Challenges: How to Break Through Bottlenecks of Traditional Measures

In the production process of large forklift parts, the challenge of quality inspection has always been a key factor constraining production efficiency and quality improvement. Especially in the processing of core parts such as axle case, traditional measurement methods have limited production efficiency, difficult quality control and high costs due to problems such as large size and heavy weight of parts and difficulty in accurately locating key parts. Especially in the flexible automated production mode, the limitations of traditional measurement tools are more prominent, creating an urgent need for companies to overcome these traditional measurement bottlenecks.

Solutions: PMT Portable Coordinate Measuring Machine

To address these challenges, a coordinate measuring arm combining high precision, flexibility, and intelligence – PMT Portable Coordinate Measuring Machine – has become a key breakthrough for the industry. With the high precision, multi-function and easy operation of the CMM arm, PMT portable measuring arm provides Hangcha Group with efficient and accurate measurement solutions. Meanwhile, the PMT arm CMM machine can adapt to various types of workpieces without the need for frequent tool changes or measurement parameter adjustments, significantly improving production efficiency while enhancing measurement accuracy with the help of portable CMM.

節(jié)臂圖-1741059700.webp)

Measurement Steps:

Preliminary Preparation: Analyze drawings, plan measurement plans, and edit the inspection procedures;

- Analyse the workpiece dimensions to ensure the accuracy of measurement details;

- Communicate with R&D personnel to resolve measurement disputes;

- Improve measurement efficiency by prioritizing the elimination of process issues.

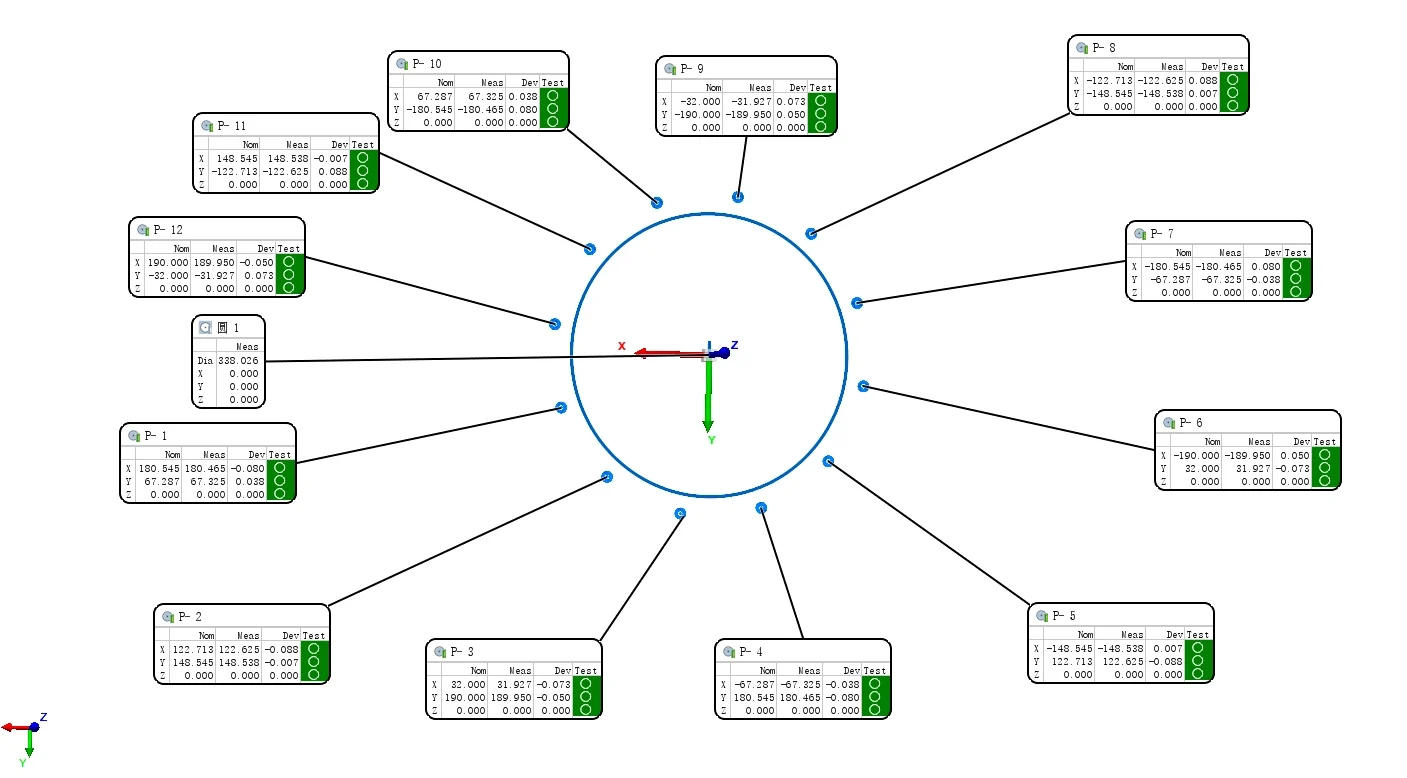

Measurement Process: Establish the coordinate system, set tolerances, evaluate features, and analyze measurement results;

- ?Simply evaluate flatness, distance, and angle;

- ?Establish the coordinate system and analyze the data tolerance;

- ?Use 3D model for data comparison to ensure position tolerances.

Report Generation: Generate customized reports, support multiple formats, provide 3D visualized data, enabling more efficient decision-making.

On-site Application and Customer Feedback: The 3D measuring arm breaks through bottlenecks and empowers production manufacturing.

At Hangcha Group’s production site, the technical team of Hangcha Group highly recognized the precise measurement capability of the PMT portable coordinate measuring machine. They noted that the PMT portable measuring arm not only significantly improved measurement efficiency and accuracy but also effectively reduced production costs. At the same time, the targeted technical exchanges and support provided by PMT engineers greatly enhanced Hangcha Group’s confidence and capability in controlling workpiece dimensions. Furthermore, PMT’s after-sales team further ensured the stable operation and continuous improvement of the portable measuring arm system with their efficient and professional service.

Future Prospect: Continuous Support, Never Stopping

Through years of development and challenges, measurement technology marked by portable CMM machine has been evolving from a simple quality inspection tool into a crucial pillar for supporting the intelligent transformation of enterprises. As a well-known manufacturer of arm type CMM, PMT will continue to uphold the spirit of technological innovation, assisting enterprises in achieving intelligent transformation and enhancing global competitiveness with its star CMM measuring arm. PMT aims to provide smarter, more efficient, and more precise measurement solutions with its metrology arm for the industrial vehicle manufacturing industry, becoming an indispensable “Smart Partner” in this field.