Coordinate Measuring Machines (CMMs) are essential tools in modern manufacturing. They provide precise measurements that ensure parts meet strict design and quality standards. However, like any measuring instrument, a CMM can lose accuracy over time if it is not properly maintained. This is why CMM calibration is so important. Regular calibration guarantees accuracy, supports compliance with industry standards, and prevents costly production errors.

Understanding CMM Calibration

To begin, it is important to understand what CMM calibration means. Calibration is the process of comparing the measurements of a CMM?with known standards to verify its accuracy. If any deviation is found, adjustments are made to bring the machine back to the required precision level.

In simple terms, calibration ensures that the measurements your CMM provides are both accurate and reliable. Without it, even the best coordinate measuring machines can drift out of tolerance, leading to errors in quality control.

Why CMM Calibration Matters for Quality Assurance

One of the main reasons calibration is so critical is its direct impact on quality assurance. Manufacturers rely on CMMs to validate that every part produced meets design specifications. If the CMM is inaccurate, faulty parts can pass inspection and reach customers.

This not only damages trust but can also result in expensive recalls, safety risks, and production delays. With regular calibration, companies can ensure their CMMs deliver trustworthy results, maintaining consistency across all measurement tasks.

Compliance With Industry Standards

In addition to quality assurance, CMM calibration is essential for meeting industry standards. Many sectors, such as aerospace, automotive, and medical device manufacturing, have strict requirements for measurement accuracy. Standards like ISO and ASME require companies to provide documented proof that their measurement equipment is properly calibrated.

Without calibration records, companies may fail audits, lose certifications, or face legal and contractual consequences. Regular calibration therefore helps manufacturers not only maintain precision but also stay compliant with international regulations.

Reducing Costly Errors and Downtime

Another reason calibration is important is the financial impact of measurement errors. If a CMM produces inaccurate data, entire production batches may be rejected, reworked, or recalled. This results in wasted time, higher costs, and potential loss of business.

By keeping CMMs calibrated, manufacturers minimize these risks. A well-calibrated machine prevents incorrect measurements, reduces rework, and lowers scrap rates. In addition, calibration helps detect potential machine issues early, avoiding unexpected downtime and repair costs.

How Often Should CMMs Be Calibrated?

The frequency of calibration depends on several factors, including how often the CMM is used, the type of parts being measured, and the environmental conditions of the workspace. For example, machines used in high-precision industries or harsh environments may require more frequent calibration.

While manufacturers often follow annual calibration schedules, best practices involve monitoring usage and performance closely. Any signs of measurement drift or changes in machine performance should prompt recalibration to maintain accuracy.

The Role of Professional Calibration Services

It is also important to note that calibration should always be carried out by trained professionals using certified equipment. Professional calibration services follow international standards and use traceable measurement tools to ensure reliable results.

Attempting to calibrate a CMM without the right knowledge or equipment can lead to further errors. Partnering with qualified providers guarantees that the machine continues to perform at its highest level, giving manufacturers peace of mind.

Building a Culture of Precision

Ultimately, CMM calibration is not just a technical requirement but a part of building a culture of precision and quality in manufacturing. By treating calibration as a routine necessity, companies reinforce their commitment to accuracy, reliability, and customer satisfaction.

In today’s competitive industries, where tolerances are tighter and demands are higher, a calibrated CMM can make the difference between meeting client expectations and falling short.

Conclusion

In summary, the importance of CMM calibration cannot be overstated. It ensures accuracy in measurements, supports quality assurance, maintains compliance with industry standards, reduces costly errors, and protects business reputation. By investing in regular calibration, manufacturers safeguard their operations and strengthen their competitive edge.

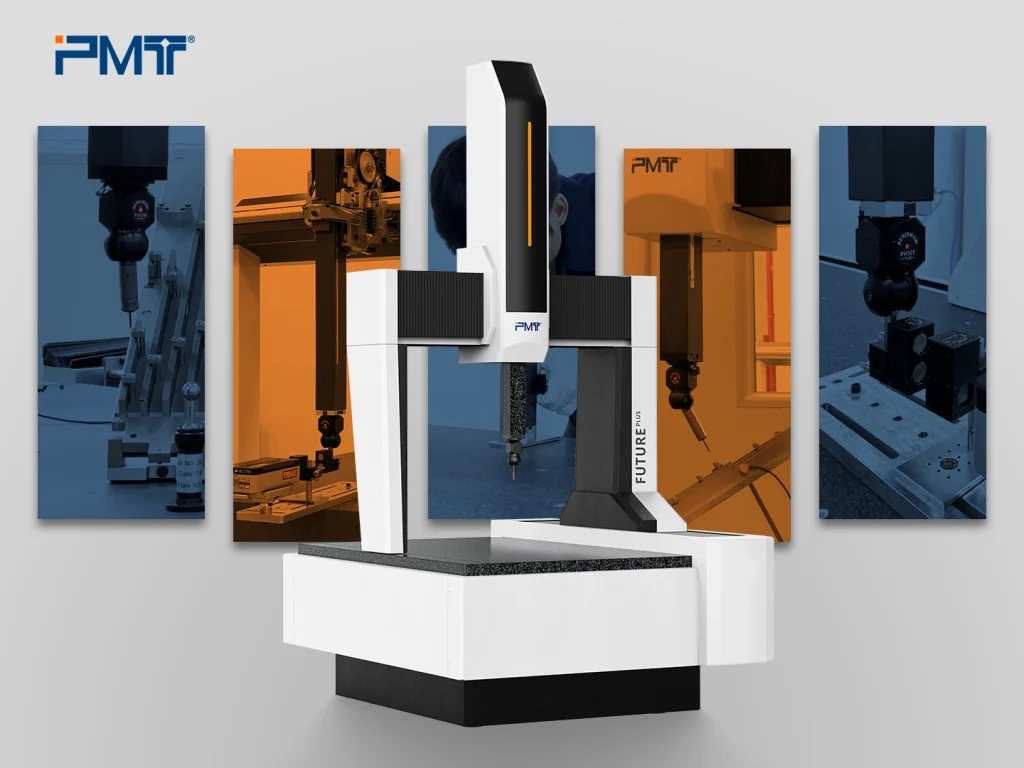

If your company is looking for reliable solutions in precision measurement, PMT is a trusted coordinate measuring machines supplier. With expertise in portable measuring arms, laser scanners, and advanced CMMs, PMT provides high-quality products and services that help manufacturers maintain accuracy and efficiency. Get in touch today to learn how PMT can support your measurement needs.