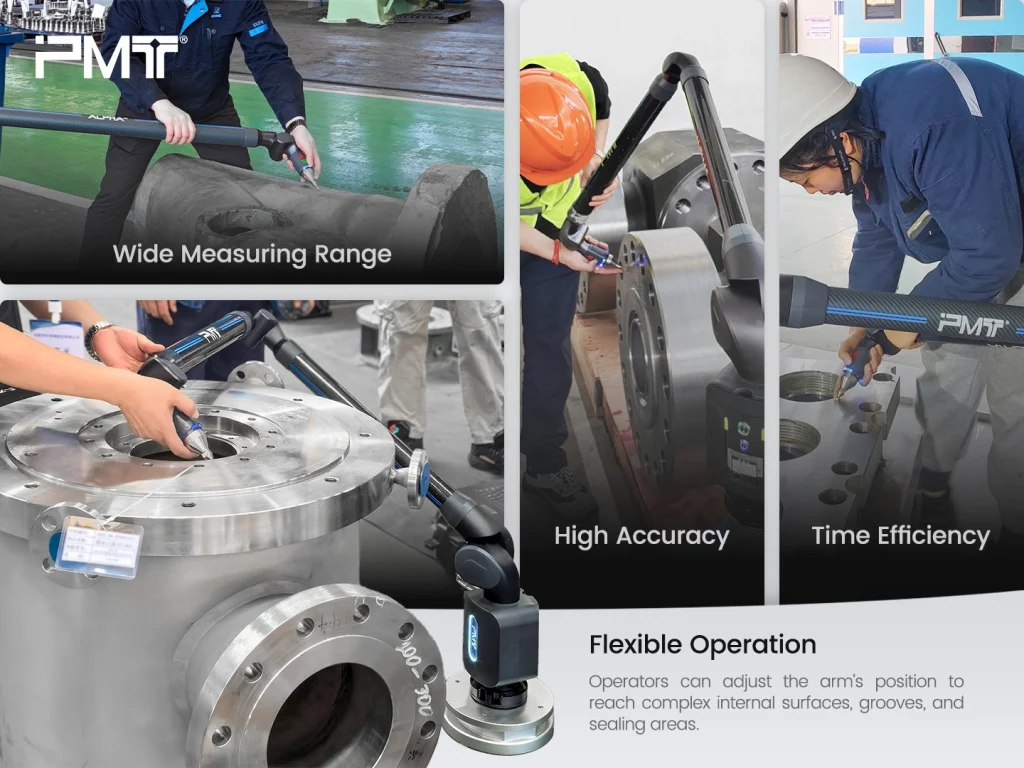

Why Portable Measuring Arm is the Right Solution

Compared with other inspection tools, the portable measuring arm?stands out because it is lightweight, easy to move, and flexible to use directly on the shop floor. It allows operators to measure large workpieces without moving them to a fixed inspection room, saving both time and effort. For large-diameter valves, this mobility ensures that even the deepest internal structures and widest external surfaces can be accurately inspected.

Key Advantages in Valve Body Measurement

To understand its value better, let’s look at the specific benefits of using a portable measuring arm in valve body inspection:

- Wide Measuring Range: The arm can easily cover large diameters that exceed the capability of standard gauges or handheld tools.

- High Accuracy: Despite its mobility, the system maintains strong precision, providing reliable data for quality control.

- Flexible Operation: Operators can adjust the arm’s position to reach complex internal surfaces, grooves, and sealing areas.

- Time Efficiency:?On-site inspection reduces downtime, as there is no need to transport heavy valves to a separate measuring facility.

These advantages directly help industries improve product quality and reduce inspection costs.

Practical Applications in the Valve Industry

In real-world applications, portable measuring arms are commonly used to measure valve body diameter, roundness, flange flatness, and alignment of internal passages. For example, when producing a high-pressure valve, every detail of the sealing surface must meet strict standards. With a portable measuring arm, technicians can quickly identify any deviation and make adjustments before final assembly. This ensures higher reliability and reduces the chance of leakage or operational failure in the field.

Improving Efficiency and Reducing Costs

Another key benefit of using portable measuring arms is the improvement in overall efficiency. Traditional methods require several tools and multiple steps, while portable arms allow all measurements to be performed in one setup. This not only saves time but also reduces human error. By cutting unnecessary processes and improving accuracy, manufacturers can significantly lower inspection and rework costs.

Future Outlook in Large-Scale Valve Inspection

Although many tools are used in industrial inspection, portable measuring arms are becoming increasingly important for large and heavy components. Their combination of precision, mobility, and efficiency makes them a valuable tool for valve manufacturers and end-users. As industries continue to demand higher quality and faster production cycles, the role of portable measuring arms in large-diameter valve inspection will only grow stronger.

Conclusion

Inspecting large-diameter valves has always been a difficult task due to their size and complexity. However, with the use of the Portable Measuring Arm, industries can achieve accurate, efficient, and reliable measurement results. From reducing inspection costs to improving product quality, this technology has proven to be an effective solution for one of the most challenging tasks in valve production. For manufacturers aiming to stay competitive, adopting portable measurement tools is no longer an option—it is a necessity.

The post Portable Measuring Arm: A Professional Solution for Large-Diameter Valve Inspection appeared first on PMT Technologies.

]]>The post Measuring Arm: Differences Between Contact and Non-Contact Measurement Methods appeared first on PMT Technologies.

]]>

Introduction to Measurement Methods

Measurement methods are used to capture the size, shape, and surface characteristics of an object. They are essential in industries such as manufacturing, automotive, aerospace, and electronics, where quality and precision are critical. While both contact and non-contact methods aim to deliver accurate results, their working principles and applications are very different.

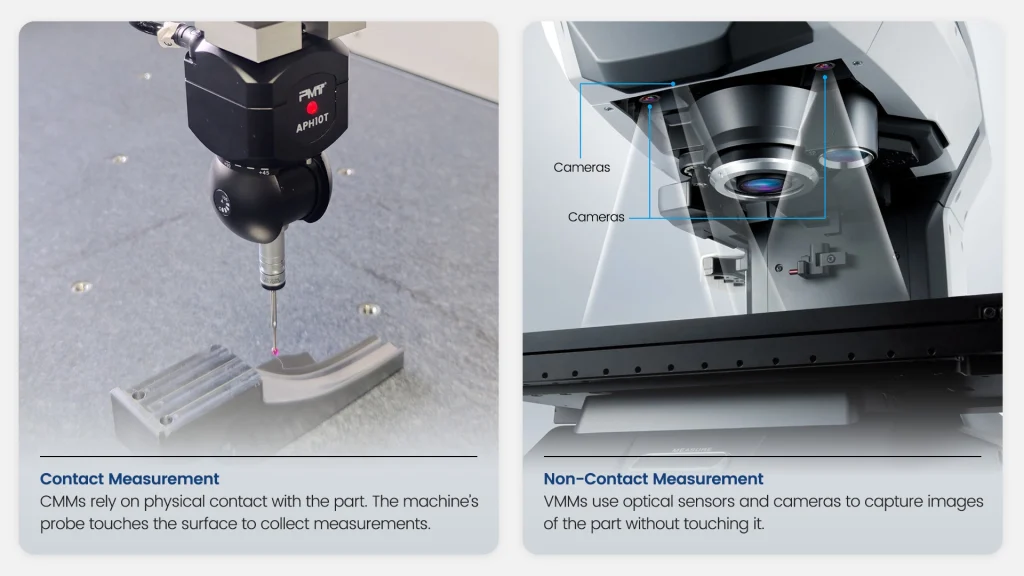

What is Contact Measurement?

Contact measurement is a method in which a physical probe touches the object to record its dimensions. The most common example is the coordinate measuring machine (CMM), where a probe makes direct contact with specific points on the part. Portable measuring arms also use this principle to capture 3D data. This approach is valued for its high accuracy and reliability, especially when checking geometric tolerances.

Unlike traditional coordinate measuring machines (CMMs), measuring arms typically use zircon ball probes, while ruby ball probes may deliver superior performance in specific measurement scenarios. This versatility contributes to their ease of use and operational flexibility.

It should be noted that contact measurement with a measuring arm requires direct physical contact with the surface, which makes it less ideal for measuring delicate, deformable, or highly curved components.

What is Non-Contact Measurement?

In non-contact measurement, laser measuring arms are used to capture data without physically touching the part. This method is much faster and can collect a large amount of data points in a short time. It is especially effective for measuring complex surfaces, fragile components, or soft materials that might be damaged by direct contact. Non-contact measurement is also widely used in digital modeling, reverse engineering, and quality inspection of free-form surfaces.

Measuring Arm VS. Scanner for Measuring Arm

When comparing accuracy, contact measurement usually provides the highest precision, making it suitable for critical applications that require tight tolerances. Non-contact systems, while slightly less accurate in some cases, are much faster and can handle large volumes of measurement data.

For example, a portable measuring arm with a probe may take time to check each point, whereas a laser scanner can capture thousands of points instantly. Companies often balance precision and efficiency depending on their needs.

| VS | Measuring Arm | SCANNER for Measuring Arm |

| Basic Principle | Touch the probe to the part surface, acquire each points’ 3D coordinates with axis encoders. | Laser projects onto surface; sensor captures reflected light to collect dense point cloud. |

| Measurement Accuracy | 0.12-0.55mm | 0.024-0.101mm |

| Measurement Speed | High, caution with curved and soft surfaces | Extremely high, capture 1,200,000 points/sec |

| Measurement Object | Regular features: holes, cylinders, planes, slots | Complex free-form surfaces, irregular shapes, soft/deformable objects: rubber parts, clay models |

| Impact on workpiece | Contact – low force with zircon probe | Non-Contact – zero force, no risk of surface damage |

| Application | Quality Inspection&Control:

machined parts, gears, bearings, fixtures, gauges; GD&T Report Generation. |

Reverse Engineering:

Digitizing parts without CAD models Inspection&Comparison: Sheet metal, sculptures, artifacts, automotive interiors; Digital Archiving. |

| Operation Difficulty | Easy, low training required | Easy, requires scan path planning & point cloud processing |

| Cost | Low | High |

| Environment Requirement | Temp: 5℃-45℃

RH: 0-95℃ |

Temp: 5℃-45℃

RH: 0-95℃ |

Choosing the Right Measurement Method

Different industries choose measurement methods based on their production demands. Except for specialized fields like cultural relics preservation, contact and non-contact measurement methods often overlap in application. The choice between them depends on factors such as material type, required accuracy, production speed, and cost efficiency. For industries that need detailed precision checks, contact measurement remains the first choice. Conversely, for applications involving complex geometries or rapid inspections, non-contact methods provide significant advantages.

In many modern factories, a combination of both methods ensures the best balance of accuracy, speed, and flexibility.

Conclusion

In summary, the main differences between contact and non-contact measurement methods lie in their working principle, accuracy, speed, and applications. Contact methods provide unmatched precision, while non-contact methods offer speed and adaptability. Both play an important role in modern industry, and using them effectively ensures high-quality production and process efficiency.

The post Measuring Arm: Differences Between Contact and Non-Contact Measurement Methods appeared first on PMT Technologies.

]]>The post Today’s Topic: How PMT’s Portable Measuring Arm Benefits the Wind Energy Industry? appeared first on PMT Technologies.

]]>Amid the global energy transition and climate change, wind energy plays a crucial role as a key renewable source. To support the sustainable growth of wind energy enterprises, it is essential to establish databases of key components and performance indicators, integrate digital information into quality control systems, and shift from manual operations to intelligent, technology-driven manufacturing.

As a result, sustainable measurement solutions have increasingly become a reliable foundation for the industry’s continued development.

How does PMT Support the Wind Energy Industry?

PMT’s independently developed portable coordinate measuring machine (CMM), also known as a portable measuring arm, has been widely used in the wind energy industry for its precise GD&T analysis and strong on-site adaptability. It significantly enhances manufacturing accuracy and installation quality, while enabling real-time inspection, rapid feedback, and timely correction.

By delivering accurate measurements anytime and anywhere, PMT portable measuring arm helps lower costs, enhance productivity, and ensure operation safety, making quality control more efficient and contributing to the sustainable growth of the wind energy industry.

Why Choose a Portable Measuring Arm?? Key Benefits of PMT Arm

During a visit to a customer site in Poland, a chief engineer was seen using the PMT portable measuring arm to inspect wind turbine blades alongside his technical team. To better understand user feedback and strengthen cooperation, PMT conducted a brief on-site interview.

PMT Technologies: What do you think about the PMT Arm so far?

Chief Engineer: It’s lightweight and easy to move around the shop floor. As you can see, we have multiple production areas, it would be impossible to move a traditional CMM across several scenarios. That’s why we chose the portable measuring arm, which is more convenient for us.?

PMT Technologies: Exactly. The PMT portable measuring arm allows for on-site flexible measurement, saving both time and cost, especially in the wind power industry.

Chief Engineer: And it’s also very easy-to-use compared to a traditional CMM. Our engineers even don’t need to learn programming. They just touch the probe to the workpiece, then the 3D software collects data and constructs features quickly with its geometric functions.

PMT Technologies: Right. Even in environments where temperatures fluctuate, like during wind equipment manufacturing and installation, PMT Arm’s smart temperature compensation system automatically adjusts the data in real time. Unlike fixed coordinate measuring machines, the portable CMM doesn’t require a climate controlled room while still maintaining high accuracy.

How Easy is it to Use a Portable Measuring Arm for Measurement?

After a 3-day on-site training provided by a PMT technical engineer at the customer’s site, the operator will have mastered all measurement skills and will be fully capable of independently performing all measurement tasks.

1.Drawing Analysis & GD&T Feature Capture

Compare the workpiece with its drawing, analyze key requirements, and use the portable measuring arm to measure features like planes, circles, and cylinders quickly and accurately.

2.CAD Model Import & GD&T Evaluation

For complex parts with multiple sizes on site, import the CAD model and establish a coordinate system. This allows for precise GD&T analysis to verify assembly quality and dimensional accuracy.

3.Data Collection & Analysis

Use the measuring arm to simply touch the surface of your workpiece, press button on the handle, and points will be automatically taken. Analyze the GD&T parameters such as holes, planes, and surfaces.

4.Batch Inspection & Report Generation

For random sampling or batch inspection, the portable measuring arm combined with 3D software helps streamline the process. All data is archived for traceability, supporting the development of a comprehensive quality control system.

What Tangible Benefits Can a Portable Measuring Arm Bring to Real-life Applications?

PMT portable measuring arms have been widely adopted across industries worldwide. In the wind energy sector, the measuring arm allows for on-site measurement and real-time adjustment without relocating the workpiece, significantly enhancing production efficiency and product quality. This innovative technology reduces labor and rework costs, delivering substantial economic benefits to customers. Overall, wind energy companies using the PMT Arm have achieved over a 30% reduction in production costs, providing reliable support for long-term sustainable growth.

The post Today’s Topic: How PMT’s Portable Measuring Arm Benefits the Wind Energy Industry? appeared first on PMT Technologies.

]]>The post Portable CMM: Contributes to High-accuracy and Efficient Adjustments in Automated Production Lines appeared first on PMT Technologies.

]]>

Portable CMM in Quality Inspection

In early 2020, the new energy vehicle industry gradually came to the fore. A new energy company was facing challenges with low efficiency and high rework rates due to outdated measurement methods, which resulted in limited production and reduced market competitiveness. After multiple visits, a PMT account manager suggested PMT ALPHAM 3.0m portable coordinate measuring machine (CMM), supplemented by folding adjustable tripod. This enabled the company to boost the pass rate of its key equipment, the lamination machine, to over 99.5%.

Core Advantages of PMT ALPHAM portable CMM:

1. Excellent Accuracy: Achieves up to ±0.02mm (In accordance with ISO 10360-12), providing reliable repeatability.

2. Cost-effective Performance: Balances precision and value, ideal for high-speed lamination machines.

3. Smart Integration: Enables real-time data assembly and archiving with PMT portable CMM and 3D software.

Lamination Machine Tooling Setup: Measurement of Pole Piece

“With traditional measurement methods, the pole piece alignment in our machine had a deviation of up to 0.15 mm, leading to a pass rate of just 91.7%. Now, by using a portable CMM with 3D software, we can adjust the pole piece alignment in real time. This has reduced the deviation to ±0.03 mm and boosted the pass rate by more than 7.8%, greatly improving both efficiency and yield,” A production manager from a top lamination machine company just shared.

Measurement Steps:

1. Establish the Coordinate System

Take the machine platform as the reference plane and the long side of the machine’s base (or the line of a circular hole) to establish the coordinate system.

2. Data Acquisition

Use the PMT portable CMM to inspect the flatness, perpendicularity, and parallelism of the mounting surfaces, checking excessive errors for further adjustments.

3. Real-time Adjustment

Evaluate the measured data: Green indicates pass, red indicates errors. Correct errors by loosening screws and adjusting gaps until tolerances are within limits.

4. Report Generation

Measure again the features and adjust any remaining errors until all meet requirements. Then the report can be generated and archived for future traceability.

Unwinding Machine Tooling Debugging: Diaphragm Tension Control

During the production of lithium battery, the unwinding machine feeds pole pieces to the lamination machine. Uneven diaphragm tension can cause wrinkles or tears, reducing the stability of the unwinding machine and leading to quality defects.

Building on previous success with the lamination machine, a factory, after discussions with the PMT account manager, decided to use the PMT ALPHA portable CMM to enhance the unwinding machine’s tension system. By measuring roller alignment and adjusting mounting surfaces, diaphragm tension fluctuations were reduced from ±8N to ±1.5N, cutting debugging time by over 65%. This significantly addressed diaphragm wrinkling and tearing, boosting both stability and productivity.

Conclusion

Through the Build/Inspect function in 3D software, the PMT portable CMM pioneers a comprehensive quality control process of “real-time measurement, dynamic feedback, and precise correction”. It helps significantly inject momentum into the automation industry with its cutting-edge accuracy, portability, and flexibility.

The post Portable CMM: Contributes to High-accuracy and Efficient Adjustments in Automated Production Lines appeared first on PMT Technologies.

]]>The post PMT Portable Coordinate Measuring Machine: A Booster for Product Quality Improvement appeared first on PMT Technologies.

]]>On July 19, 2025, China announced the commencement of the hydropower project in the lower reaches of the Yarlung Zangbo River in Nyingchi, a city in China’s Xizang autonomous region. As a key initiative under the country’s 14th Five-Year Plan, this project is of great importance in advancing China’s energy strategy, promoting economic development in border areas, and strengthening its international influence, while setting new global standards for hydropower development.

By utilizing the vast energy potential of the Yarlung Zangbo River, this groundbreaking project will also drive the growth of engineering machinery commonly employed in sectors like hydraulics, mining, railways, and highways in the nearby areas. These industries demand high performance under extreme working conditions, with a strong emphasis on manufacturing precision and quality stability.

As one of the core quality control methods in engineering machinery, PMT portable CMM (measuring arm) offers the advantage of measuring anytime and anywhere, providing innovative technical value throughout the R&D, production, and evaluation processes.

Applications in Engineering Machinery

1.? Measurement of Shield Machine (Small Machine & Main Shaft)

A shield machine plays a crucial role in tunnel excavation within engineering machinery. Currently, the front shield relies primarily on manual measurements, often resulting in significant errors due to inconsistent measuring positions and variations in worker skills and proficiency. Additionally, the confined space and complex working environment within the shield machine pose serious safety risks to personnel.

With its high portability and precision, the PMT measuring arm has found extensive application in this field, significantly reducing safety risks and enhancing the efficiency and automation of tunnel construction.

2.? Measurement of Casting Mold for Engine Cylinder Block

The casting mold of the engine cylinder block is designed to precisely shape steel into complex components. Its high precision is essential for enhancing engine performance and ensuring a reliable power supply.?

However, thermal deformation and wear during die casting can lead to dimensional inaccuracies, making regular size inspections crucial. The PMT portable measuring arm overcomes environmental challenges and removes the need for pre-set reference standards typically used in traditional methods. The PMT Arm’s highly adaptable measurement capabilities contribute to improving mold design.

3.? Measurement of Excavator Component

As the demand for diverse engineering tasks increases, modern excavators are designed to switch between multiple working attachments. They are indispensable in earth-moving operations during the early stages of hydraulic projects.

The PMT measuring arm delivers accurate measurements of critical dimensions on key excavator components. By probing critical areas and constructing geometric features such as planes, cylinders, and circles, the measuring arm can swiftly verify the width of installation grooves, parallelism, symmetry, and concentricity of mounting holes. This helps avoid installation problems and improper fittings caused by machining errors during production, ultimately ensuring the optimal performance of the equipment.

Quick adjustments can be made in real-time based on the probe’s coordinate values using the PMT Arm, thereby improving the accuracy and efficiency of component production and assembly.

4.? Measurement of Engineering Vehicle Chassis

The engineering vehicle chassis is essential for supporting loads in hydraulic projects, preventing deformation or fractures under heavy loads.

Typically welded from large steel or iron castings, chassis precision is impacted by self-weight and thermal deformation during welding, leading to potential post-cooling deformations.

Therefore, it’s crucial to use PMT portable measuring arm with software for routine inspections. The equipment evaluates GD&T features, such as concentricity and flatness of mounting holes, to ensure precise assembly and prevent defects that may lead to batch scrapping. This ultimately enhances the safety and reliability of engineering vehicles in the challenging working conditions of hydraulic projects.

5.? Measurement of Ore Crusher Station Frame

The ore crusher station frame provides support for crushing equipment, stabilizing its weight and withstanding impact forces during the processing of ores, rocks, and other materials.

Due to the large size of the frame, traditional measurement methods become difficult to apply, with some dimensions even being undetectable. The PMT measuring arm effectively verifies the consistency of drawings and samples, easily checking space dimensions and geometric tolerances. Additionally, the 7-axis measuring arm and SD laser line probe enable reverse verification of samples.

The PMT Arm’s features include the following aspects:

- Quick Installation: The PMT measuring arm can be easily and rapidly installed on-site.

- Quick Acquisition: Only four points are needed to measure planes, calculate flatness, and analyze deformation.

- Quick Measurement: Concentricity is measured without additional tools; simply measure the cylindrical feature and use the software’s axis construction function for quick

- Quick Verification: For reverse verification of complex surfaces on the crusher station, rapid scanning with portable CMM’s extended measurement range ensures accurate

Other Applications

The hydraulic project will also be applied in railway track laying and valve body manufacturing.

1.? Measurement of Rail Track

In large-scale projects, improving rail tracks or laying temporary tracks demands strict quality control. The PMT portable CMM offers precise geometric detection and maintenance, ensuring the stability and high quality of the rail track.

PMT measuring arm allows for rapid measurements of sample batches using the software’s “multipiece inspection” feature. This straightforward process allows for direct program saving and easy report archiving.

2.? Measurement of Valve Body

Valves are crucial for fluid control in hydraulic projects, regulating flow, controlling pressure, and preventing backflow.

The valve body constructs the flow path and withstands water pressure, requiring precise measurements for optimal functionality. The cylinder head ensures accurate linear or rotary movement, while ball valves rely on the valve stem’s rotation to open or close, ensuring proper pump station operation.

Therefore, it is essential to use the PMT portable measuring arm during valve manufacturing and maintenance to assess valve body deformation and sealing surface roughness.

The PMT portable measuring arm offers a full measurement range, high stability, portability, and efficiency, making it ideal for all stages of hydraulic construction including component validation, production monitoring, certification, after-sales analysis, and assembly accuracy, effectively meeting diverse measurement needs and improving product quality.

Conclusion

The hydropower project serves as a global model of national governance, significantly benefiting society and driving the development of related industries. Likewise, PMT has always been dedicated to supporting inspection processes with its self-developed measuring arms across industries, offering more professional “PMT solutions” worldwide.

The post PMT Portable Coordinate Measuring Machine: A Booster for Product Quality Improvement appeared first on PMT Technologies.

]]>The post What is the Difference Between CMM and VMM? appeared first on PMT Technologies.

]]>

What is a CMM (Coordinate Measuring Machine)?

A Coordinate Measuring Machine (CMM) is a precision tool used to measure the physical geometrical characteristics of an object. It uses a probe to touch the surface of a part and records its coordinates in 3D space (X, Y, and Z axes). These measurements are then processed to create detailed reports and models.

How CMM Works:

CMMs are equipped with various types of probes, such as mechanical touch probes, optical probes, and laser sensors. The probe moves along the axes and collects dimensional data, which is then converted into a 3D model or data report.

Applications of CMMs:

CMMs are widely used in industries like automotive, aerospace, and machining for tasks such as:

- Automotive: Checking the alignment and dimensions of engine parts.

- Aerospace: Measuring turbine blades and other complex components.

- Machining: Verifying the accuracy of fabricated parts.

Advantages of CMMs:

- High Accuracy: CMMs are known for their micrometer-level accuracy.

- Versatility: They can measure multiple dimensions, including size, shape, and position.

- Advanced Capabilities: Modern CMMs can be automated, improving consistency and efficiency.

What is a VMM (Vision Measuring Machine)?

On the other hand, a Vision Measuring Machine (VMM) is a tool that uses optical sensors and cameras to measure parts. Unlike CMMs, VMMs employ non-contact measurement methods, which are useful for delicate or soft materials that could be damaged by direct physical contact.

How VMM Works:

VMMs shine light onto a part’s surface and capture the reflected image with high-resolution cameras. The captured images are then processed by software to calculate dimensions and other features.

Applications of VMMs:

VMMs are ideal for measuring small, lightweight, or delicate parts. They are commonly used in industries like:

- Electronics: Measuring tiny components such as circuit boards.

- Medical Devices: Ensuring the precision of intricate medical instruments.

- Plastic Parts: Inspecting injection-molded components.

Advantages?of VMMs:

- Non-Contact Measurement: Ideal for fragile or soft materials.

- Speed: VMMs can perform fast measurements, making them suitable for high-volume production.

- Detailed Imaging: Capable of capturing complex shapes and small parts.

Key Differences Between CMM and VMM

Now that we’ve discussed both machines, let’s dive into their key differences. These differences are important when deciding which machine to use for your specific needs.

Measurement Method:

CMM: CMMs rely on physical contact?with the part. The machine’s probe touches the surface to collect measurements.

VMM: VMMs use optical sensors?and cameras?to capture images of the part without touching it.

Parts Suitability:

CMM: Best for rigid parts that can withstand physical contact. CMMs are not suitable for delicate or soft materials.

VMM: Ideal for delicate, deformable, or soft parts that could be damaged by contact-based measurements.

Accuracy:

CMM: Known for high accuracy—ideal for parts requiring micron-level precision, including 3D features and GD&T measurements.

VMM: While VMMs offer good accuracy, they are generally better suited for smaller or simpler parts and are less accurate for large, complex geometries.

Speed:

CMM: CMMs are typically slower because they measure one part at a time and are best suited for complex or large parts.

VMM: VMMs are faster, capable of measuring multiple parts simultaneously, making them perfect for high-volume production.

Workpiece Weight:

CMM: Can handle larger, heavier parts, with the capacity to measure components weighing up to 500kg.

VMM: Generally limited to lighter parts, typically under 20kg.

Cost:

CMM: CMMs tend to have a higher initial cost and maintenance requirements due to their mechanical complexity.

VMM: VMMs are typically more affordable and have lower maintenance costs.

Operator Skills:

CMM: Operating a CMM requires a skilled operator who understands how to set up and use the machine properly, especially for complex measurements.

VMM: VMMs are easier to operate, and less specialized training is needed.

When to Use CMM vs VMM

Choosing between a CMM and a VMM depends on several factors. Here’s when you should use each machine:

Use CMM When:

- Precise, 3D measurements are required for complex or large parts.

- You need to measure parts with specific GD&T features (e.g., flatness, parallelism, angularity).

- The parts are rigid and can withstand the probe’s contact.

Use VMM When:

- Measuring small, delicate, or soft parts that require non-contact measurement.

- Speed is a priority, and you need to measure multiple parts quickly in high-volume production.

- The parts are lightweight and do not require complex 3D measurements.

Conclusion

Both CMMs and VMMs are critical tools in ensuring product quality and precision in manufacturing. Each machine has unique capabilities that make it better suited for different tasks. CMMs offer high precision and versatility, making them ideal for complex or heavy parts, while VMMs provide fast, non-contact measurements, perfect for small, delicate, and high-volume parts.

Choosing the right measurement tool depends on the specific needs of your production process. By understanding the strengths and weaknesses of both machines, manufacturers can make more informed decisions and achieve better results in their quality control processes.

If you’re looking for a precise and efficient solution for your measurement needs, contact PMT?for expert advice on selecting the right CMM or VMM for your business. We provide comprehensive measurement systems, calibration services, and technical support to help you maintain the highest standards in manufacturing. Reach out today for a consultation!

The post What is the Difference Between CMM and VMM? appeared first on PMT Technologies.

]]>