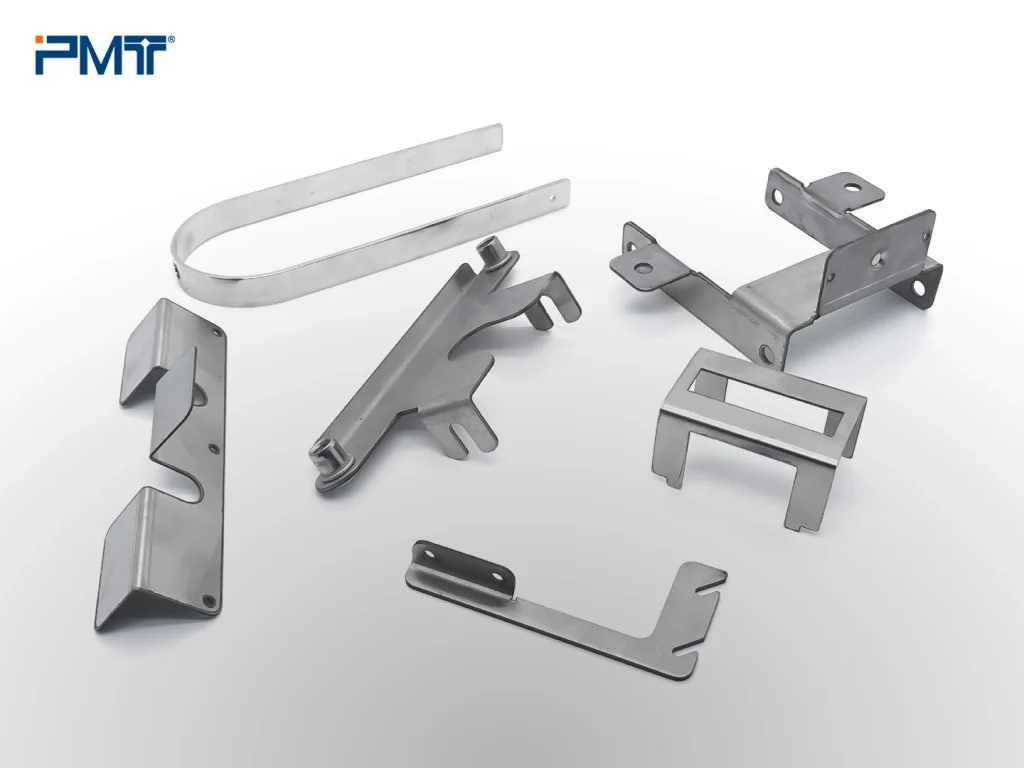

Sheet metal parts are widely used in industries such as automotive, aerospace, electronics, and construction. To ensure quality and accuracy, precise measurement during production and inspection is essential. However, because sheet metal is thin, flexible, and easily deformed, measuring it requires special care. Below, we will explore what to pay attention to when measuring sheet metal parts and how tools like the Portable Measuring Arm and Coordinate Measuring Machines (CMMs) can help.

Understand the Material Properties

To begin with, it is important to recognize that sheet metal has unique characteristics compared to thicker or more rigid parts. Its thin structure makes it more sensitive to pressure, temperature changes, and external force. This means that when measuring sheet metal, the wrong setup or technique can easily cause distortion, leading to inaccurate results. Therefore, the first step in successful measurement is to fully understand the properties of the material and adapt the method accordingly.

Control the Measurement Environment

Moving from material understanding to conditions, the environment in which measurements are taken plays a big role in accuracy. Sheet metal can expand, shrink, or warp when exposed to changes in temperature or humidity. Vibrations in the workshop can also affect sensitive measuring tools. For this reason, it is recommended to use a stable environment with controlled temperature and minimal external interference. Proper environmental control ensures consistent and reliable data.

Choose the Right Measuring Tools

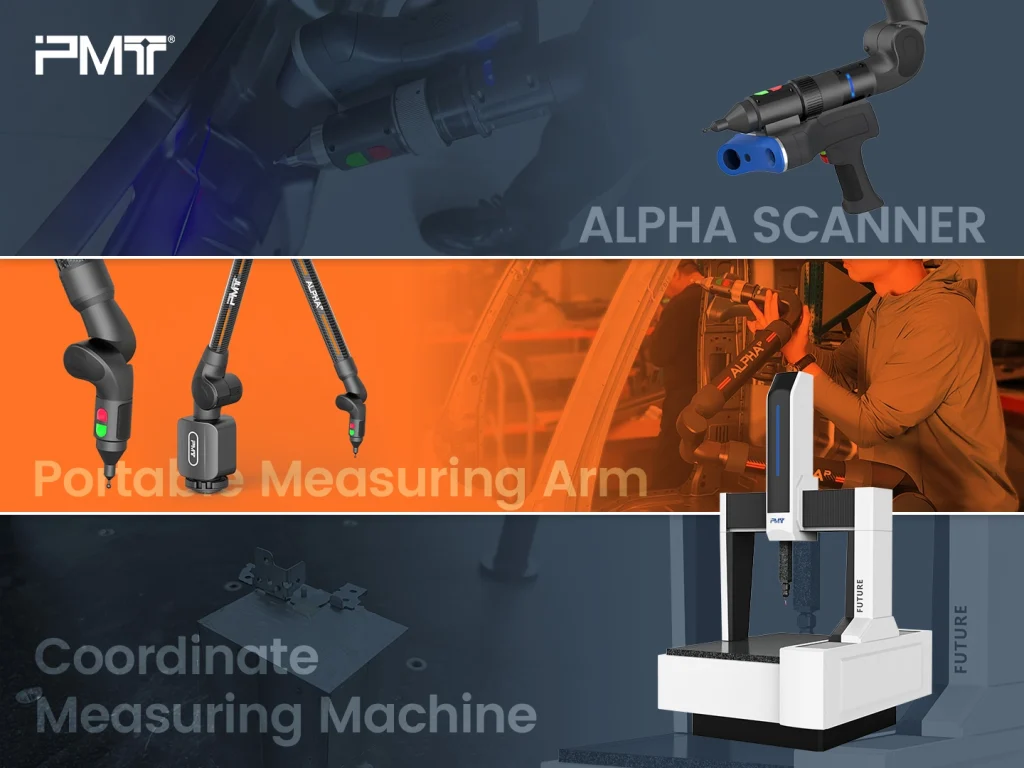

Another key factor is selecting the right measuring equipment. Traditional gauges and calipers may not always deliver the precision required for complex sheet metal parts. Instead, advanced solutions such as portable measuring arms and coordinate measuring machines provide higher accuracy and flexibility. Portable Measuring Arms allow operators to measure large or irregular parts directly on the shop floor, while?CMMs?are ideal for highly detailed dimensional inspections. Choosing the right tool depends on the shape, size, and tolerance requirements of the sheet metal part.

Prevent Deformation During Measurement

As we shift from tools to technique, preventing deformation becomes critical. Even light pressure from a probe or clamp can bend thin sheet metal, resulting in false readings. To avoid this, non-contact methods, such as laser scanning attached to a portable measuring arm, can be used for delicate areas. If contact methods are required, ensure the part is properly supported to maintain its natural shape during inspection. Handling the part carefully throughout the process minimizes errors caused by deformation.

Pay Attention to Clamping and Positioning

Beyond the measuring process itself, clamping and positioning also deserve careful consideration. Incorrect fixturing can distort the part before measurement even begins. Fixtures should be designed to hold the part securely without adding stress or force that changes its geometry. Positioning must also allow clear access for the measuring tool to reach all critical points. A well-designed setup improves efficiency and accuracy, especially when working with complex or large sheet metal structures.

Use Consistent Measurement Standards

Finally, consistency in measurement standards ensures reliable results across different processes and teams. Always follow industry standards, customer requirements, or company guidelines when inspecting sheet metal parts. Aligning with these standards not only reduces the chance of error but also ensures that measurements can be compared and verified. Documenting the process and using the same reference points during each inspection helps maintain quality control over time.

Conclusion

Measuring sheet metal parts requires more than just accurate equipment—it demands attention to material properties, environment, clamping, and technique. By choosing the right tools, such as Portable Measuring Arms and Coordinate Measuring Machines, manufacturers can achieve precise results while avoiding common challenges like deformation. Careful planning and consistent standards will help maintain high quality in sheet metal production.

If you are looking for a reliable coordinate measuring machines supplier, PMT offers advanced solutions with strong expertise in measurement technology. Contact PMT today to learn more about how our products can support your quality control needs.